Existing building anti-floating system based on embedded self-propelled anchor rods and construction method thereof

A technology of existing buildings and construction methods, applied in construction, infrastructure engineering, infrastructure repair and other directions, can solve problems such as cracking and seepage, easy to float, damage to supporting structures, etc., to increase the contact area and increase the viscosity. The effect of knotting ability and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

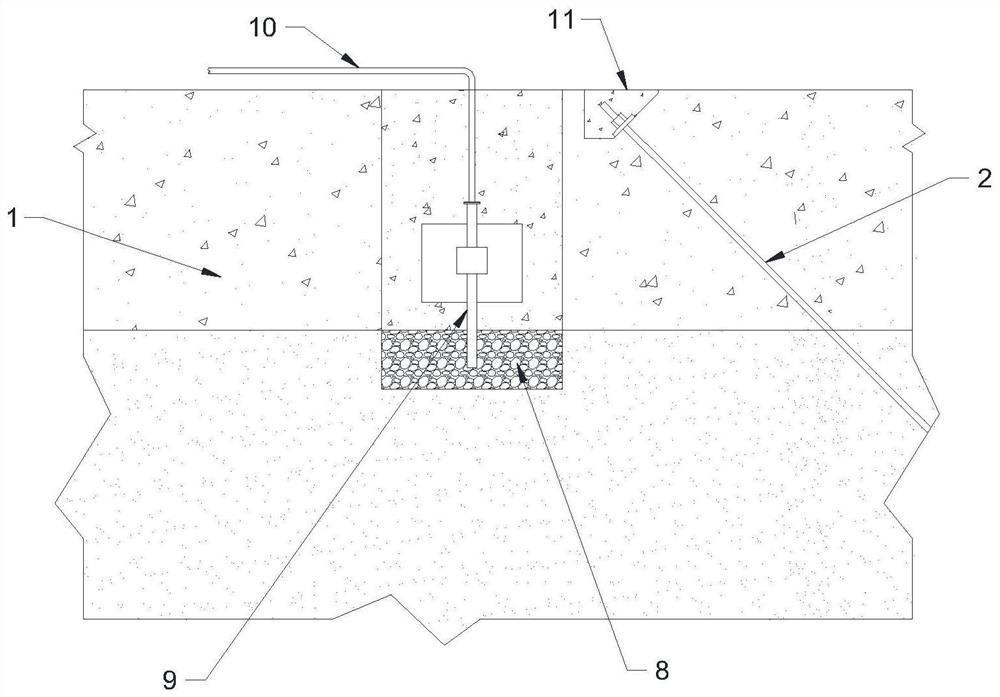

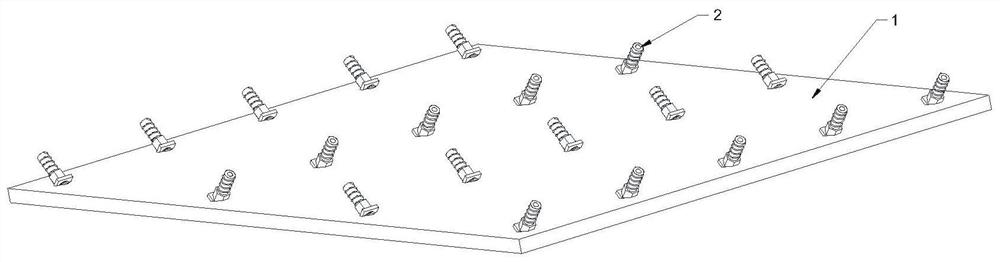

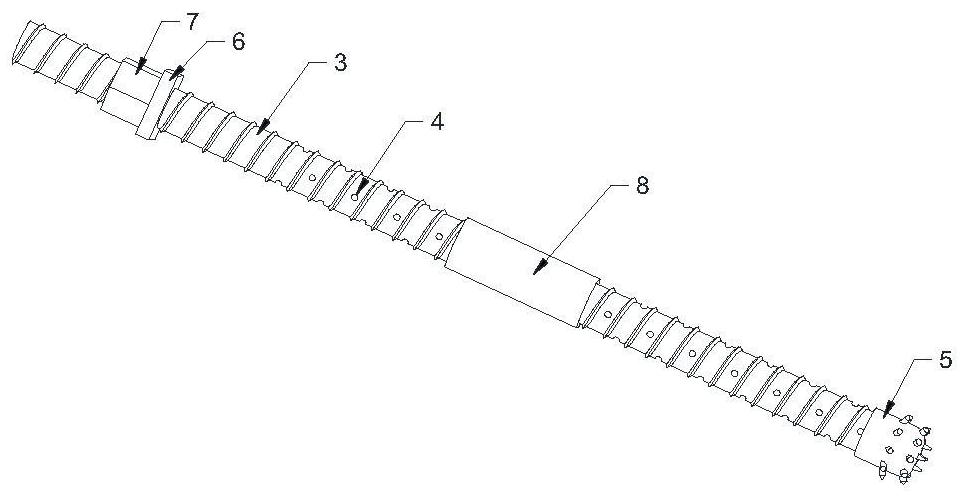

[0036] See Figure 1-6 However, the existing building floating system based on the embedded self-joined anchor includes an anchor group that is applied to the existing building anti-floating bottom plate 1, and the anchor population includes a plurality of self-propelled floating anchor rods 2, each self The angle between the in-plane anti-floating anchor 2 and the plane of the anti-floating bottom plate 1 is 40-75 degrees; the auto-circulating anchor rod 2 in the anchor group is arranged in a matrix, and each row is self-entered. The floating anchor 2 is disposed in parallel, each column is adjacent to two auto-floating anchor rods, and also includes a pressure relief tube 9 inserted on the anti-floating bottom plate 1, and the bottom end end of the pressure relief tube 9 is located Floating bottom plate 1, the other end is connected to the building outlet pool or municipal rain sewage pipe network.

[0037] In the present embodiment, the construction method of the existing buildi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com