Eccentric structure-based stone material crusher with fine grinding function

A technology of fine grinding and eccentric structure, applied in the field of stone processing, can solve the problems of a lot of labor, affecting production, low crushing efficiency, etc., to achieve smooth grinding, improve crushing efficiency, and facilitate subsequent processing and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

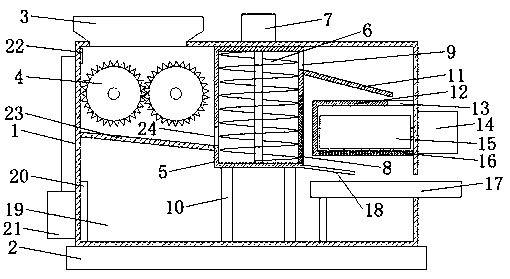

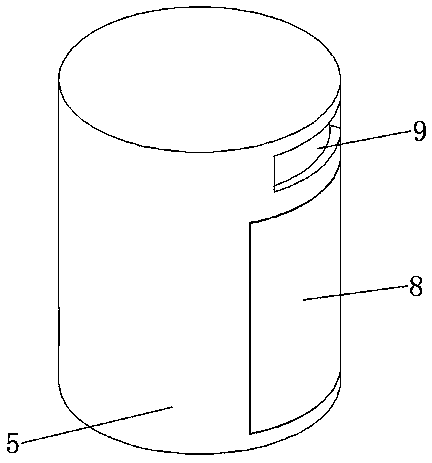

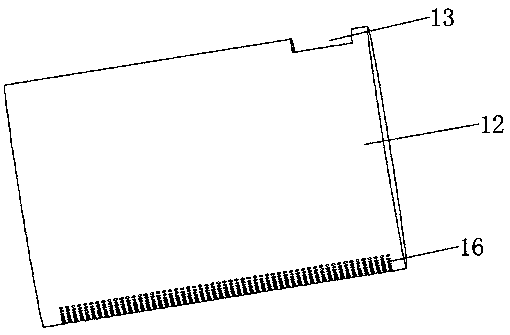

[0021] Please refer to the figure, in the embodiment of the present invention, a stone crusher with eccentric structure and fine grinding includes a casing 1, a shock absorbing base 2, a feed hopper 3 and a crushing roller 4; the shock absorbing base 2 is fixedly mounted on the shell On the bottom of the body 1, the shock-absorbing base 2 is a rubber pad, which plays a role of shock absorption and buffering after the casing 1 is placed on the ground, reducing the noise generated during operation and protecting the equipment; at the left end of the top of the casing 1 The top is connected to the feed hopper 3, and the stone is loaded into the shell 1 from the feed hopper 3, and two horizontal crushing rollers 4 that cooperate with each other are installed in the shell 1 directly below the feed hopper 3. The crushing roller 4 is connected to the driving device through the transmission mechanism, so that the crushing roller 4 rotates, and crushes the falling stones; below the crus...

Embodiment 2

[0025] On the basis of Embodiment 1, the bottom of the housing 1 is set as a water tank 19, which is filled with spray water, and a circulating pump 21 is installed at the bottom of the water tank 19, and the water inlet of the circulating pump 21 is covered with a filter. The net 20 is used to filter impurities in the water. The outlet of the circulation pump 21 is connected to the pipeline, and the other end of the pipeline is connected to the spray port 22 located above the crushing roller 4. Water is sprayed on the crushing roller 4. On the one hand, the crushing roller 4. Cool down, on the other hand, reduce the dust during crushing, and maintain the surrounding environment; after water and stones enter the separation cylinder 5, the water flows out through the powder discharge mesh plate 8, and then flows back to the water tank 19 through the material guide mesh plate 18 Inside, the water is recycled.

[0026] During the stone crushing process, the stone is firstly crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com