Steel cable cutting mechanism

A steel cable cutting technology, applied in the field of steel cable cutting mechanism, can solve the problems of low production efficiency, time-consuming and laborious, etc., and achieve the effect of improving production efficiency, ensuring accuracy, and facilitating subsequent processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

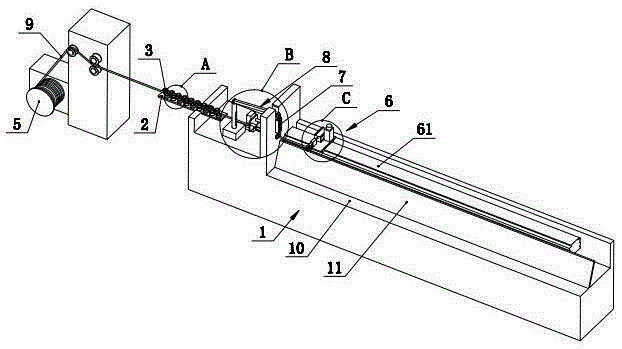

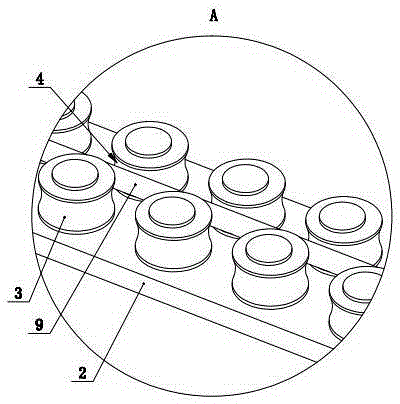

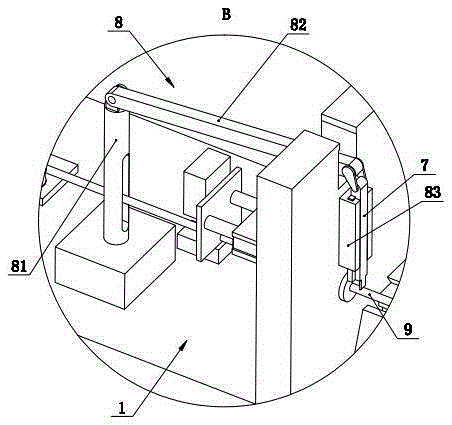

[0017] Such as figure 1 , 2 , 3, 4, and 5 show a cable cutting mechanism, including a frame 1, a flat plate 2 is fixed on the frame 1, and two rows of linear dislocation are installed on the flat plate 2. The provided rollers 3 form a cable straightening channel 4 between two rows of rollers 3, and the frame 1 is provided with a cable output roller 5 in front of the input end of the cable straightening channel 4. A cable stretching traction device 6 is arranged behind the output end of the cable straightening channel 4, and a steel cable cutting knife 7 and The drive mechanism 8 for driving the cable cutter 7 to realize the cutting of the cable 9, the drive mechanism 8 includes a cable cutter drive cylinder 81 and a balance plate 82, the middle of the balance plate 82 is hinged Fixed on the frame 1, the said cable cutter drive cylinder 81 is vertically installed and fixed on the frame 1, and its output end abuts against one end of the balance plate 82, and the said frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com