Profile steel splicing, machining and welding process

A welding process and section steel technology, applied in the field of section steel splicing processing and welding technology, can solve the problems of inability to adjust the section steel, unable to clamp and position the section steel, and prone to deviation of the section steel. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

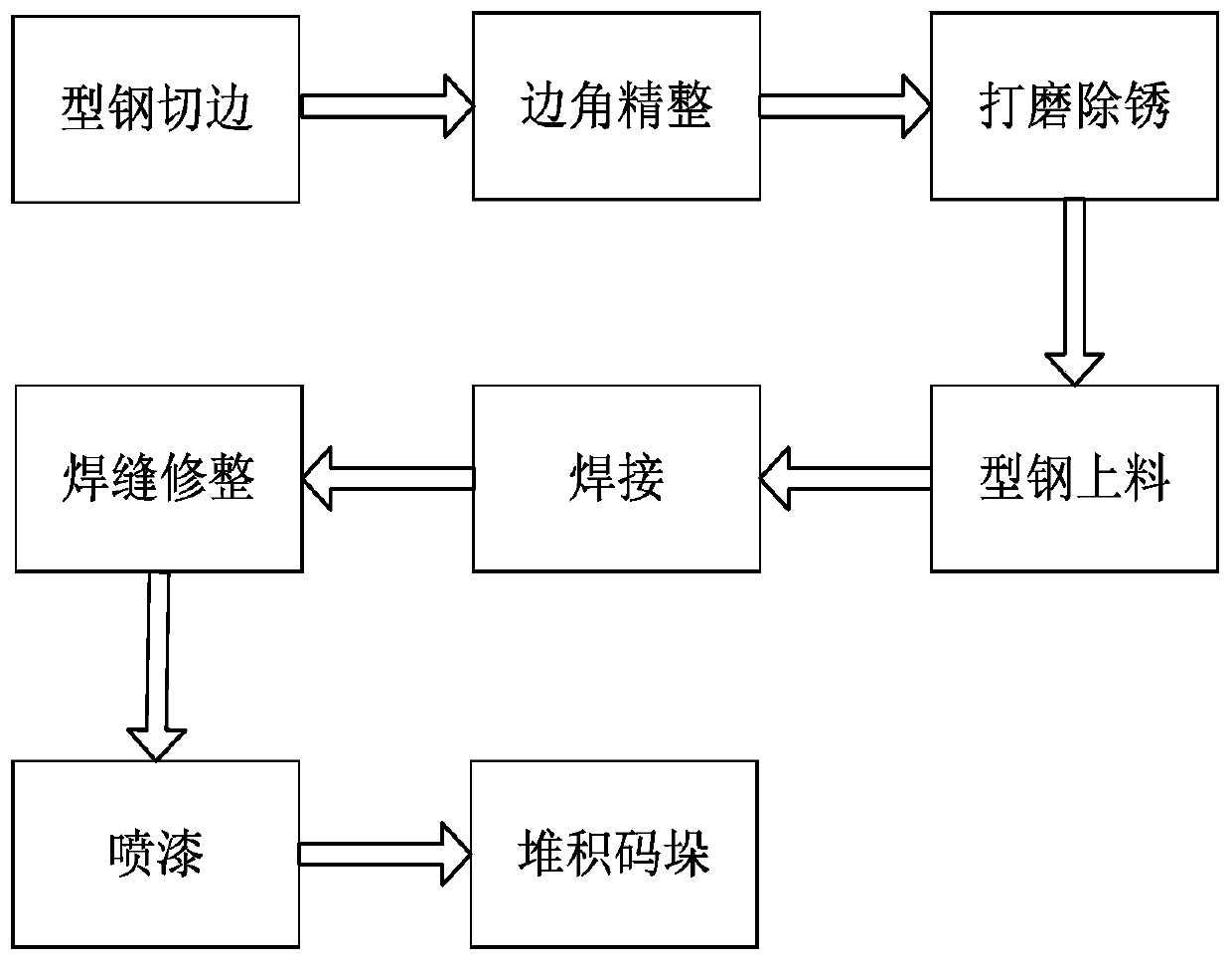

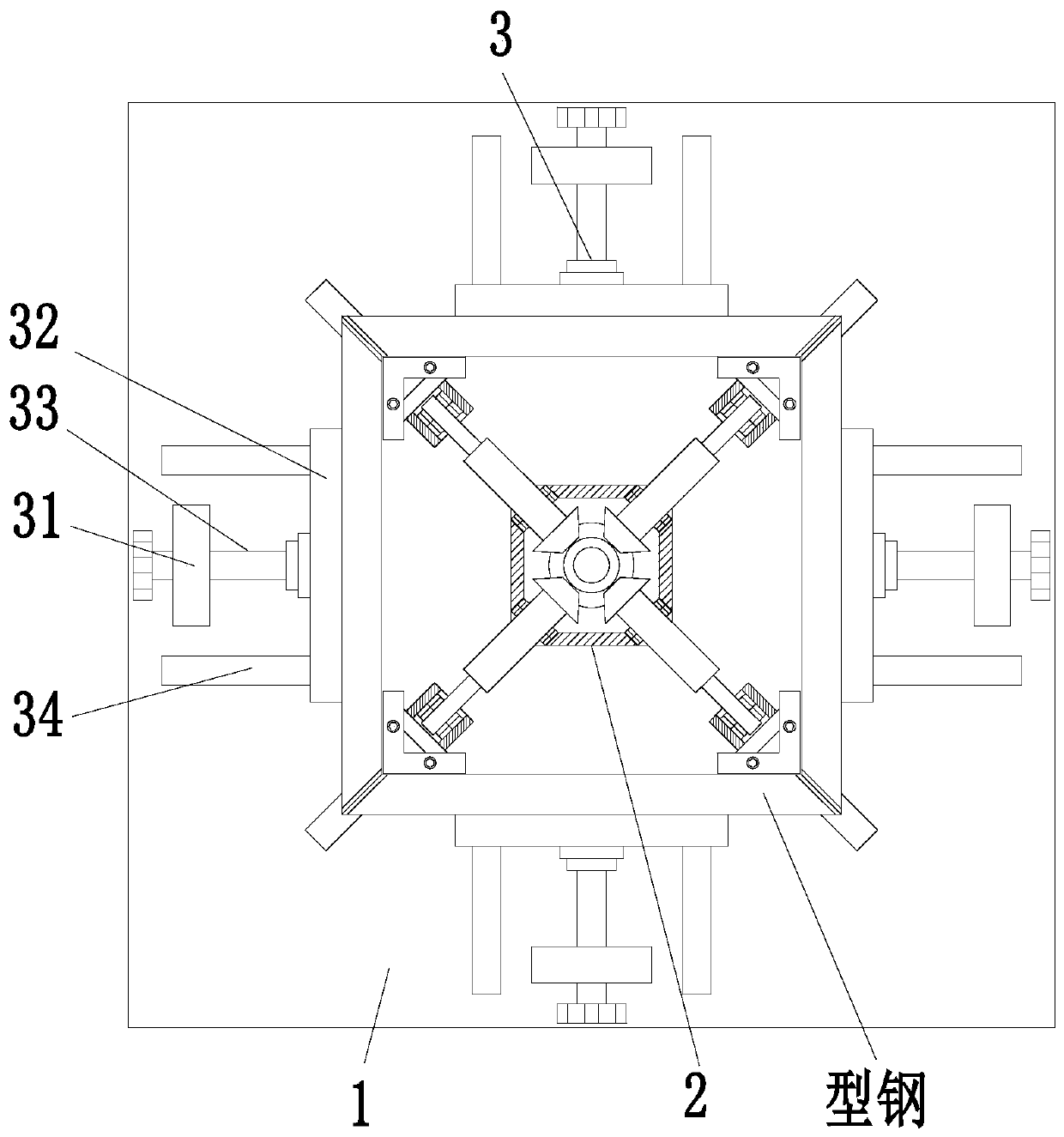

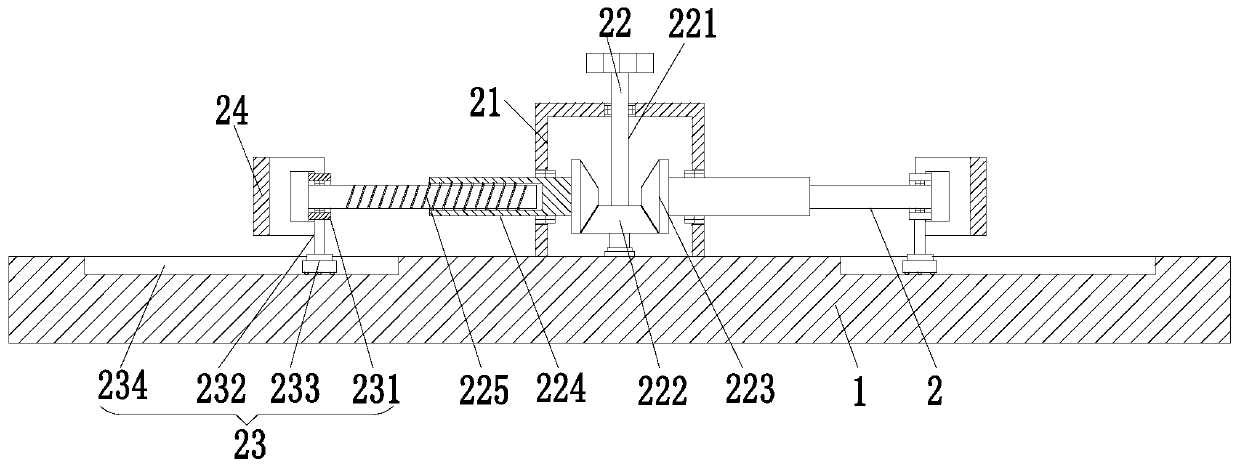

[0035] Such as Figure 1 to Figure 4 Shown, a kind of section steel splicing processing welding process comprises the following steps:

[0036] S1. Cutting edge of section steel: manually cut the end of section steel, and the end of section steel after cutting is at an angle of 45°;

[0037] S2, trimming of corners: manual trimming of phenomena such as hemming and warping at the end of the section steel after edge trimming in step S1;

[0038] S3. Grinding and derusting: Grinding the profiled steel in step S2 with a grinding wheel to remove rust, burrs and other defects on the profiled steel surface;

[0039] S4, section steel feeding: install the section steel polished in step S3 on the upper end of the inner support device 2, and the outer suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com