Noble metal and base material compound embossing process method and process product thereof

A process method and precious metal technology, applied in the field of precious metal and substrate composite embossing process method and its process products, can solve the problems of weight reduction, precious metal waste, and insufficient production efficiency, and achieve reduced defect rate, tight integration, and attached strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

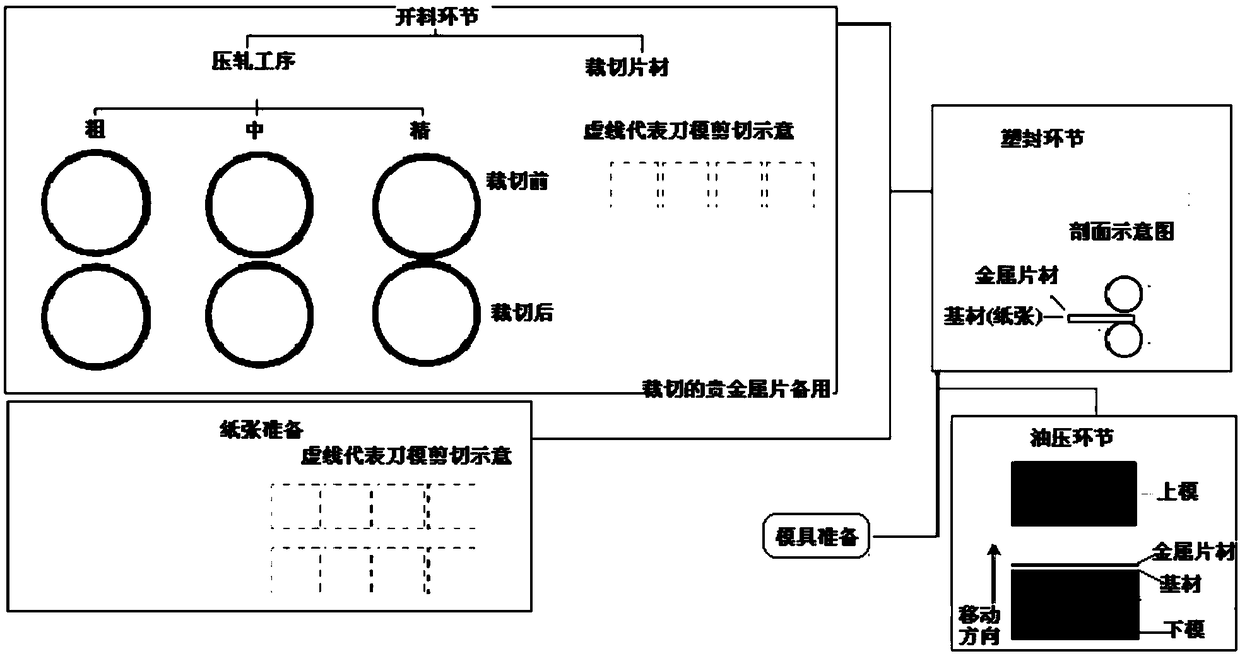

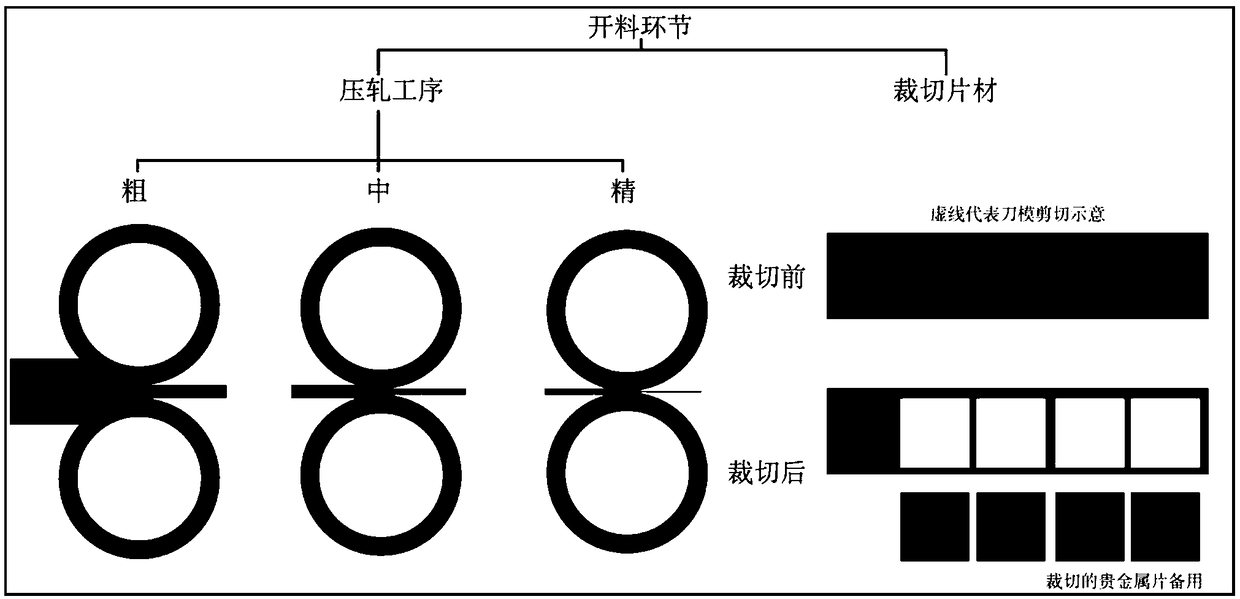

[0041] See attached figure 1 , a kind of precious metal and base material composite embossing technique method makes the stamp that paper base and precious metal sheet are combined, and this method comprises the following steps:

[0042] see Figure 1a , step 1, the cutting process, used to obtain the sheet and cut the sheet, including the rolling process and the cutting process, the rolling process obtains a sheet with a preset thickness through rough, medium and fine rolling, The sheet cutting process cuts the rolled sheet through a knife die, cutting through an engraving knife mold, an etching knife mold, a precision round roller knife mold or a QDC metal mold. Of course, other technological means well known in the art are also possible. Also within the protection scope of the present invention, the thickness of the sheet is 0.0005mm;

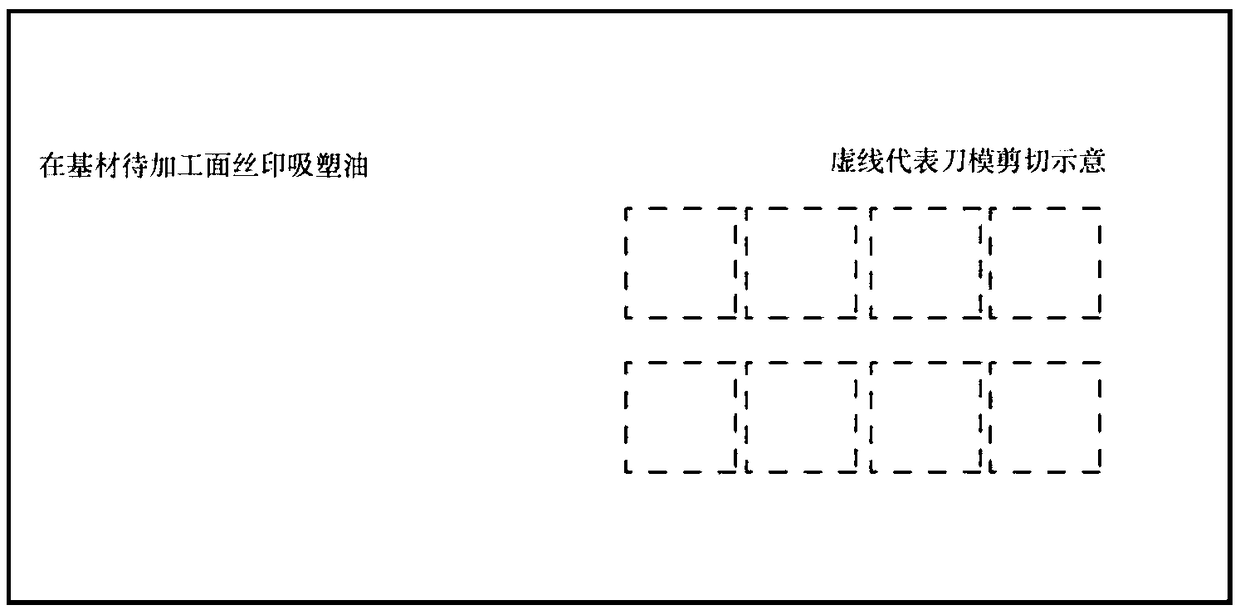

[0043] see Figure 1b, Step 2, prepare the paper base, including attaching blister oil to the surface of the paper base to be processed ...

Embodiment 2

[0054] A kind of precious metal and base material composite embossing process method makes the stamp of PET base material partial composite gold flake or other precious metal, and this method comprises the following steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com