Preparation method of heat-conducting fiber reinforced high-heat-conducting graphite heat radiating fin

A technology of high thermal conductivity graphite and thermal fiber, applied in heat exchange equipment, heat exchange materials, lighting and heating equipment, etc., can solve the problem of poor strength and mechanical properties of pure heat conduction graphite sheet, difficulty in meeting the use requirements, graphite dust falling off, etc. problems, to achieve the effect of easy subsequent processing and use, light weight and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

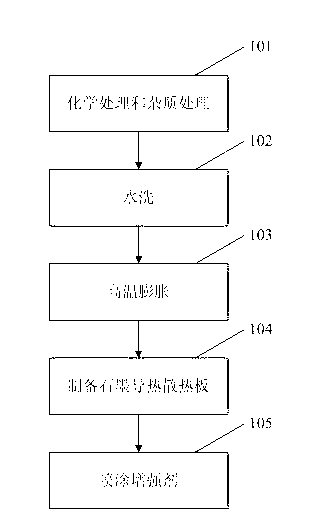

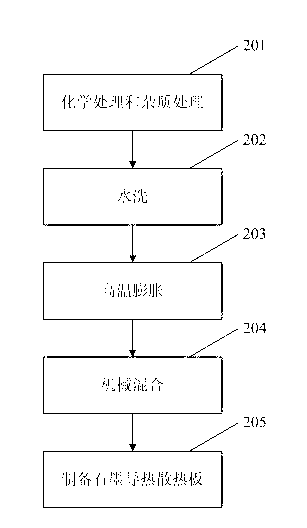

Method used

Image

Examples

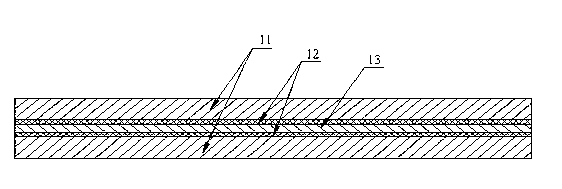

Embodiment 1

[0041]Select natural graphite powder and graphite short fiber with a carbon content of 98% and a particle size of 100 μm, and the mass ratio of graphite powder to graphite short fiber is 8:1. Put the natural graphite powder into the acid treatment solution for chemical treatment and impurity treatment, wash the treated graphite powder with water, then put it into the graphite expansion furnace for high temperature expansion, and then cool slowly after high temperature expansion. Mix the treated graphite powder according to the ratio of graphite powder: graphite fiber = 3:1 parts by mass, and then use graphite coil production equipment to make graphite with a density of 1.2g / cm3 and a thickness of 0.5mm for heat conduction and heat dissipation plate. Then mix the graphite short fibers in the water-based pressure-sensitive adhesive, stir and disperse evenly with a high-strength disperser, and spray evenly on the graphite heat sink. Bonding, and applying a certain pressure, fina...

Embodiment 2

[0043] Select natural graphite powder and carbon fiber with a carbon content of 96% and a particle size of 200 μm, and the mass ratio of graphite powder to carbon fiber is 8:1. Put the natural graphite powder into the acid treatment solution for chemical treatment and impurity treatment, wash the treated graphite powder with water, then put it into the graphite expansion furnace for high temperature expansion, and then cool slowly after high temperature expansion. Mix the treated graphite powder according to the ratio of graphite powder: graphite fiber = 10:1 parts by mass, and then use graphite coil production equipment to make a graphite heat-conducting and heat-dissipating plate with a thickness of 1.2g / cm3 and a thickness of 1.0mm. Then mix the carbon fiber in the water-based pressure-sensitive adhesive, stir and disperse evenly with a high-strength disperser, then spray evenly on the graphite heat sink, and after it is completely dry, quickly bond with another piece of the...

Embodiment 3

[0045] Choose natural graphite powder and carbon fiber cloth with a carbon content of 98% and a particle size of 500 μm, and the mass ratio of graphite powder to carbon fiber cloth is 7:1. Put the natural graphite powder into the acid treatment solution for chemical treatment and impurity treatment, wash the treated graphite powder with water, then put it into the graphite expansion furnace for high temperature expansion, and then cool slowly after high temperature expansion. The treated graphite powder is mixed according to the ratio of graphite powder: graphite fiber = 6:1 parts by mass, and then passed through graphite coil production equipment with a density of 0.8g / cm3 and a thickness of 0.5mm. Then, one side of the prepared graphite heat sink is evenly coated with water-based pressure-sensitive adhesive. After it is completely dry, quickly coat the carbon fiber cloth on the water-based pressure-sensitive adhesive, and then apply the other piece of graphite heat sink coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com