Process for preparing electric silver/graphite contact material by nano technique

An electrical contact material and nanotechnology technology, which is applied in the field of preparing silver/graphite electrical contact materials by nanotechnology, can solve the problems of uneven distribution of graphite, high material yield, low production cost, etc. The effect of high conductivity and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

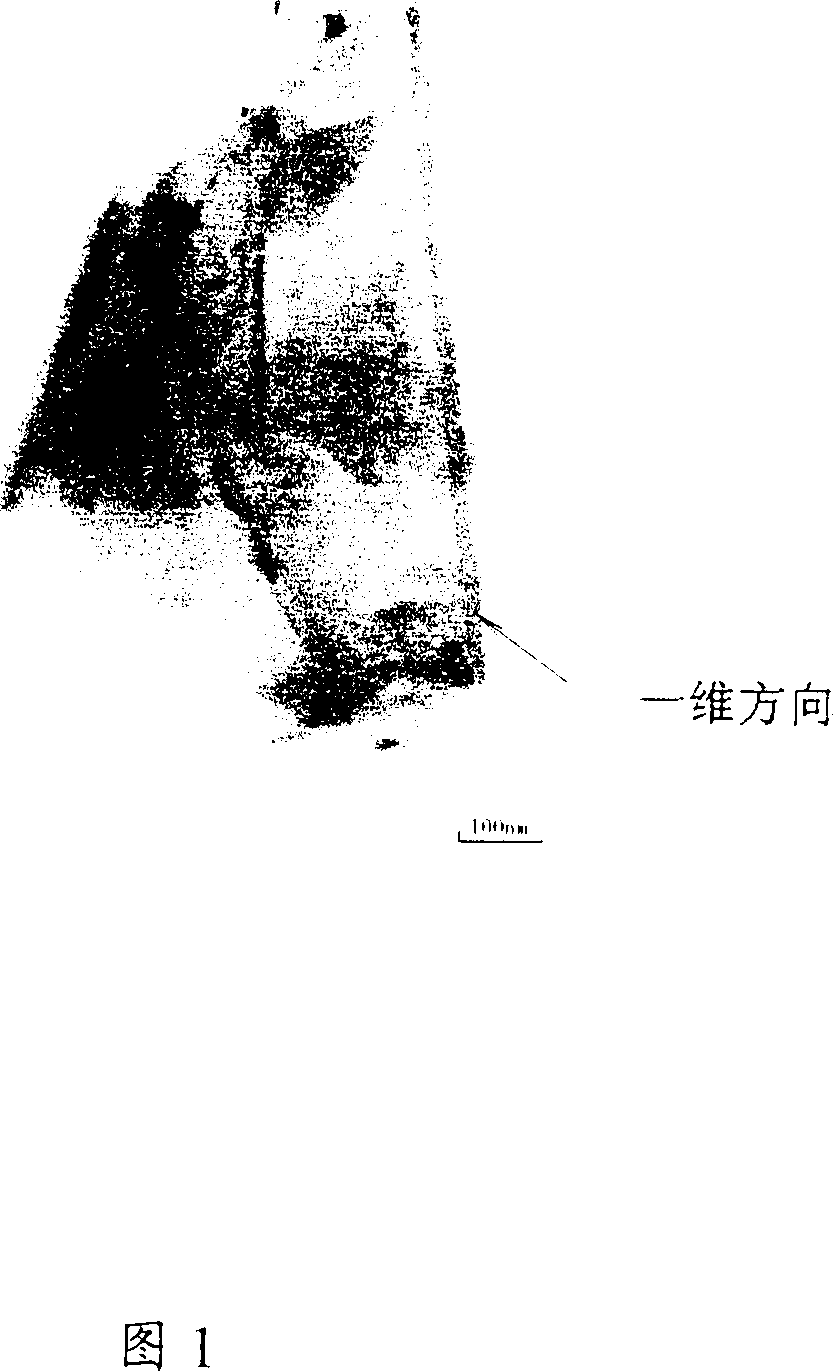

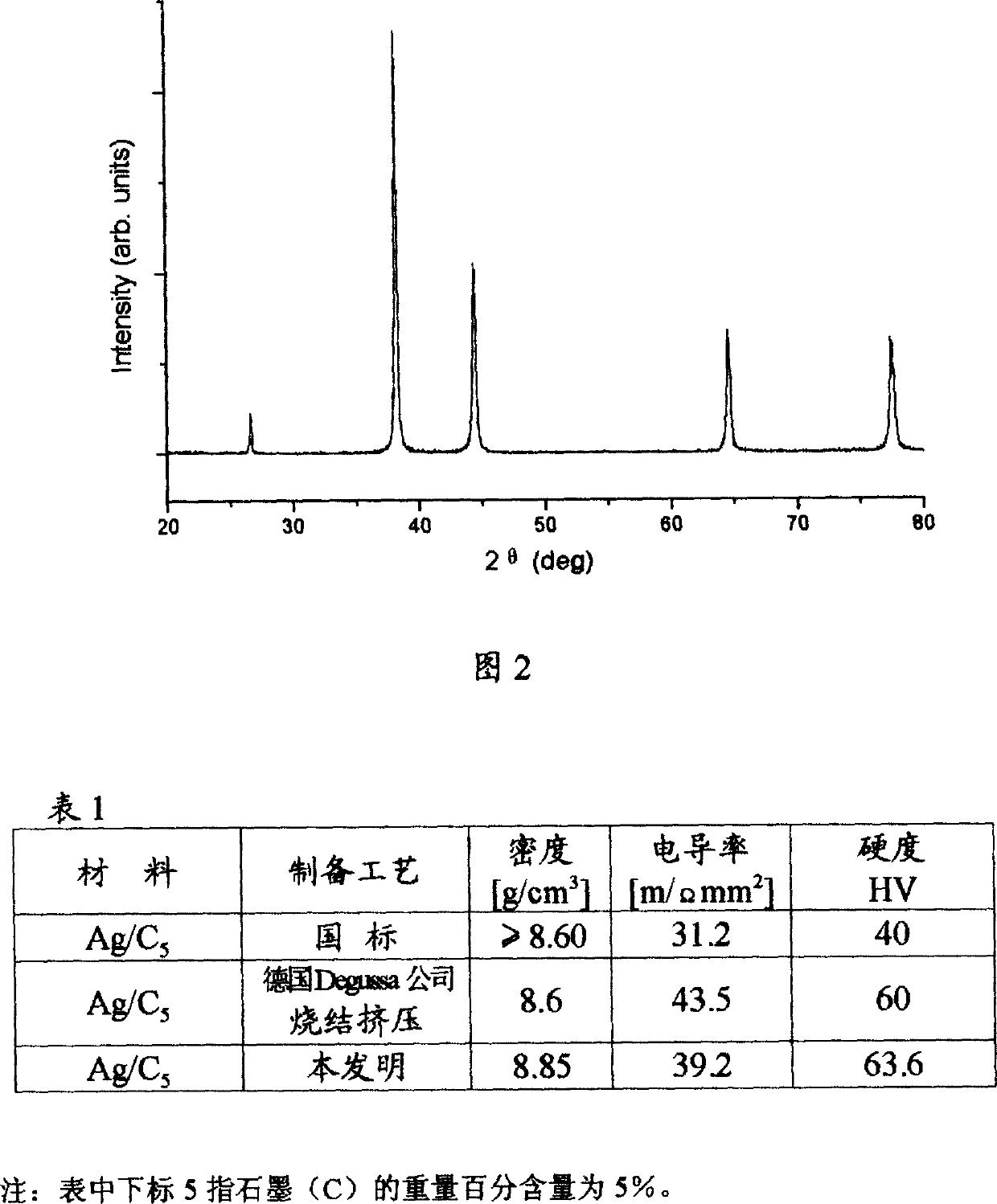

[0030] Embodiment 1. Utilize nanotechnology to prepare silver / graphite electric contact material

[0031] Get commercially available coarse graphite powder in a planetary high-energy ball mill using steel balls and a spherical tank with a rotating speed of 100rpm, a ball-to-powder ratio of 10:1, ball milling for 40 hours, take it out from the spherical tank, and dry it in a desiccator at 80°C. Obtain dry nano-graphite powder. Then add 2.5g of nano-graphite powder into the reaction vessel, and slowly add 920ml of silver nitrate solution complexed with ammonia water to a pH value of 10 and a concentration of 0.5 mol / liter into the reaction vessel while stirring to hydrate 30ml Hydrazine and 50ml of deionized water were configured to form a hydrazine hydrate solution, which was added to the reaction vessel by liquid phase spraying to obtain silver / graphite nano-coated powder. The coated powder was washed with water until neutral, and then dried in a desiccator at 160° C. to obta...

Embodiment 2

[0032] Embodiment 2. Utilize nanotechnology to prepare silver / graphite electric contact material

[0033] Get commercially available coarse graphite powder in a planetary high-energy ball mill using steel balls and a spherical tank with a rotating speed of 200rpm and a ball-to-powder ratio of 25:1, ball mill for 20 hours, take it out from the spherical tank, and dry it at 80°C in a desiccator. Obtain dry nano-graphite powder. Then add 2.5g of nano-graphite powder into the reaction vessel, and slowly add 460ml of silver nitrate solution complexed with ammonia water to a pH value of 10 and a concentration of 1 mol / liter into the reaction vessel while stirring to hydrate the 35ml Hydrazine and 60ml of deionized water were configured to form a hydrazine hydrate solution, which was added to the reaction vessel by spraying the liquid phase to obtain silver / graphite nano-coated powder. The coated powder was washed with water until neutral, and then dried in a desiccator at 120° C. t...

Embodiment 3

[0034] Embodiment 3. Utilize nanotechnology to prepare silver / graphite electric contact material

[0035] Get commercially available coarse graphite powder in a planetary high-energy ball mill using steel grinding balls and a spherical tank with a rotating speed of 250rpm and a ball-to-powder ratio of 30:1, ball mill for 10 hours, take it out from the spherical tank, and dry it at 80°C in a desiccator. Obtain dry nano-graphite powder. Then add 2.7g of nano-graphite powder into the reaction vessel, slowly add 80ml of silver nitrate solution complexed with ammonia water to a pH value of 11, and a concentration of 5 mol / liter into the reaction vessel, and at the same time stir to hydrate 40ml Hydrazine and 70ml of deionized water were configured to form a hydrazine hydrate solution, which was added to the reaction vessel by spraying the liquid phase to obtain silver / graphite nano-coated powder. The coated powder was washed with water until it became neutral, and then dried in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com