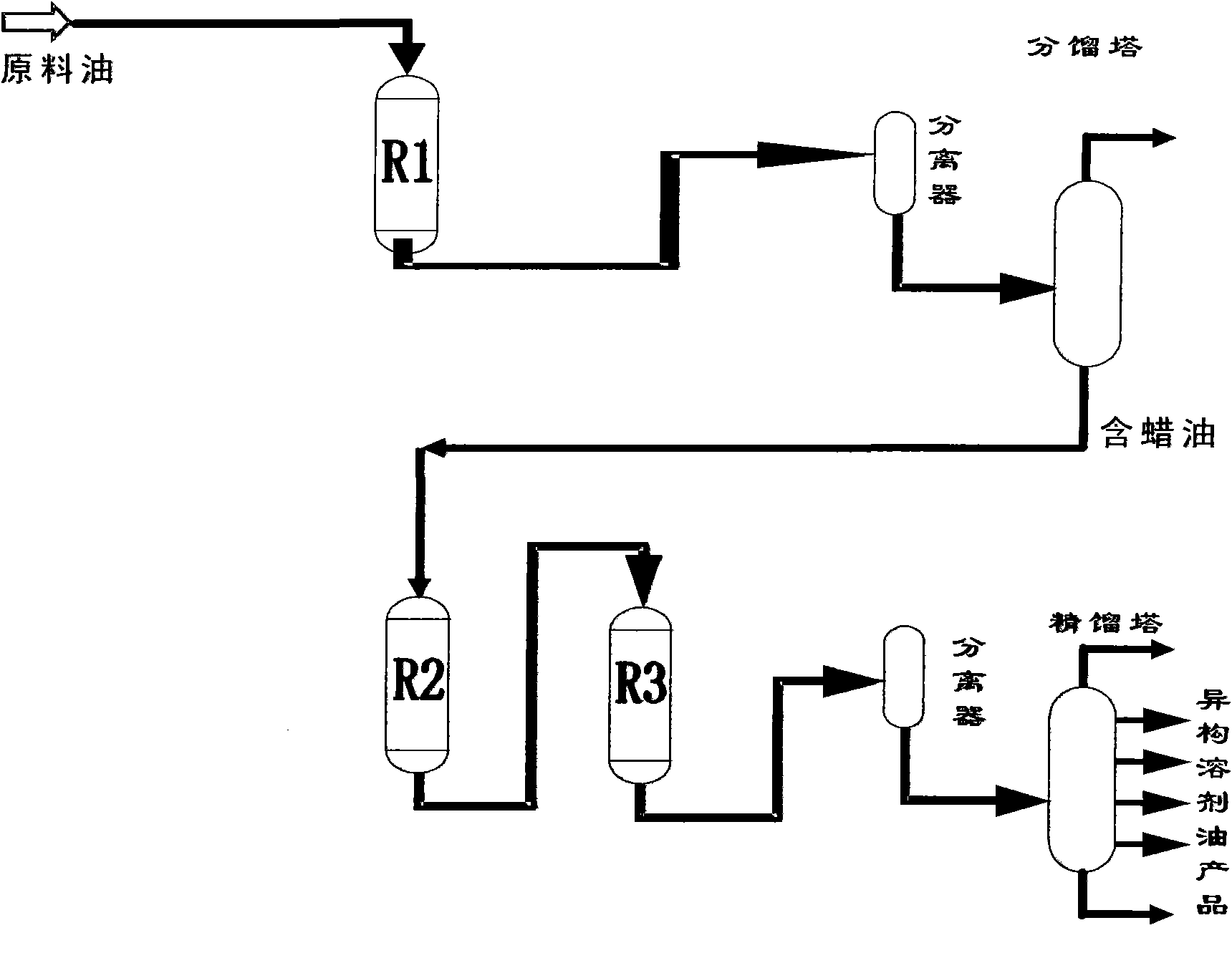

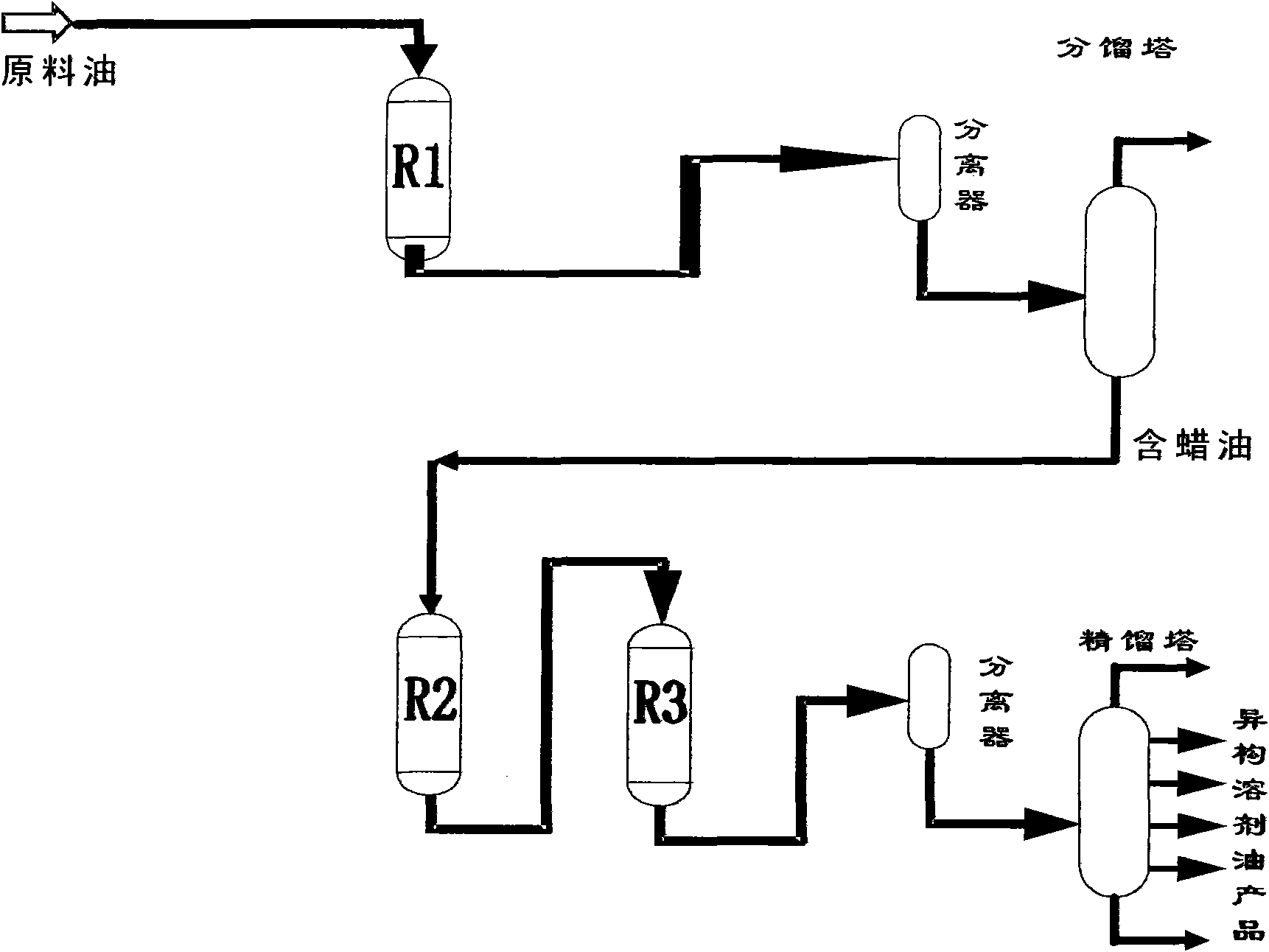

Method for manufacturing isoparaffin solvent oil

A technology for isoparaffin solvent oil and production method, which is applied in the treatment of hydrocarbon oil, the petroleum industry, and the hydrogenation of aromatic hydrocarbons, etc., can solve the problems of strict limitation of raw material properties and limited scope, and achieves enhanced raw material adaptability and product quality. The effect of good quality and strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Process raw material A in Table 1, use the catalyst in Table 2 in the hydroprocessing reaction zone, use the catalyst in Table 3 in the hydroisomerization reaction zone, and prepare the hydrogenation and supplementary hydrofining catalyst according to the method in Example 1 of CN00123149.9 , the catalyst is supported by alumina, containing MoO 3 4.5wt%, NiO 29wt%, pore volume 0.31ml / g, specific surface area 180m 2 / g. The results obtained are shown in Table 4. The hydrogenation treatment catalyst is vulcanized by the conventional method, and the hydrogenation treatment reaction is carried out, and the hydroisomerization and hydrogenation supplementary refining catalyst is reduced by the conventional method, and the isomerization or refining reaction is carried out.

Embodiment 2

[0035] Example 2 Treat raw material B in Table 1, use the catalyst in Table 2 in the hydrotreating reaction zone, use the catalyst in Table 3 in the hydroisomerization reaction zone, and use the catalyst developed and produced by Fushun Petrochemical Research Institute for hydrogenation and supplementary hydrofining The properties of the FV-10 catalyst are shown in Table 5, and the results obtained are specifically shown in Table 6. The hydrogenation treatment and hydrogenation supplementary refining catalyst are subjected to hydrogenation treatment and supplementary refining reaction after being vulcanized according to the conventional method, and the hydroisomerization catalyst is subjected to the hydroisomerization reaction after being reduced according to the conventional method.

[0036] The processing condition and the result of table 4 embodiment 1

[0037] Hydrotreating process conditions

[0038] Aromatic content, wt%

[0039] Main composition and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com