Method for preparing high-purity propane, iso-butane and n-butane

A technology of isobutane and n-butane, which is applied in the field of preparation of high-purity propane, isobutane and n-butane, can solve the problems of high olefin content and large hydrogen consumption, and achieve strong raw material adaptability and high processing capacity Large, consistent quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment specifically set forth the embodiment of the present invention

[0035] 1. Raw material preparation

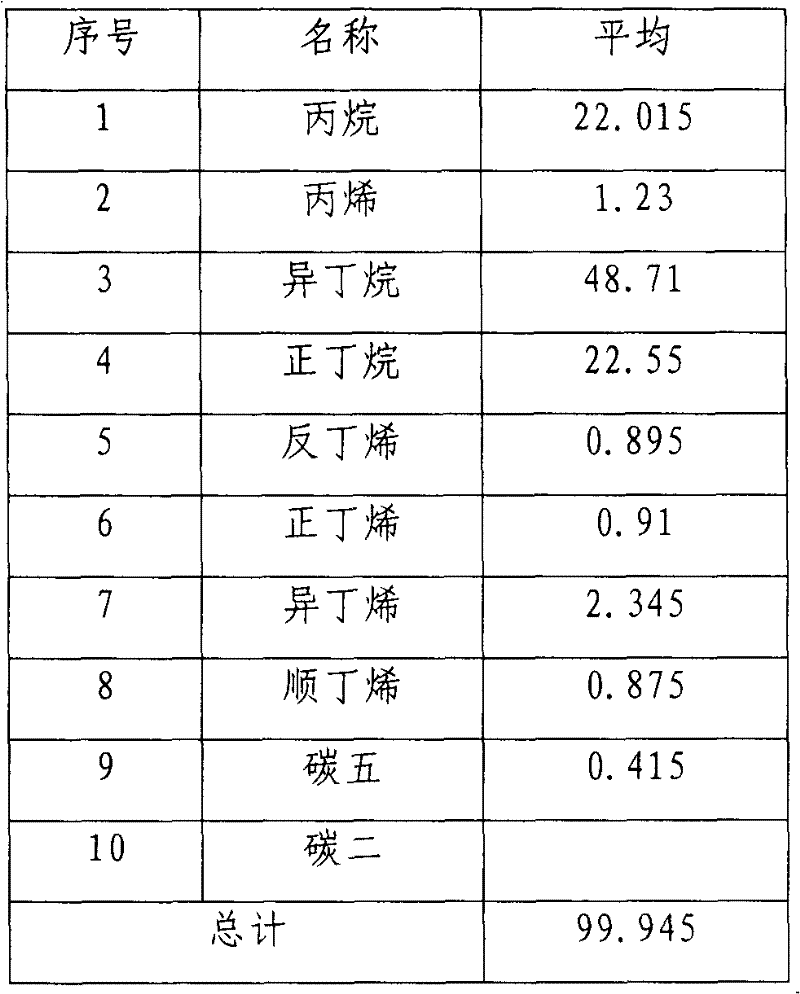

[0036] ① After propylene extraction, etherification, and aromatization, the remaining mixed C4 is used as hydrogenation feedstock. The composition of an aromatization tail gas is shown in Table 1, in which the mass content of total olefins is 6.255%, and the mass content of total alkanes is 93.275%. , carbon five mass content 0.415%;

[0037] Table 1

[0038]

[0039] ②Hydrogen, cylinder hydrogen, purity ≮99.0wt%

[0040] ③Hydrogenation device and process

[0041] ④Hydrogenation operating conditions: The total filling volume of hydrogenation catalyst is 2.0L, including 0.25L of auxiliary agent, 1.75L of main agent, and the volume space velocity of main agent is 8.0h -1 , Catalyst inlet temperature 185°C, hydrogen oil ratio 500v / v, inlet pressure 1.6MPa

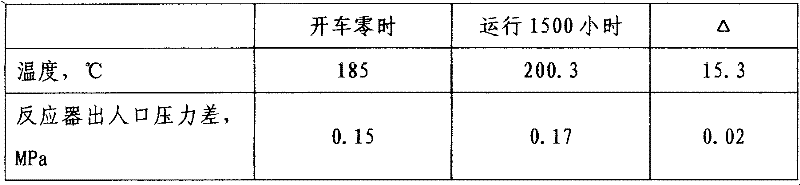

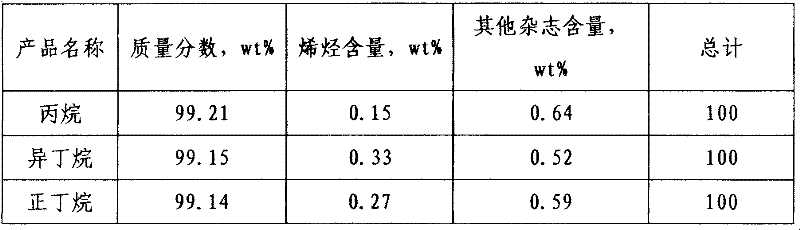

[0042] ⑤The result of continuous operation for 1500h

[0043] (1) Chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com