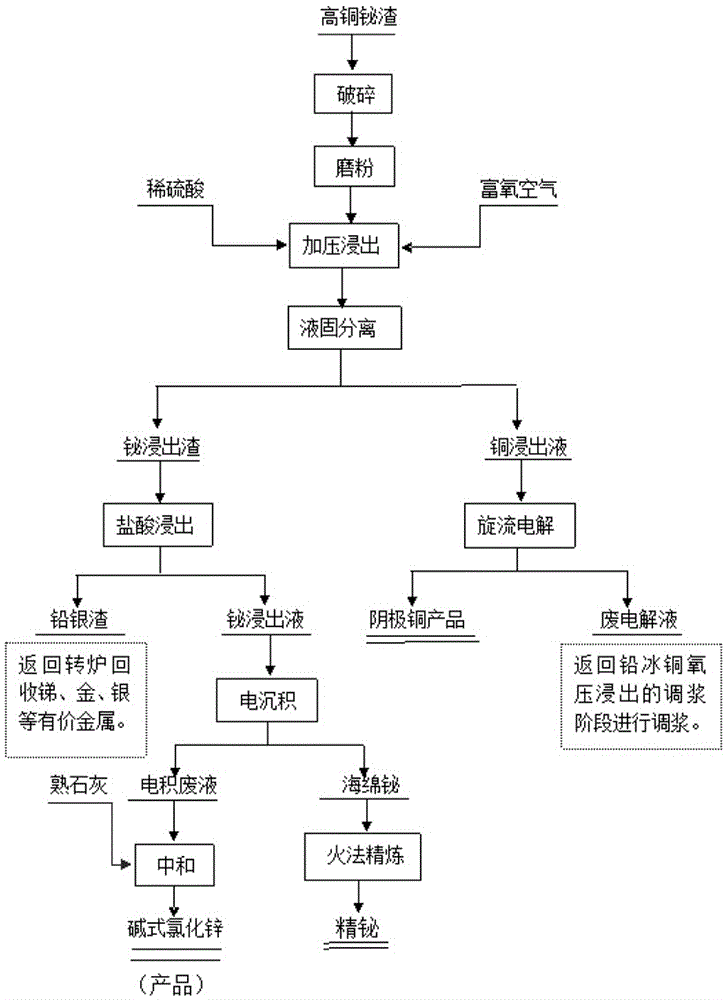

Method used for selective high-efficiency extraction of copper and bismuth from high-copper bismuth slag

A selective, bismuth slag technology, applied in the direction of improving process efficiency, can solve the problems of complex process flow, high production cost, long production cycle, etc., and achieve the effect of low operating cost, convenient operation, and high degree of comprehensive recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. Take 500g of high-copper bismuth slag (Bi 32.49%; Cu 16.56%; Pb 30.37%; Sb 1.14%; Ag 9.32 kg / t; Au1.98g / t) crushing ball mill until the particle size is -100 mesh, and 100 g / t L of sulfuric acid solution is mixed and poured into an autoclave for oxidation leaching to remove copper. Control technical conditions: liquid-solid volume mass ratio is 5:1 L / kg, leaching time is 2h, oxygen pressure is 0.8MPa, leaching temperature is controlled at 85 ±3°C; after leaching and filtering, the obtained filter residue composition was analyzed as follows: Bi 36.08%, Cu0.32%, Pb33.12%, Sb 1.82%, Ag9.97 kg / t, Au 2.32 g / t, residue The rate is 90.68%, and the copper leaching rate is 98.25%;

[0027] b. The volume of the leaching solution in step a is 5000 ml, containing 32.36 g / L of Cu, and the copper is sent to the copper swirl electrolysis to extract copper; the voltage of the copper swirl electrolytic cell is 2.5V, and the current density is 600A / m 2 , the electrolysis time is 2h, ...

Embodiment 2

[0031] a. Take 500g of high-copper bismuth slag (Bi 31.76%; Cu 15.42%; Pb 30.99%; Sb 1.18%; Ag 6.17 kg / t; Au1.71g / t) crushing ball mill until the particle size is -100 mesh, and 100 g / t L of sulfuric acid solution is mixed and poured into an autoclave for oxidative leaching to remove copper. Control technical conditions: liquid-solid volume mass ratio is 5:1 L / kg, leaching time is 2h, oxygen pressure is 0.6MPa, leaching temperature is controlled at 80 ±3°C; after leaching and filtering, the obtained filter residue composition was analyzed as follows: Bi 35.84%, Cu0.45%, Pb34.01%, Sb 1.45%, Ag7.80 kg / t, Au 2.03 g / t, residue The rate is 89.73%, and the copper leaching rate is 97.74%;

[0032] b. The volume of the leaching solution in step a is 5000 ml, containing Cu 30.17 g / L, and the copper is sent to the copper swirl electrolysis to extract copper; the voltage of the copper swirl electrolytic cell is 2.5V, and the current density is 600A / m 2 , the electrolysis time is 2h, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com