Method for regenerating high-purity nickel sulfate from nickel-based alloy waste material

A technology of nickel-based alloy waste and nickel sulfate, applied in the direction of improving process efficiency, etc., can solve the problem of no report on the regeneration of high-purity nickel sulfate, and achieve the effects of strong raw material adaptability, environmental friendliness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

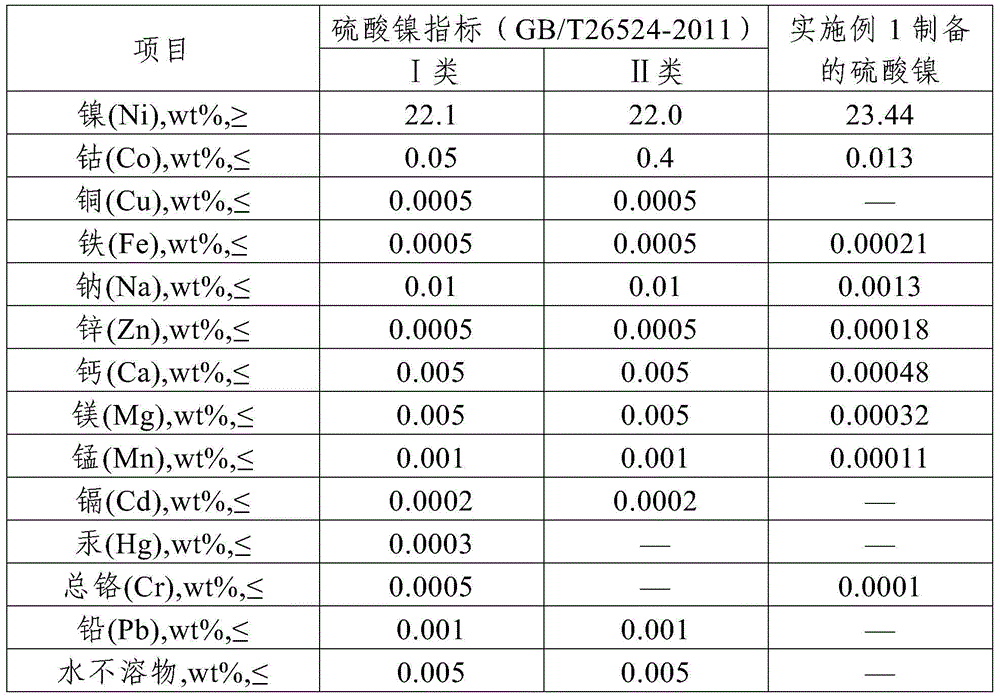

Embodiment 1

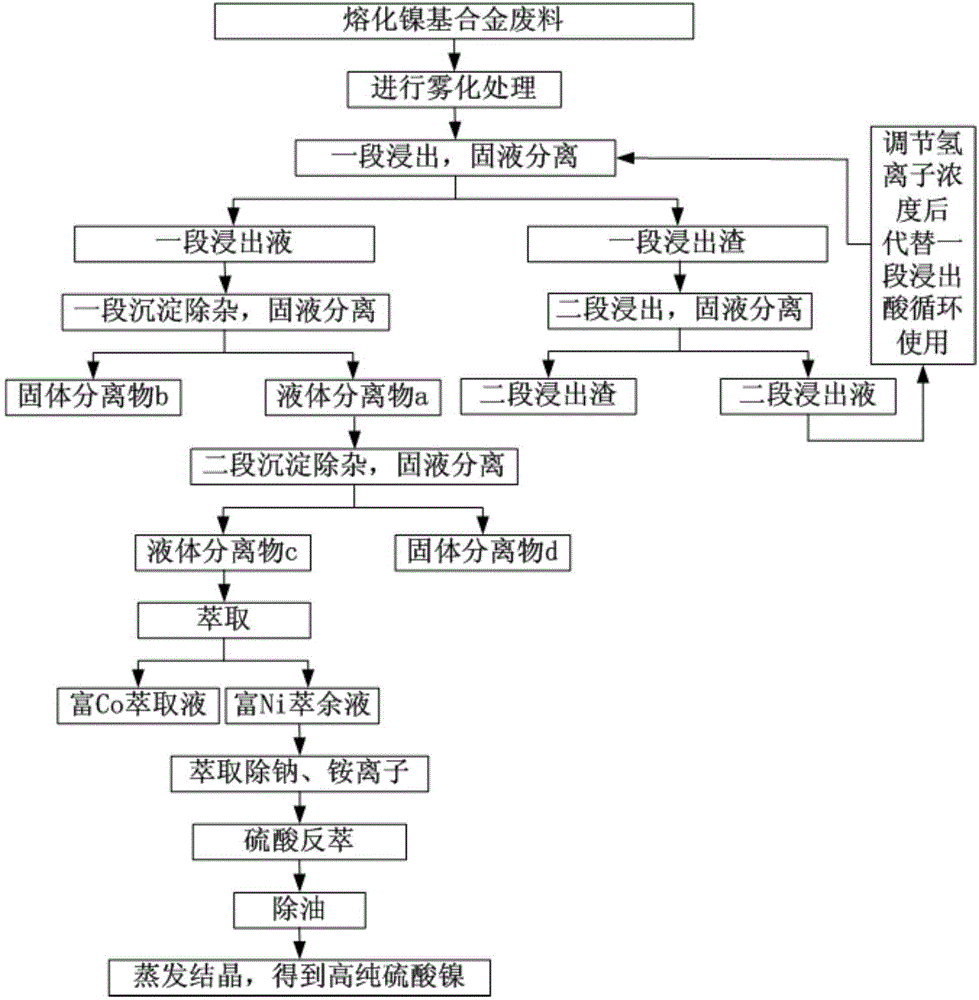

[0039] to combine figure 1 , the present embodiment regenerates the method for high-purity nickel sulfate from nickel-base alloy waste material and comprises the following steps:

[0040] Step 1. Melting the nickel-based alloy scrap into a liquid state in a high-frequency induction melting furnace to obtain an alloy solution; after testing, the nickel-based alloy scrap contains 62.34wt% of Ni and 8.67wt% of Co;

[0041] Step 2, using water atomization to atomize the alloy solution described in step 1 to obtain alloy powder;

[0042] Step 3, place the alloy powder in step 2 in a leaching acid for a leaching treatment, obtain a leaching solution and a leaching slag after solid-liquid separation; the concentration of hydrogen ions in the leaching acid is 2mol / L, the The volume V of the leaching acid in the first stage 1 Meet: V 1 =5m 1 , where m 1 is the mass of alloy powder, m 1 The unit is g, V 1 The unit is mL, the temperature of the first-stage leaching treatment is 75°C...

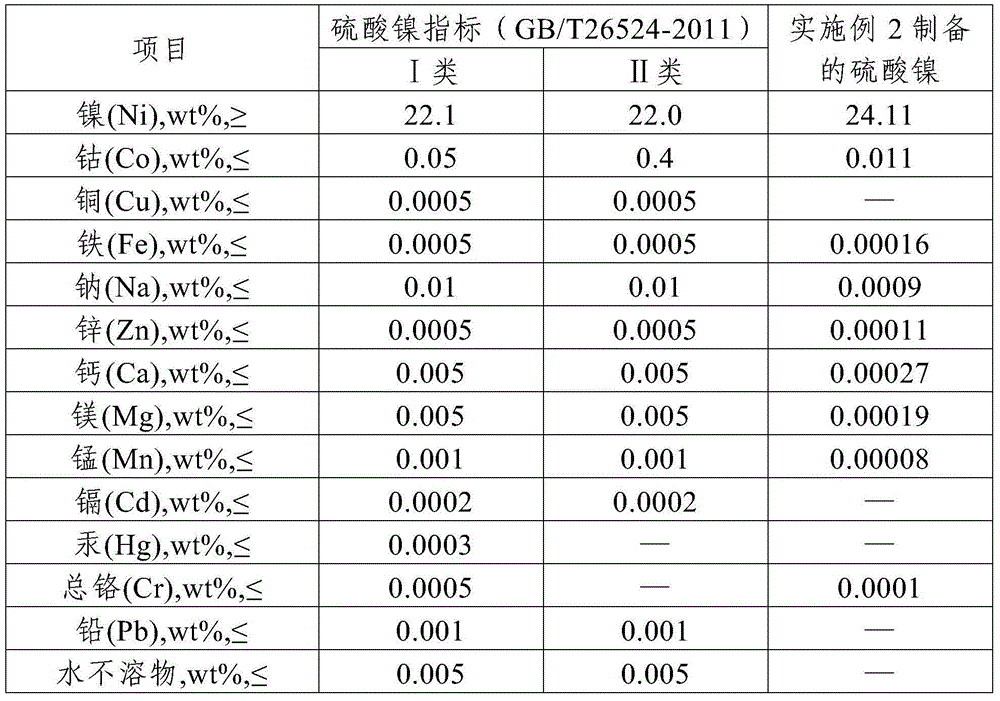

Embodiment 2

[0061] combine figure 1 , the present embodiment regenerates the method for high-purity nickel sulfate from nickel-base alloy waste material and comprises the following steps:

[0062] Step 1. Melting the nickel-based alloy scrap into a liquid state in an electric arc furnace to obtain an alloy solution; after testing, the nickel-based alloy scrap contains 58.31wt% of Ni and 10.24wt% of Co;

[0063] Step 2, using a gas atomization method to atomize the alloy liquid described in step 1 to obtain alloy powder;

[0064] Step 3, placing the alloy powder described in step 2 in a stage of leaching acid for a stage of leaching treatment, and obtaining a stage of leachate and a stage of leaching slag after solid-liquid separation; the concentration of hydrogen ions in the stage of leaching acid is 4mol / L, the resulting The volume V of the leaching acid in the first stage 1 Meet: V 1 =6m 1 , where m 1 is the mass of alloy powder, m 1 The unit is g, V 1 The unit is mL, the temper...

Embodiment 3

[0083] combine figure 1 , the present embodiment regenerates the method for high-purity nickel sulfate from nickel-base alloy waste material and comprises the following steps:

[0084] Step 1. Melting the nickel-based alloy scrap into a liquid state in an intermediate frequency induction melting furnace to obtain an alloy liquid; after testing, the nickel-based alloy scrap contains 50.21wt% of Ni and 9.77wt% of Co;

[0085] Step 2, using water atomization to atomize the alloy solution described in step 1 to obtain alloy powder;

[0086] Step 3, place the alloy powder in step 2 in a leaching acid for a leaching treatment, obtain a leaching solution and a leaching slag after solid-liquid separation; the concentration of hydrogen ions in the leaching acid is 5mol / L, and the The volume V of the leaching acid in the first stage 1 Meet: V 1 = 4m 1 , where m 1 is the mass of alloy powder, m 1 The unit is g, V 1 The unit is mL, the temperature of the first-stage leaching treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com