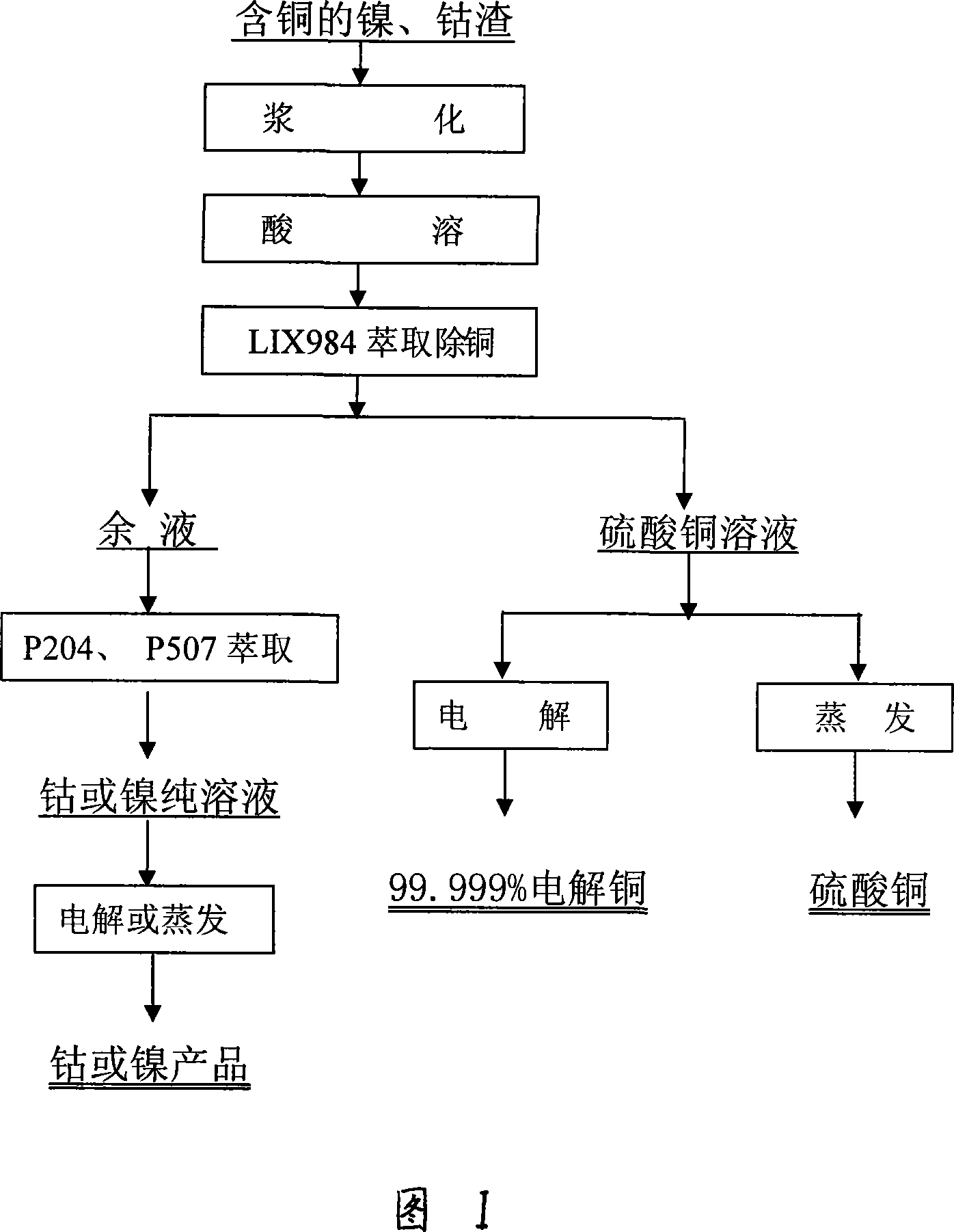

Method for separating copper from nickel and cobalt solution

A nickel-cobalt, solution technology, applied in the direction of improving process efficiency, can solve the problems of high material consumption, high processing cost, high cost of copper removal process, and achieve less raw material and energy consumption, stable production process control, and comprehensive utilization effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using LIX984 extractant, see Table 1 for the chemical composition of the copper-nickel-cobalt feed solution.

[0026] Table 1 LIX Extraction and removal of chemical components of copper feed liquid in nickel and cobalt solutions

[0027] Chemical composition (g / l)

[0028] The organic ratio is 25%; the organic diluent is No. 260 solvent oil; the copper in the feed solution is removed by 2-stage countercurrent extraction; the loaded organic phase is washed by 2-stage dilute acid solution; the copper in the organic is loaded by 3-stage circulation back extraction; The concentration of the loaded organic dilute sulfuric acid is 12g / l; the sulfuric acid concentration of copper in the back extraction loaded organic is 180g / l; LIX The temperature in the process of extracting and removing copper from the nickel-cobalt solution is controlled at 20°C.

[0029] Table 2 LIX Chemical composition of residual liquid after extracting copper from nickel and cobalt ...

Embodiment 2

[0037] Using LIX984 extractant, the chemical composition of the copper-nickel-cobalt-containing liquid is shown in Table 4.

[0038] Table 4 LIX Extraction and removal of chemical components of copper feed liquid in nickel and cobalt solutions

[0039] Chemical composition (g / l)

[0040] The organic ratio is 20%; the organic diluent is No. 260 solvent oil; the copper in the feed liquid is removed by 3-stage countercurrent extraction; the loaded organic phase is washed by a 1-stage dilute acid solution; The concentration of the loaded organic dilute sulfuric acid is 14g / l; the sulfuric acid concentration of copper in the back extraction loaded organic is 179.56g / l; LIX The temperature in the process of extracting and removing copper from the nickel-cobalt solution is controlled at 20°C.

[0041] Table 5 LIX Chemical composition of residual liquid after extracting copper from nickel and cobalt solution

[0042] Chemical composition (g / l)

[0043...

Embodiment 3

[0049] Using LIX984 extractant, see Table 7 for the chemical composition of the copper-nickel-cobalt feed solution.

[0050] Table 7 LIX Extraction and removal of chemical components of copper feed liquid in nickel and cobalt solutions

[0051] Chemical composition (g / l)

[0052] The organic ratio is 25%; the organic diluent is No. 260 solvent oil; the copper in the feed liquid is removed by 2-stage countercurrent extraction; the loaded organic phase is washed by a 1-stage dilute acid solution; The concentration of loaded organic dilute sulfuric acid is 14g / l; the sulfuric acid concentration of back extraction loaded organic copper is 181.89g / l; LIX The temperature in the process of extracting and removing copper from the nickel-cobalt solution is controlled at 20°C.

[0053] Table 8 LIX Chemical composition of residual liquid after extracting copper from nickel and cobalt solution

[0054] Chemical composition (g / l)

[0055] The raffinate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com