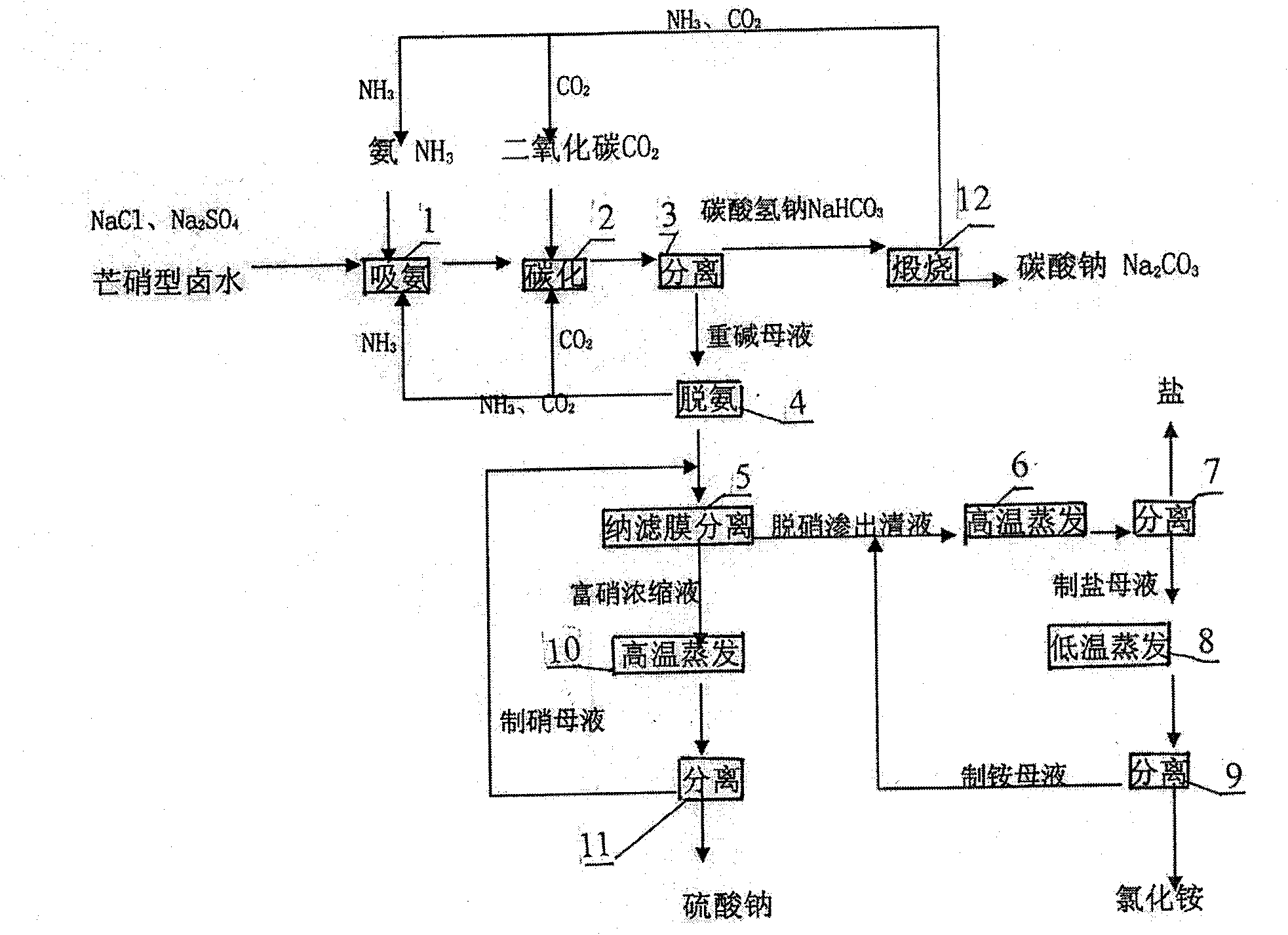

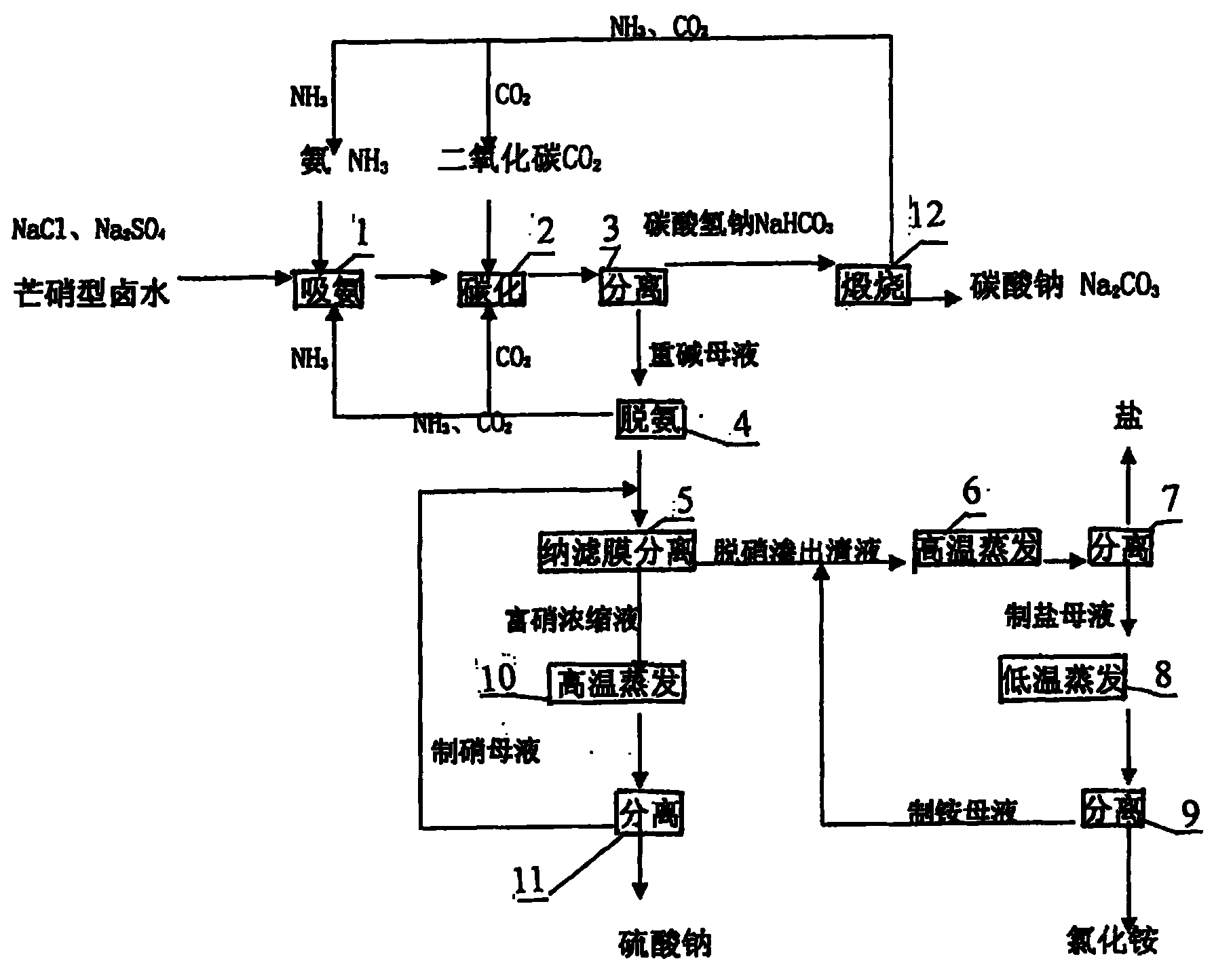

Process for producing mirabilite type bittern, sodium carbonate, sodium chloride, sodium sulfate and ammonium chloride

A technology of sodium chloride and sodium sulfate, applied in the directions of ammonium halide, carbonate preparation, alkali metal chloride, etc., can solve the problems of high cost of raw materials, waste of resources, environmental pollution, etc., and achieve high quality of main and by-products and high production cost. Low, the effect of strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 100m 3 NaCl-Na 2 SO 4 -H 2 O system Glauber's salt brine (NaCl 300g / l, NaCl 2 SO 4 20g / l) and ammonia (NH 3 ), carbon dioxide (CO 2 ) as a raw material for metathesis reaction (reaction temperature 40°C) to separate and obtain 43.45 tons of solid sodium bicarbonate and containing ammonium chloride, sodium sulfate and sodium chloride and a small amount of ammonium bicarbonate (NH 4 HCO 3 ), ammonium carbonate ((NH 4 ) 2 CO 3 ) heavy alkali mother liquor 100m 3 (NaCl 71g / l, NaCl 2 SO4 20g / l, NH 4 Cl 179g / l, a small amount of NH 4 HCO 3 and (NH 4 ) 2 CO 3 ); heavy alkali mother liquor preheating high temperature (temperature 100 ℃) removes ammonium bicarbonate (NH 4 HCO 3 ), ammonium carbonate ((NH 4 ) 2 CO 3 ) to obtain ammonium chloride (NH 4 Cl 179g / l, Na 2 SO 4 20g / l, NaCl 71g / l) deamination mother liquor 100m 3 ; Deamination mother liquor and circulating nitrate mother liquor are separated by nanofiltration membrane to obtain a small ...

Embodiment 2

[0029] Take 100m 3 NaCl-Na 2 SO 4 -H 2 O system Glauber's salt brine (NaCl 270g / l, NaCl 2 SO 4 18g / l) and ammonia (NH 3 ), carbon dioxide (CO 2 ) as a raw material for metathesis reaction (reaction temperature 40°C) to separate and obtain 39.11 tons of solid sodium bicarbonate and containing ammonium chloride, sodium sulfate and sodium chloride and a small amount of ammonium bicarbonate (NH 4 HCO 3 ), ammonium carbonate ((NH 4 ) 2 CO 3 ) heavy alkali mother liquor 100m 3 (NaCl 72g / l, NaCl 2 SO 4 18g / l, NH 4 Cl 180g / l, a small amount of NH 4 HCO 3 and (NH 4 ) 2 CO 3 ); heavy alkali mother liquor preheating high temperature (temperature 100 ℃) removes ammonium bicarbonate (NH 4 HCO 3 ), ammonium carbonate ((NH 4 ) 2 CO 3 ) to obtain ammonium chloride (NH 4 Cl 180g / l, Na 2 SO 4 18g / l, NaCl 72g / l) deamination mother liquor 100m 3 ; Deamination mother liquor and circulating nitrate mother liquor are separated by nanofiltration membrane to obtain a smal...

Embodiment 3

[0031] Take 100m 3 NaCl-Na 2 SO 4 -H 2 O system Glauber's salt brine (NaCl 330g / l, Na 2 SO 4 22g / l) and ammonia (NH 3 ), carbon dioxide (CO 2 ) as a raw material for metathesis reaction (reaction temperature 40°C) to separate and obtain 47.80 tons of solid sodium bicarbonate and contain ammonium chloride, sodium sulfate and sodium chloride and a small amount of ammonium bicarbonate (NH 4 HCO 3 ), ammonium carbonate ((NH 4 ) 2 CO 3 ) heavy alkali mother liquor 100m 3 (NaCl 70g / l, NaCl 2 SO 4 22g / l, NH 4 Cl 180g / l, a small amount of NH 4 HCO 3 and (NH 4 ) 2 CO 3 ); heavy alkali mother liquor preheating high temperature (temperature 100 ℃) removes ammonium bicarbonate (NH 4 HCO 3 ), ammonium carbonate ((NH 4 ) 2 CO 3 ) to obtain ammonium chloride (NH 4 Cl 180g / l, Na 2 SO 4 22g / l, NaCl 70g / l) deamination mother liquor 100m 3 ; Deamination mother liquor and circulating nitrate mother liquor are separated by nanofiltration membrane to obtain a small amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com