Method for preparing sodium stannate from stannic oxide and sodium salt in reduction roasting manner

A technology of tin dioxide and sodium stannate, applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve the problems of energy and material waste, low melting point of metal tin, long reaction time, etc., and achieve cost savings, tin The effect of high conversion rate and strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

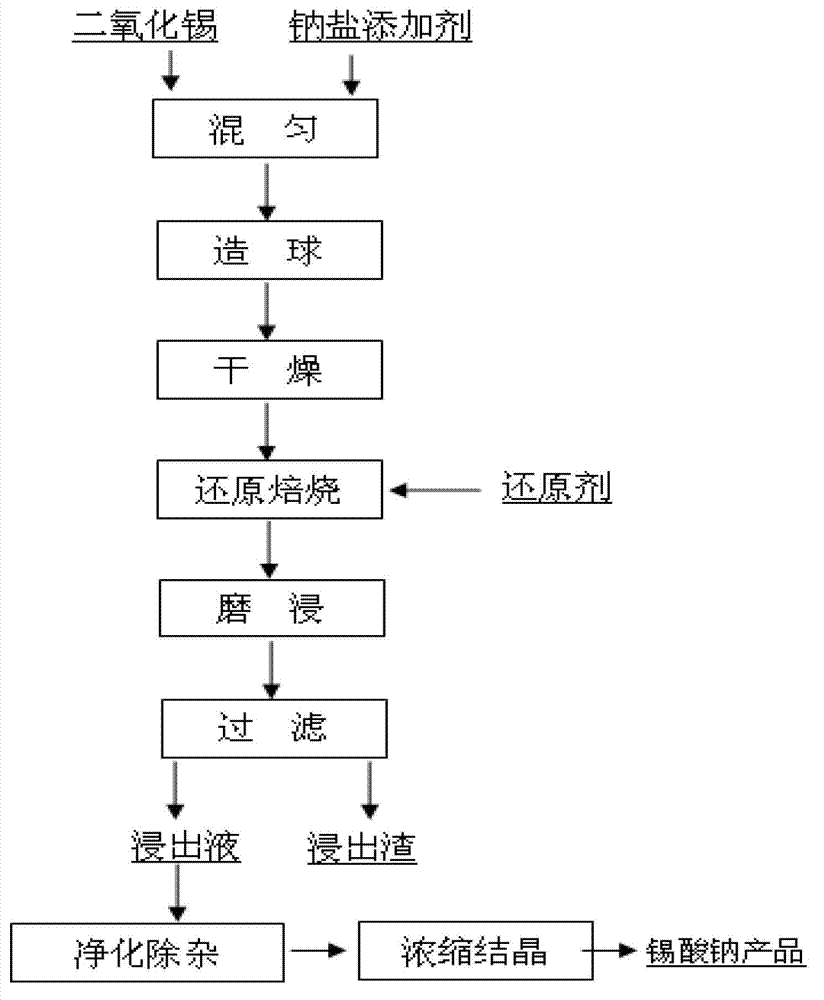

Method used

Image

Examples

Embodiment 1

[0029] Chemically pure tin dioxide (SnO 2 Content is 99.15%) as raw material. Mix finely ground tin dioxide and sodium salt additives (among them: 90% by mass of sodium carbonate and 10% by mass of sodium humate) at a mass ratio of 1:0.8; After pelleting and drying, put it into a static muffle furnace for heating and roasting, using coke powder as the reducing agent, the roasting temperature is 800°C, and the roasting time is 90 minutes; Concentrate crystallization and other treatment to obtain sodium stannate product. The conversion rate of Sn was 79.8%.

Embodiment 2

[0031] Cassiterite concentrate (SnO 2 Content is 88.2%) as raw material. Mix finely ground tin dioxide and sodium salt additives (among them: 92% by mass of sodium carbonate and 8% by mass of sodium humate) at a mass ratio of 1:1; After the briquetting is dried, put it into a simulated ring-shaped rotary hearth furnace for heating and roasting, using coke powder as the reducing agent, the roasting temperature is 850°C, and the roasting time is 75 minutes; Miscellaneous, concentrated crystallization and other treatments to obtain sodium stannate product. The conversion rate of Sn was 84.3%.

Embodiment 3

[0033] Cassiterite concentrate (SnO 2 Content is 72.5%) as raw material. Mix finely ground tin dioxide and sodium salt additives (among them: 93% by mass of sodium carbonate and 7% by mass of sodium humate) at a mass ratio of 1:1.25; After pelleting and drying, put it into a simulated tunnel kiln device for heating and roasting, using coke powder as the reducing agent, the roasting temperature is 875°C, and the roasting time is 60 minutes; Concentrated crystallization and other treatment to obtain sodium stannate product. The conversion rate of Sn was 86.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com