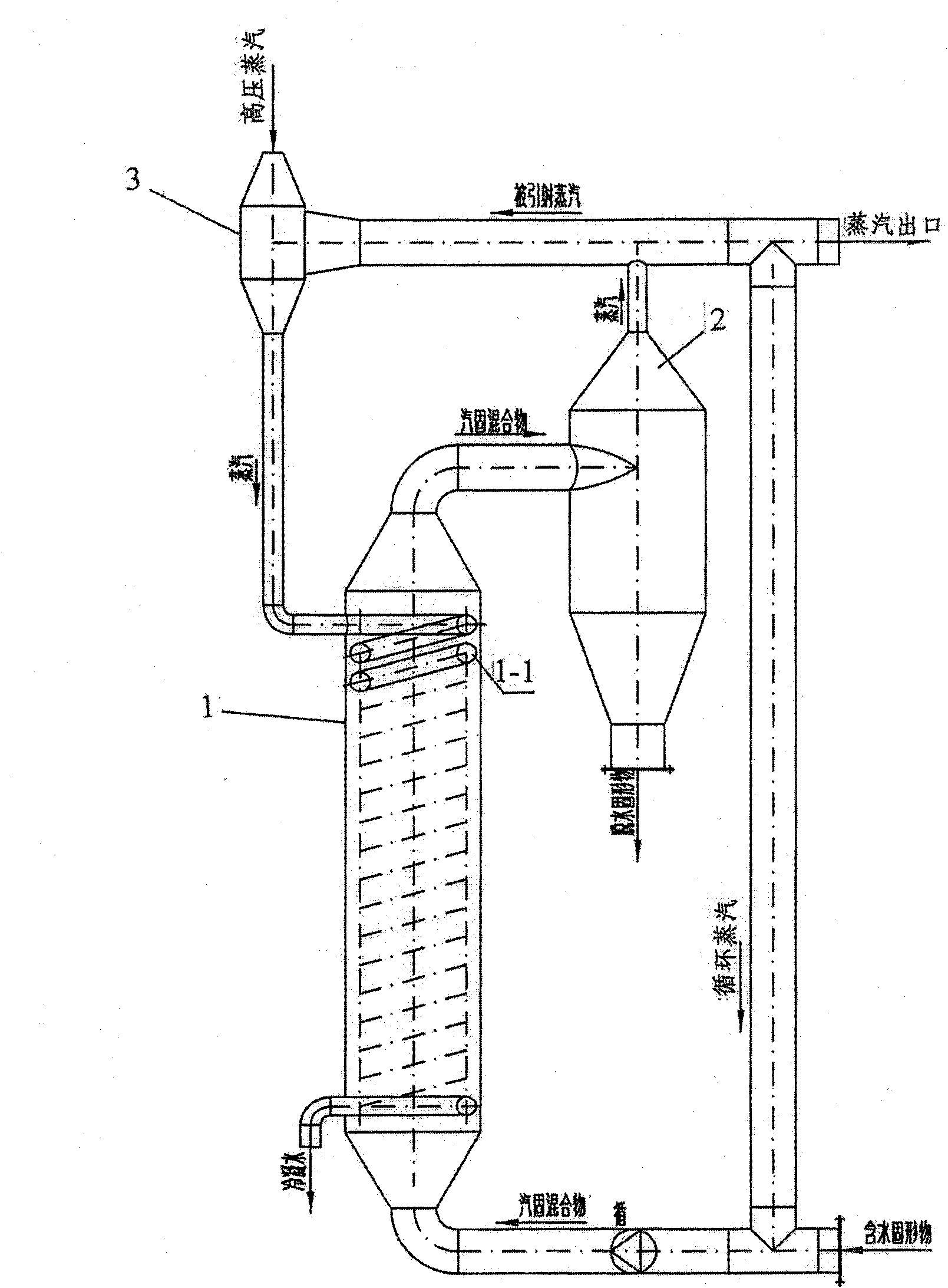

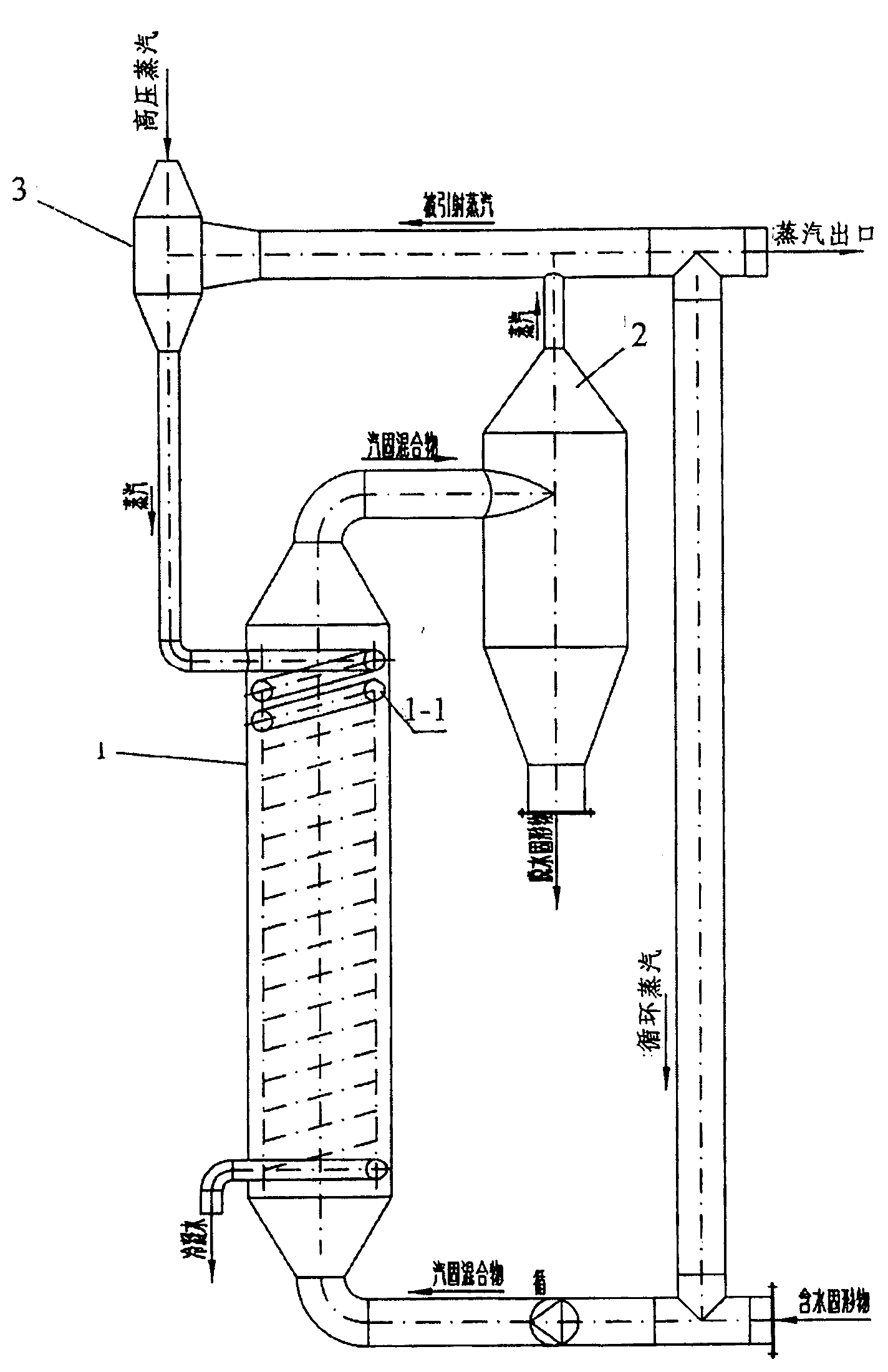

Drying dehydration steam-recycle process and device for solid containing water

A technology for dehydrating steam and solids, which is used in drying solid materials, lighting and heating equipment, heating to dry solid materials, etc. The effect of strong adaptability of raw materials and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: Get 100 tons of papermaking white mud (white mud 30%, water 70%) material and carry out heat transfer evaporative drying dehydration, evaporative drying temperature 110-170 ℃, heating steam (mixed steam) temperature 120-200 ℃, by changing The heater indirectly conducts heat transfer and evaporation with the water-containing solids, and the generated secondary steam and solids are separated from the steam and solids by the body dry dust collector. After dehydration, the solids are used as white mud comprehensive utilization products, and the secondary steam (70 tons / hour) The steam injection pump uses high-pressure working steam (81.67 tons / hour) to inject mixed steam as the heat source for the next cycle heat exchanger to indirect heat transfer and evaporation with water-containing solids, and the other part (46.67 tons / hour) is used as a heat source. .

Embodiment 2

[0013] Embodiment 2: Take 100 tons of inorganic salt (97% of inorganic salt, 3% of water) material and carry out heat transfer evaporation drying dehydration, evaporation drying temperature 110-170 ℃, heating steam (mixed steam) temperature 120-200 ℃, through heat exchange The device indirectly conducts heat transfer and evaporation with the water-containing solid, and the generated secondary steam and solid mixture are separated by steam-solid separation through the body dry dust collector. After dehydration, the solid is used as an inorganic salt product, and the secondary steam (3 tons / hour) is steam injected. The pump uses high-pressure working steam (3.5 tons / hour) to eject the mixed steam as the heat source for the next cycle heat exchanger to transfer heat and evaporate the water-containing solids indirectly, and the other part (2 tons / hour) is used as a heat source.

Embodiment 3

[0014] Example 3: Take 100 tons of washing powder (washing powder 70%, water 30%) for heat transfer, evaporation, drying and dehydration. The device indirectly conducts heat transfer and evaporation with the water-containing solids, and the generated secondary steam and solids are separated by steam-solid separation through the body dry dust collector. After dehydration, the solids are used as washing powder products, and the secondary steam (30 tons / hour) is steam injected. The pump uses high-pressure working steam (35 tons / hour) to extract the mixed steam as the heat source for the next cycle heat exchanger to transfer heat and evaporate the water-containing solids indirectly, and the other part (20 tons / hour) is used as a heat source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com