Crude oil catalytic cracking low carbon olefin and aromatic hydrocarbon preparing method

A catalytic cracking, carbon olefin technology, applied in chemical instruments and methods, catalytic cracking, hydrocarbon cracking to produce hydrocarbons, etc., can solve problems such as the cracking of polycyclic aromatic hydrocarbons, etc., to achieve strong anti-metal pollution, low agent consumption, steam Low dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

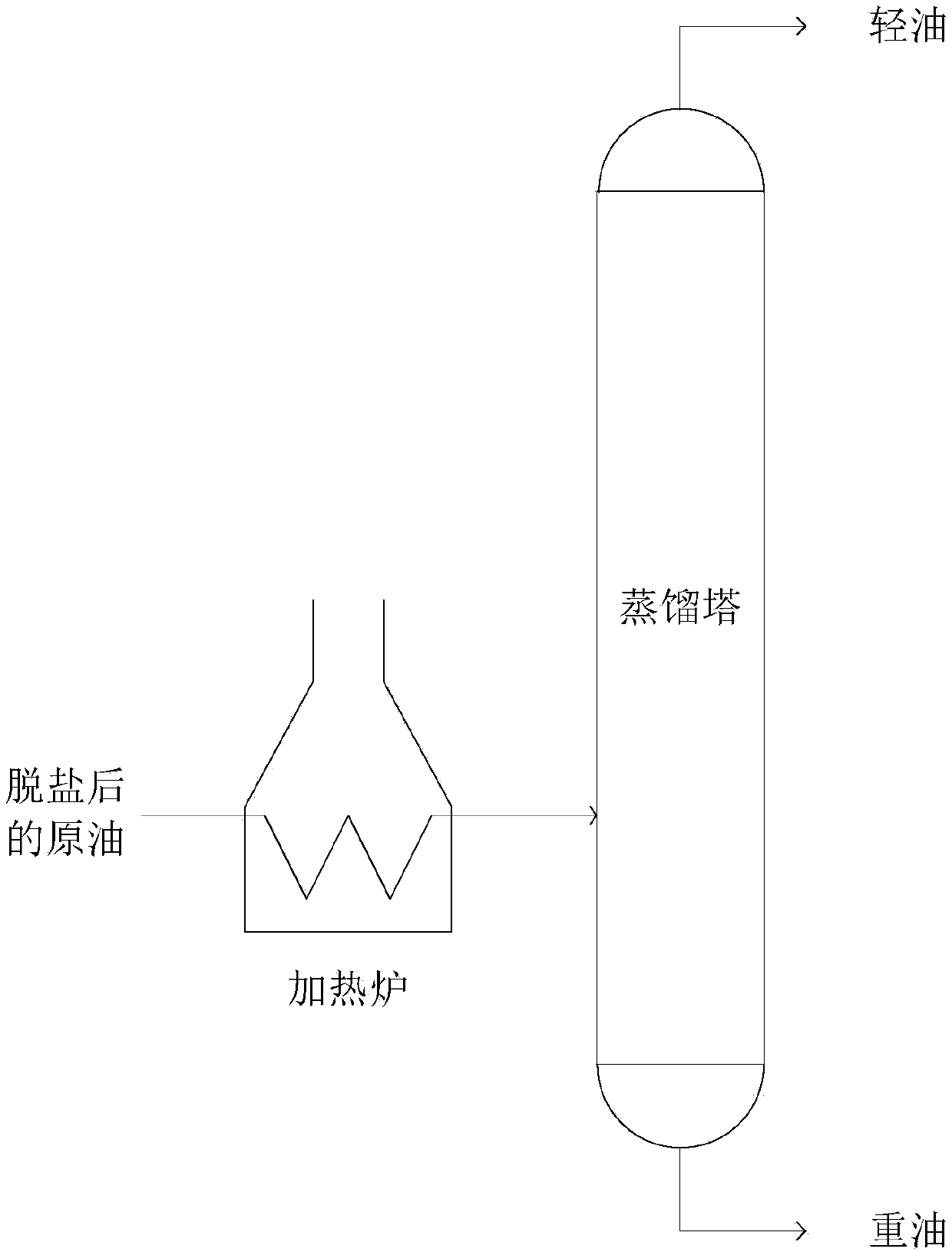

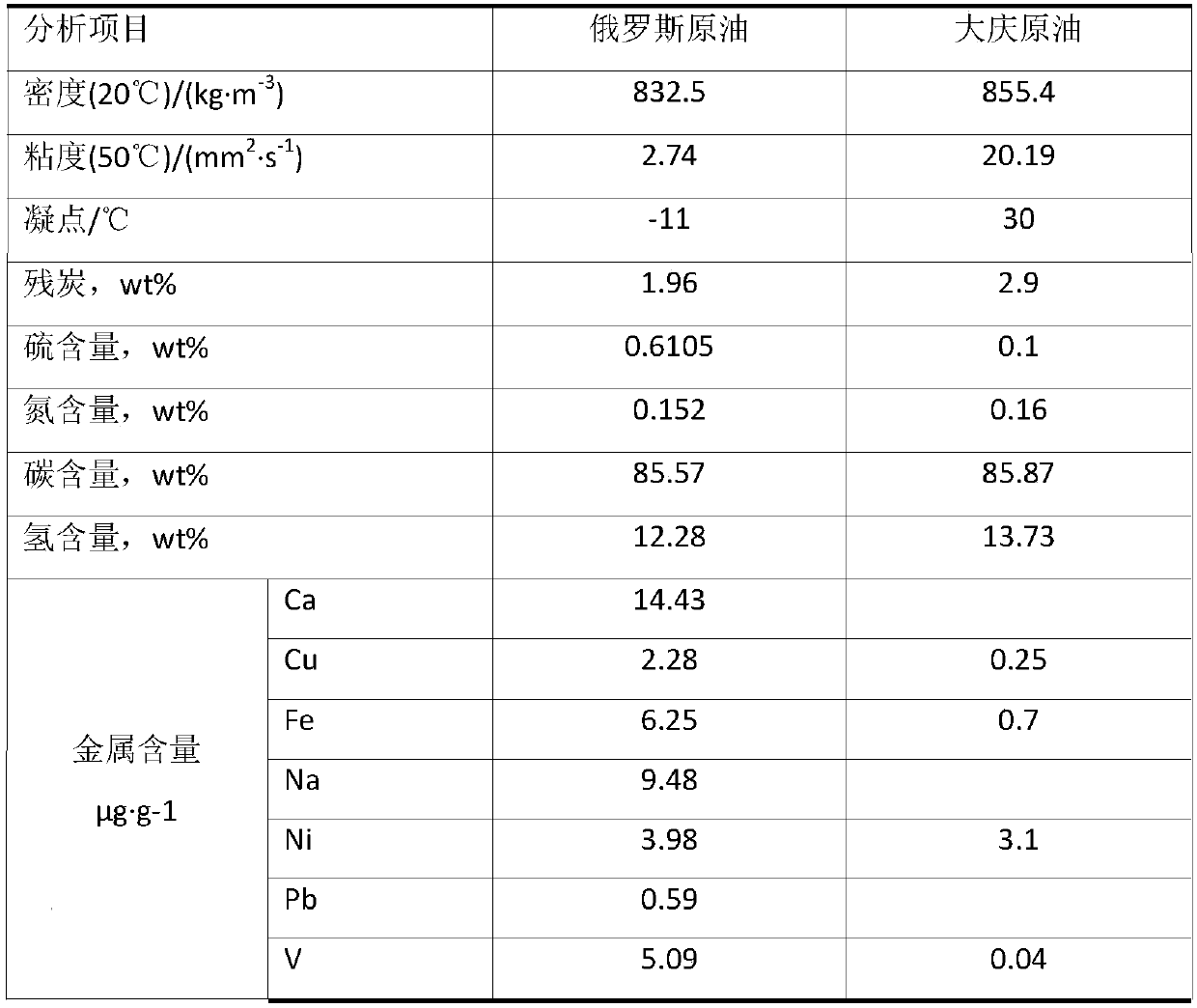

[0028]Reaction experiments were carried out with desalted Russian crude oil and Daqing crude oil respectively. The main properties of the two crude oils are shown in Table 1. Before carrying out the reaction, the light components (naphtha) were extracted by atmospheric distillation respectively, with initial boiling point ~ 200 ° C, wherein the naphtha extracted from Russian crude oil was 23wt%, and the naphtha extracted from Daqing crude oil was 12wt% %.

[0029] Table 1. Main properties of Russian crude oil and Daqing crude oil

[0030]

[0031] The reaction is carried out on a circulating fluidized bed device, the catalyst storage capacity of the reverse regeneration system is 30kg, and the catalyst regeneration temperature is 800°C.

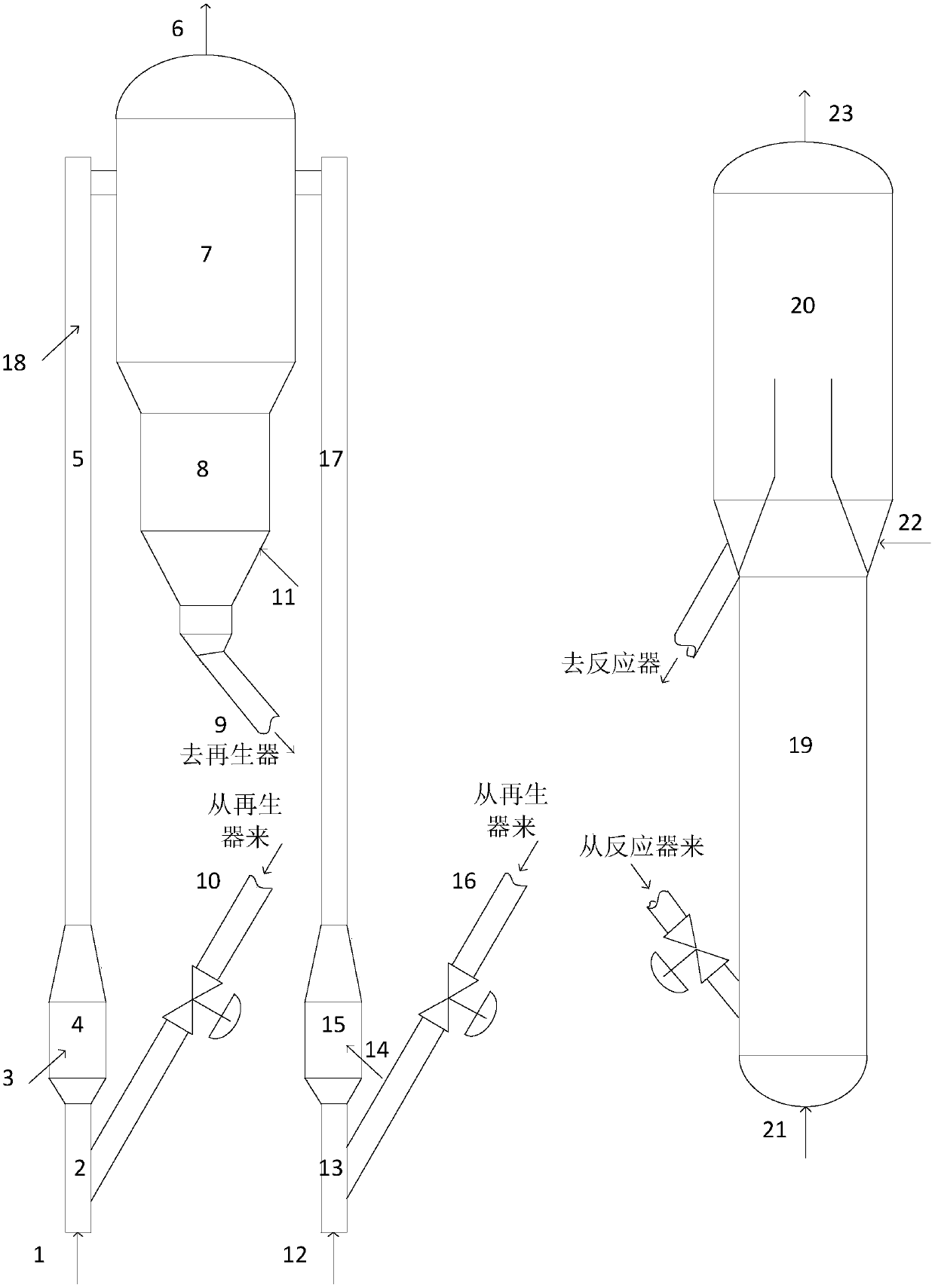

[0032] Attached figure 2 The light and heavy feeds shown are reacted in two reactors with dense phase sections. The operating conditions and reaction product distribution are shown in Table 2. Catalyst oxide composition: SiO 2 / Al 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com