Method of efficiently separating and recovering arsenic, copper and zinc from arsenic-copper-containing smelting smoke dust pickle liquor

A technology of copper smelting and acid leaching solution, which is applied in the field of high-efficiency separation and recovery of arsenic and zinc in acid leaching solution of copper and arsenic-containing copper smelting dust, which can solve the problems of difficult separation, pollution of ecological environment by arsenic-containing hazardous waste residue, and low added value. , to achieve the effect of flexible operation, strong adaptability of raw materials and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

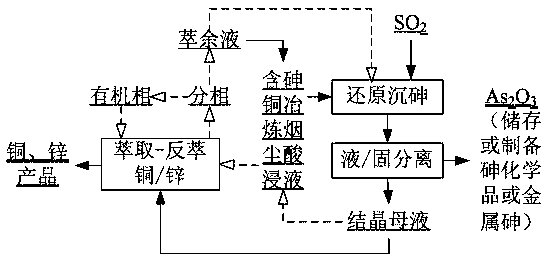

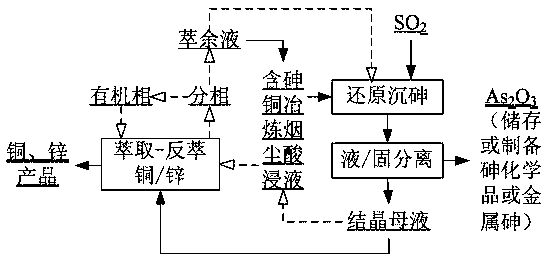

[0029] Such as figure 1 As shown, the method for efficiently separating and recovering arsenic, copper, and zinc from acid leaching solution of arsenic-containing copper smelting dust mainly includes the following steps:

[0030] Step 1. Pour SO into the acid leaching solution of copper smelting dust containing arsenic (8.3g / L copper, 36.4g / L zinc, 120g / L arsenic, pH=1) 2 Reduce precipitation of arsenic, filter to obtain crystals and crystallization mother liquor; pass in SO 2 The specific process of reducing and precipitating arsenic is as follows: at a temperature of 85°C, a flow of 60L / min of SO is introduced into the acid leaching solution of arsenic copper smelting dust 2 Gas, reduce precipitation for 30 minutes, obtain crystals and crystal mother liquor after filtration;

[0031] Step 2. Use organic solvent extraction and stripping to recover copper from the crystallization mother liquor obtained in Step 1 to obtain copper product and copper extraction residue; the extraction ...

Embodiment 2

[0035] Such as figure 1 As shown, the method for efficiently separating and recovering arsenic, copper, and zinc from acid leaching solution of arsenic-containing copper smelting dust mainly includes the following steps:

[0036] Step 1. Pour SO into the acid leaching solution of copper smelting dust containing arsenic (1g / L copper, 5g / L zinc, 15g / L arsenic, pH=3) 2 Reduce precipitation of arsenic, filter to obtain crystals and crystallization mother liquor; pass in SO 2 The specific process of reducing and precipitating arsenic is as follows: at a temperature of 20°C, a flow of 5L / min of SO is introduced into the acid leaching solution of arsenic copper smelting dust 2 Gas, reduce precipitation for 240min, obtain crystals and crystal mother liquor after filtration;

[0037] Step 2. Use organic solvent extraction and stripping to recover copper from the crystallization mother liquor obtained in Step 1 to obtain copper product and copper extraction residue; the extraction process is:...

Embodiment 3

[0041] Such as figure 1 As shown, the method for efficiently separating and recovering arsenic, copper, and zinc from acid leaching solution of arsenic-containing copper smelting dust mainly includes the following steps:

[0042] Step 1. Pour SO into the acid leaching solution of copper smelting dust containing arsenic (50g / L copper, 50g / L zinc, 64g / L arsenic, pH=2) 2 Reduce precipitation of arsenic, filter to obtain crystals and crystallization mother liquor; pass in SO 2 The specific process of reducing and precipitating arsenic is as follows: at a temperature of 50°C, a flow of 30L / min of SO is introduced into the acid leaching solution of arsenic copper smelting dust 2 Gas, reduce precipitation for 120min, obtain crystals and crystal mother liquor after filtration;

[0043] Step 2. Use organic solvent extraction-reverse extraction to recover copper from the crystallization mother liquor obtained in Step 1 to obtain copper product and copper extraction residue; the extraction pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com