Method for producing high-quality fuel oil by heavy oil hydrocracking

A heavy oil hydrogenation and hydrocracking technology, which is applied in the production of high-quality fuel oil and heavy oil hydrocracking to produce high-quality fuel oil, can solve the problems of low product quality and low hydrogenation capacity, and achieve reasonable process and high yield Efficiency and high-quality, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

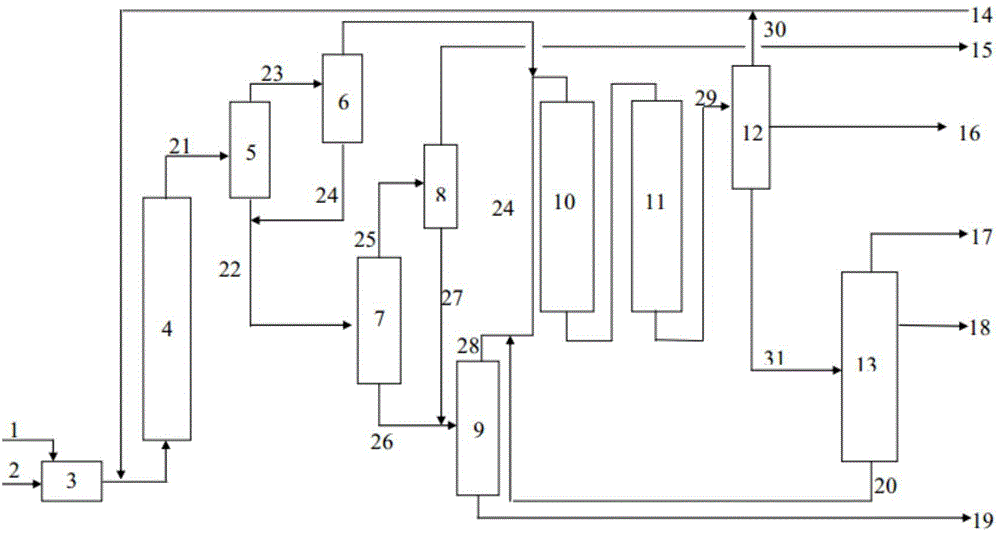

[0024] The method for producing high-quality fuel oil by hydrocracking of heavy oil of the present invention comprises the following steps:

[0025] a) The heavy oil is mixed with the suspended bed hydrocracking catalyst and hydrogen and enters the suspended bed hydrocracking reactor; the operating pressure of the suspended bed hydrocracking reactor is 12-20MPa, the temperature is 400-500°C, and the volume ratio of hydrogen to oil is 500-1500, The amount of catalyst added is 0-3.0%, and the space velocity is 0.3-1.0h -1 ; The suspended bed hydrocracking reactor has no internal components, and the fluid passes through the suspended bed hydrocracking reactor in a plug flow manner. The heavy oil is atmospheric / vacuum residual oil, medium-low temperature coal tar, coker wax oil or heavy heavy oil. The suspended bed hydrocracking is a solid powder catalyst, an oil-soluble catalyst or a water-soluble catalyst used for cracking heavy and inferior oil.

[0026] b) The reactant of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com