Efficient incineration equipment for waste incineration processing

A waste incineration and high-efficiency technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of insufficient waste burning, affecting the effect of waste treatment, and untreated waste gas, so as to achieve safe and convenient use, increase efficiency, The effect of reducing moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

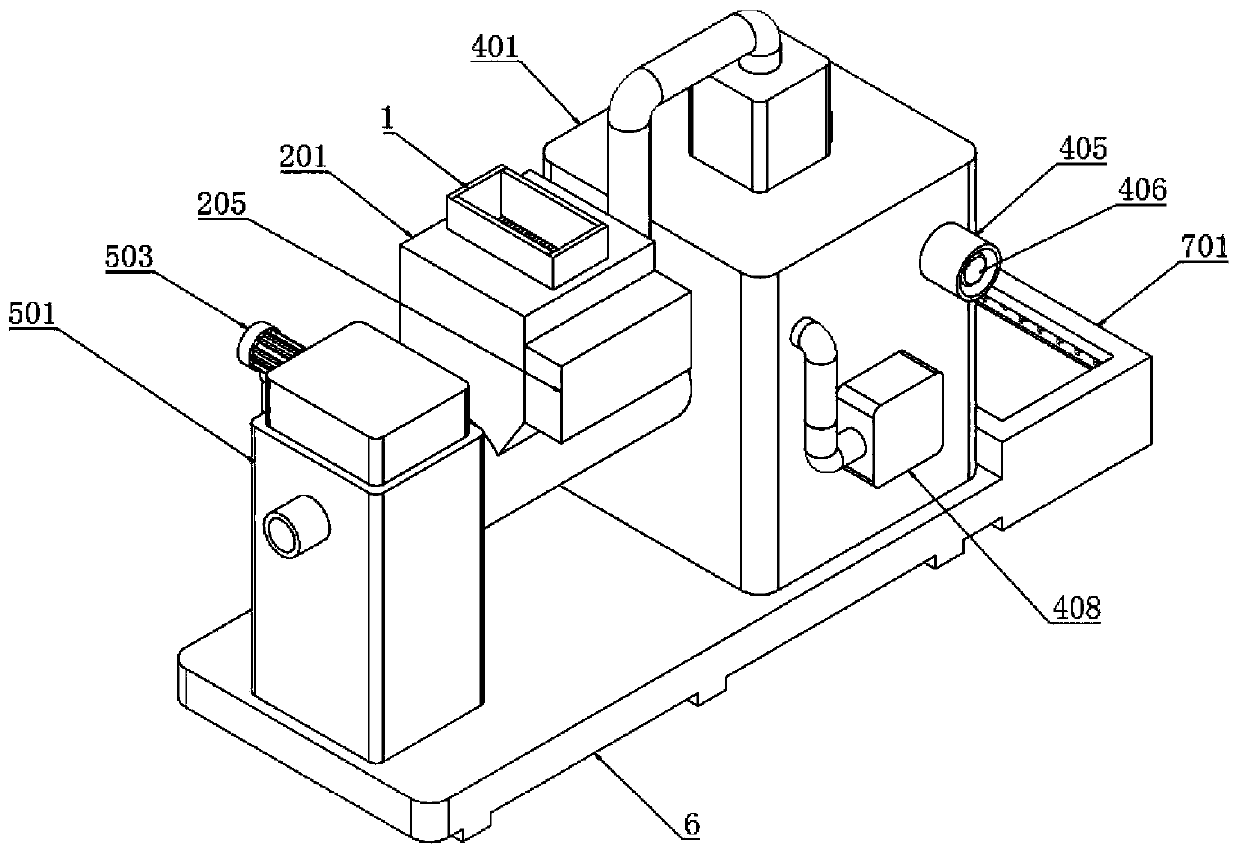

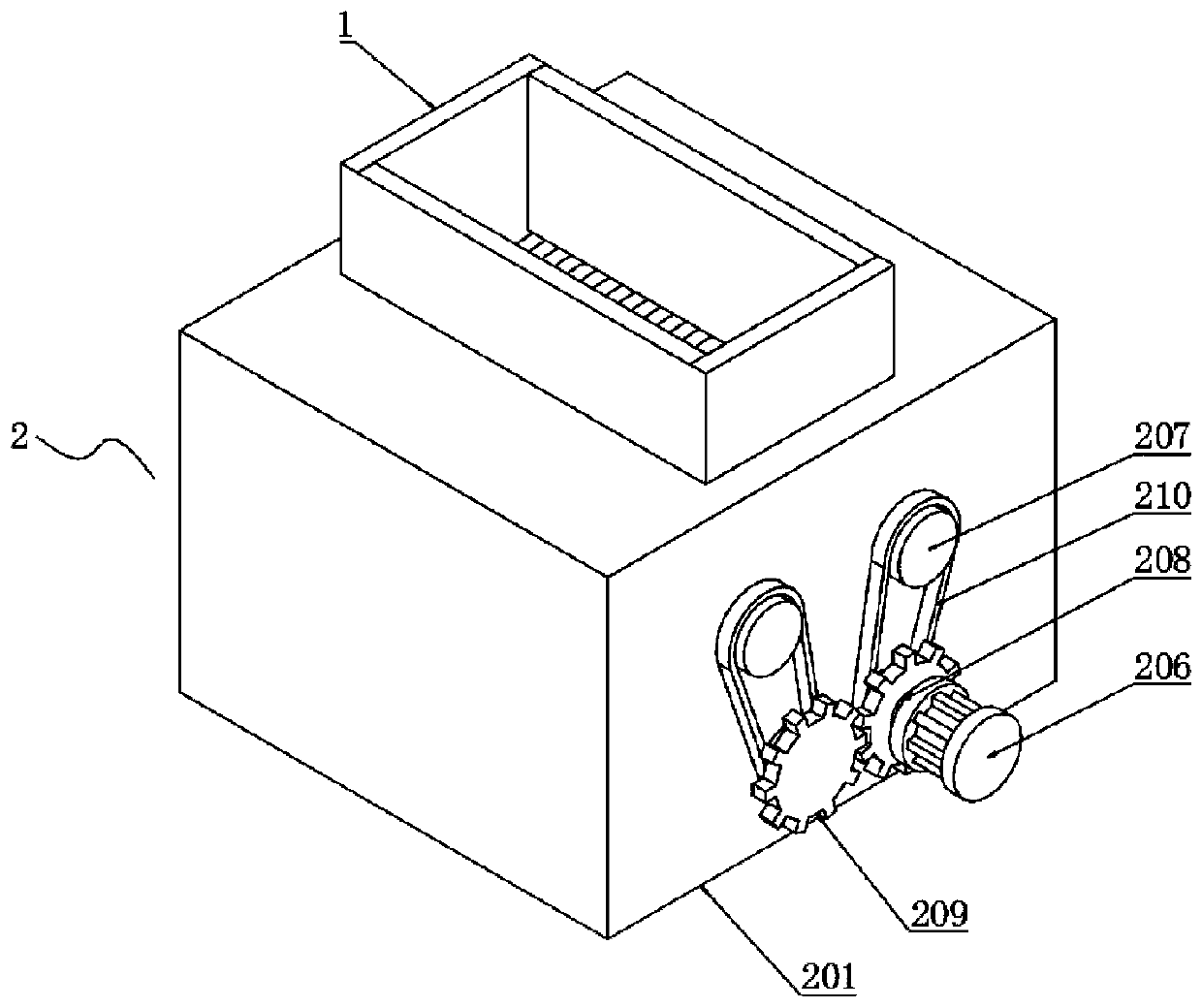

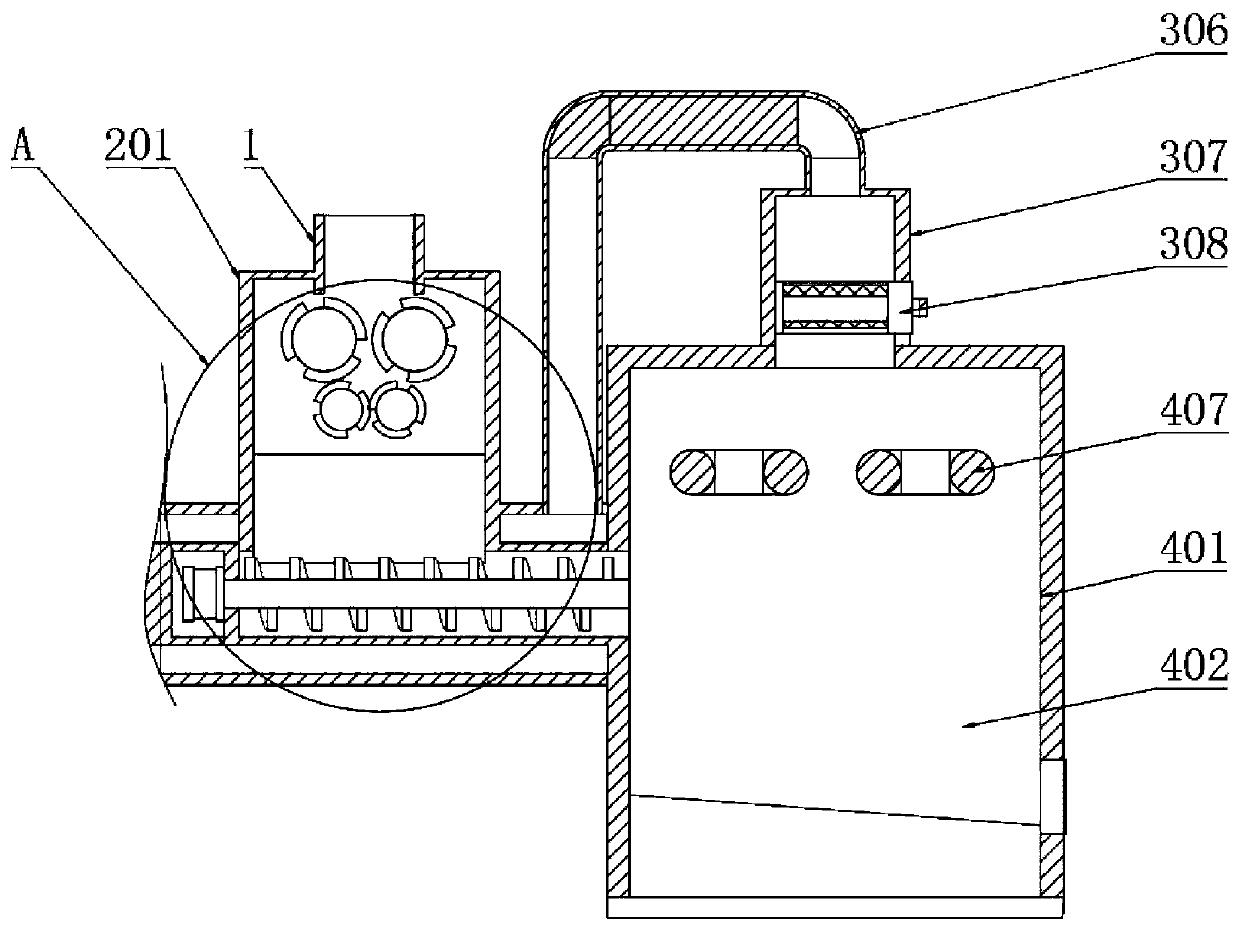

[0049] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a high-efficiency incineration equipment for waste incineration, including a feed channel 1, and a crushing mechanism 2 is fixedly connected to the bottom end of the feed channel 1;

[0050] The crushing mechanism 2 comprises a crushing box 201, a crushing chamber 202, a coarse roller 203, a fine roller 204, a transmission box 205, a rotating motor 206, an upper rotating shaft 207, a lower rotating shaft 208, a gear 209 and a belt 210;

[0051] The bottom end of the feed channel 1 is fixedly connected with a crushing box 201, and the inside of the crushing box 201 is provided with a crushing chamber 202, and the top position of the inner wall of the crushing chamber 202 is symmetrically rotated and connected with a rough roller 203, and the inner wall of the crushing chamber 202 corresponds to the rough roller 203 bottom position symmetrically rotates fine grinding roller 204, cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com