[0002] The existing domestic waste incinerators are all designed for certain components of waste, a certain range of

water content or calorific value and other parameters, so the same type of domestic waste incinerator can only be within the range of its set parameters. If used, if it exceeds the set range, the various indicators of its

combustion will not reach the set indicators, and the combustion effect will not be ideal; however, the

physical composition,

moisture content, calorific value, etc. of domestic waste vary greatly, usually It is difficult to conform to the range set by the incinerator. For example, its physical components include water, paper or

wood waste, vegetable or fruit residues, kitchen waste, fallen leaves and hoeed flowers and plants, ash, etc. Not only are there many types, but also It is difficult to predict the type, because the physical composition,

water content, calorific value, etc. of these components also vary with seasons, climates, regions, etc., and there will be great differences even within the same day, so the to-be-incinerated

Domestic waste is usually difficult to meet the scope of use of the incinerator, that is to say, the existing domestic waste incinerators have a problem with the actual combustion effect of the incinerator because the parameters during use are difficult to meet the setting range of the incinerator. A problem that is worse than its setting effect

[0003] In order to make the actual combustion effect of the incinerator close to the set effect, the existing domestic waste incinerators use the adjustment of the movement frequency of the grate pieces to change the degree of stirring of the grate pieces to the garbage material layer and the height of the material layer, but the adjustment method is in When it is used for garbage whose composition and calorific value fluctuate greatly, it will be difficult to find a

balance point between the

thermal ignition loss rate of the garbage and the load, and it is difficult to make both of them meet the

incineration index: for example, when the garbage When the water content is high and the calorific value is low, the movement frequency of the grate needs to be slowed down in order to ensure its heat

reduction rate, so that the garbage is not completely burned and pushed out of the furnace by the grate; but the movement of the grate is slowed down and the agitation is weakened , will reduce the load of the incinerator, and if the movement of the grate is accelerated, the heat

reduction rate will exceed the standard

Conversely, when burning waste with high calorific value, if the grate movement is accelerated to shorten the

residence time of the material in the furnace, the load of the incinerator will be too high and there is a danger of exceeding the design value, and slowing down the grate speed will prolong the life of the furnace. Unnecessary

residence time of garbage in the furnace affects the amount of garbage processed

Therefore, it is difficult to meet the various indicators of waste

incineration treatment at the same time by adjusting the movement frequency of grate pieces to incinerate waste with large fluctuations in composition, calorific value, and moisture content.

[0004]

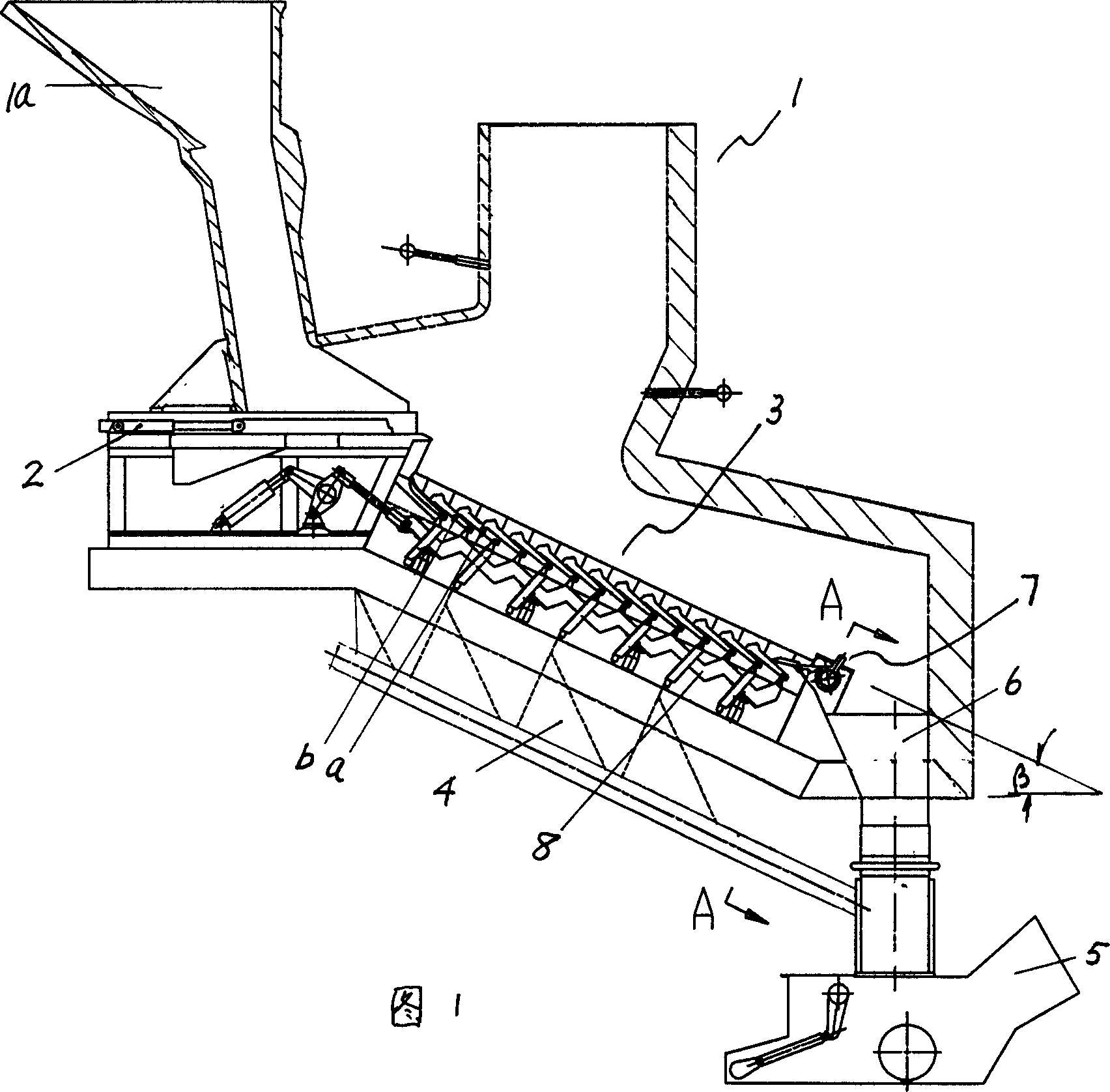

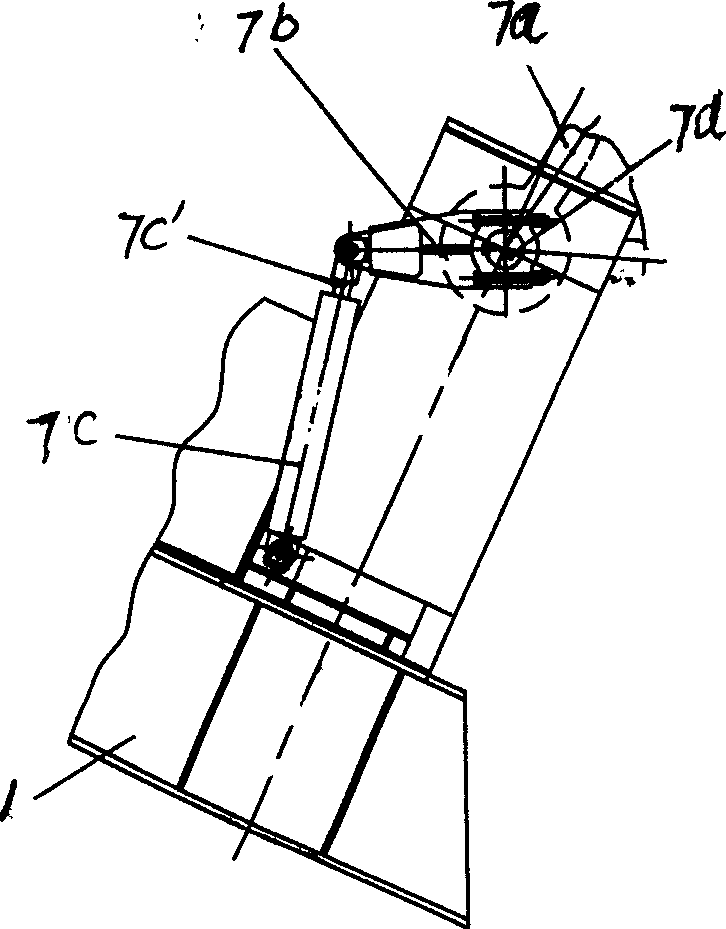

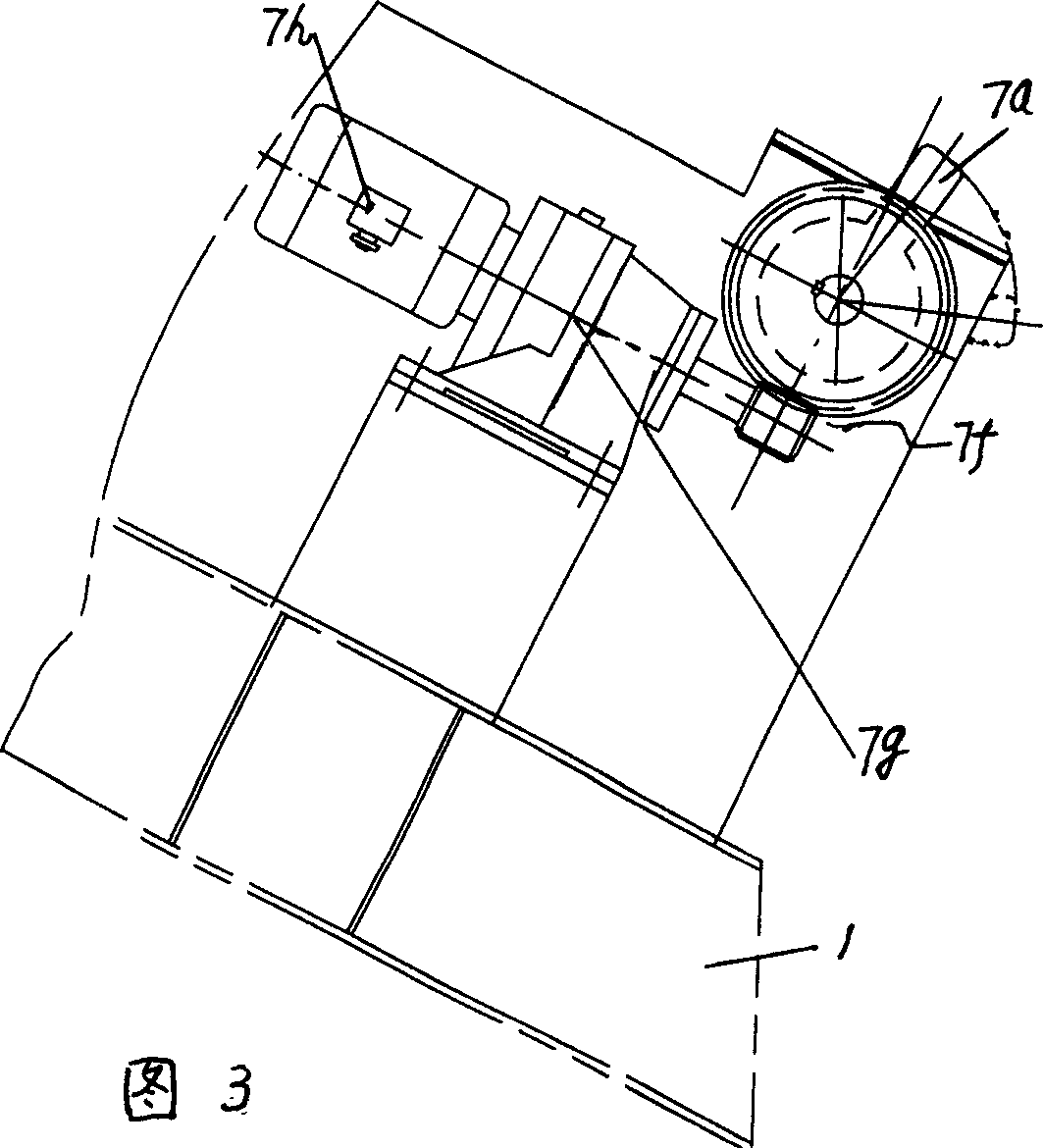

Chinese patent ZL03126962.1 provides "Multi-drive reverse-push grate method and equipment for incinerating garbage", which divides the inclined reciprocating reverse-push grate set in the grate type garbage incinerator into 1 or 2

drying areas , 1 or 2 combustion areas and 1 or 2 embers; the active grates in each area are independently driven by the oil cylinders in each area; The grate action in the

drying section, burning section and

burnout section of waste incineration can be inconsistent, and the speed of the grate action in the

burnout section can be adjusted independently; but it still has the following problems: its multi-stage drive reverse In fact, the push grate can only adjust the material layer by adjusting the action frequency of the reverse push grate at the end stage, and because of the limitation of the grate arrangement angle, the garbage will be affected by gravity after being piled to a certain extent Therefore, it is difficult for this structure to actively control the thickness of the garbage material layer, so it cannot guarantee that the incinerator can always run at a stable load; in addition, its structure is more complicated and the

investment cost of equipment is relatively high.

[0005] To sum up, when using domestic waste incinerators, when the fluctuations of various indicators such as waste composition, calorific value, and moisture content are relatively large, the effect of waste incineration and the rate of

thermal ignition reduction cannot be guaranteed at the same time, and the same kind of furnace type cannot be used for

waste disposal in different areas

Login to View More

Login to View More  Login to View More

Login to View More