Continuous type transmission sludge burning caking furnace

A sludge incineration and agglomeration technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of restricting flue gas recycling, energy waste, flue gas temperature instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

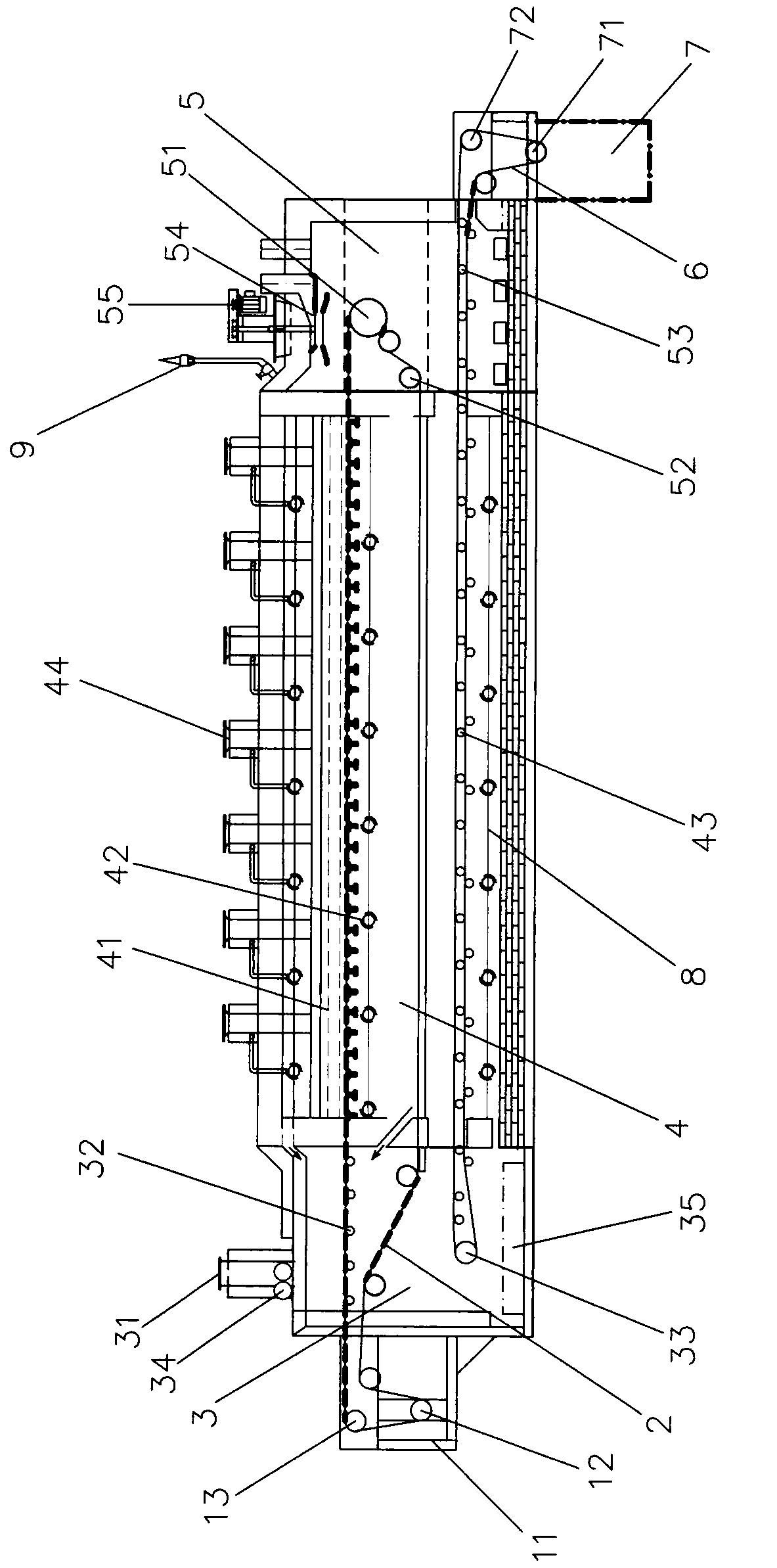

[0024] Such as figure 1 As shown, a continuous conveying sludge incineration agglomeration furnace includes a feeding device, a conveying mesh belt 2, a furnace body system, a side discharge transfer mesh belt 6 and a natural extension trench 7 of the mesh belt;

[0025] The feeding device includes a support 11, a feeder 12 and a feeding guide roller 13; the furnace body system includes a preheating chamber 3, a heating chamber 4 and a water vapor chamber 5; the top of the preheating chamber 3 is provided with a discharge Port 31 and hot and cold air exchange fan 34, the upper part is provided with a preheating roller 32, the lower part is provided with a side discharge transfer mesh belt drive roller 33, and the bottom is provided with a discharge trough 35; the heating chamber 4 is divided into upper and lower layers , the upper layer is provided with a heat-resistant steel muffle tank 41 and a burner 42, the lower layer is provided with a heat-resistant idler roller 43, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com