Incineration method for domestic, medical and building solid waste

A technology for construction solid waste and solid waste, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of reducing drying effect, reducing high-temperature flue gas, reducing high-temperature flue gas in garbage drying box, etc., to achieve drying effect Good, avoid toxic gas, improve the effect of drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0029] A method for incinerating domestic, medical and construction solid waste, characterized in that it comprises the following steps:

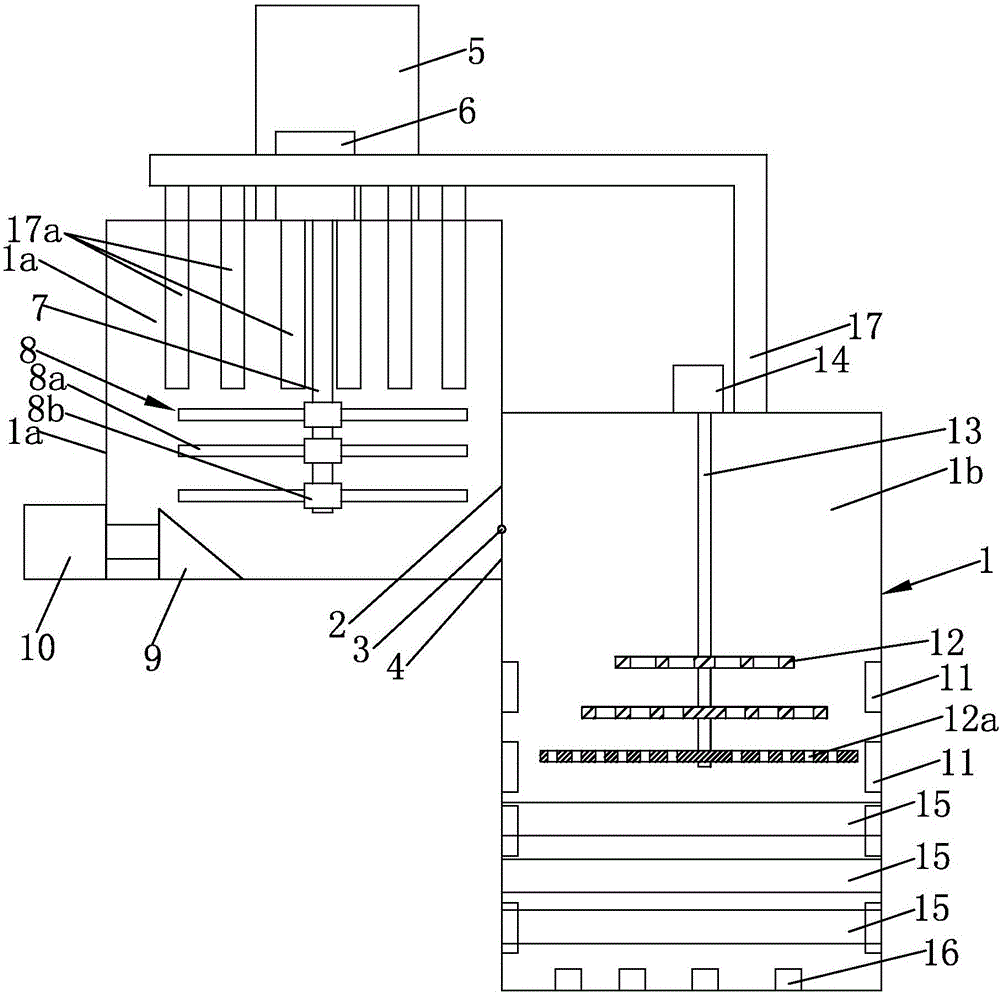

[0030] Step a: Design an incinerator such as figure 1 Shown, a kind of life, medical treatment, the incineration method of building solid waste mainly are made of furnace body 1, fixed flue gas baffle 2, movable flue gas baffle 3, pin 4, garbage inlet pipe 5 and motor 6 etc. Wherein, the inner wall of the furnace body 1 is covered with insulating material, and the inner cavity of the furnace body is composed of an upper chamber 1a and a lower chamber 1b, wherein the upper chamber 1a and the lower chamber 1b are both revolving structures, and the upper chamber The side surface of the lower end portion of 1a directly communicates with the side surface of the upper end portion of the lower chamber 1b. A fixed smoke baffle 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com