High concentration organic waste liquid burning process and device

An organic waste liquid and incineration device technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of unreasonable structure, complex process, low use efficiency, etc., so as to reduce the generation of pollutants and avoid secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

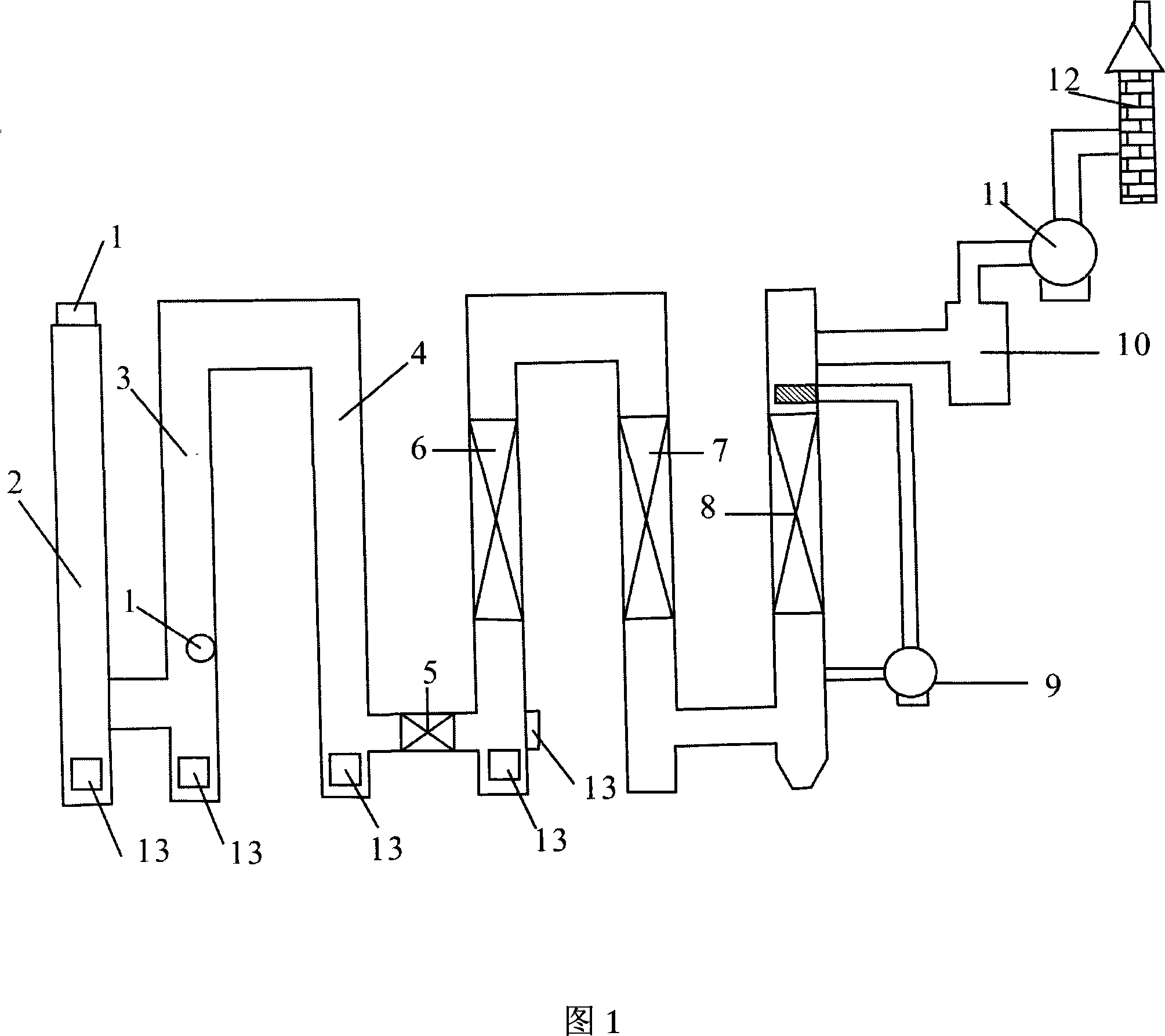

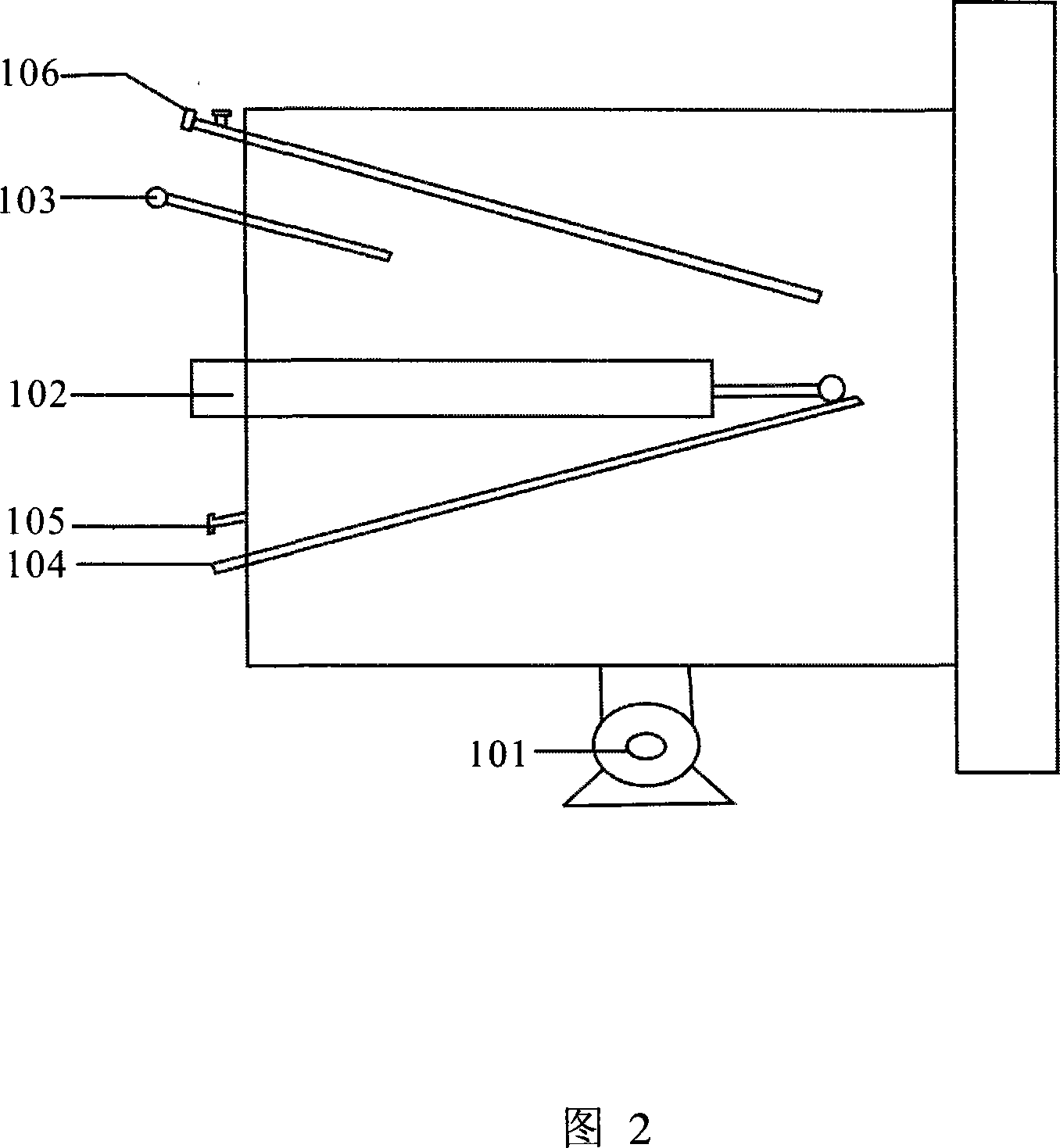

[0021] As shown in Figure 1 and Figure 2, the high-concentration organic waste liquid incineration device is provided with double incinerators, that is, an incinerator 2 and an incinerator 3, and a burner 1 is provided at the top of the incinerator 2 and the middle and lower end of the incinerator 3 , wherein the incinerator 2 and the incinerator 3 are connected through pipelines at the lower part; a settling chamber 4 is also provided, and the top of it is connected with the top of the incinerator 3, and the bottom end of the settling chamber 4 is connected with the waste heat recovery section, and the waste heat recovery The other end of the section is connected to the washing tower 8, and the top of the washing tower 8 is connected to the separation tank 10, the induced draft fan 11 and the chimney 12 in sequence, wherein the burner 1 includes a blower 101, a combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com