Drying and incineration system, and drying and incineration method for sludge

A sludge drying and sludge technology, applied in the field of treatment and sludge drying, can solve the problems of excessive exhaust gas, high energy consumption, and high potential safety hazards, and achieve the effects of fast drying rate, reduced demand and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

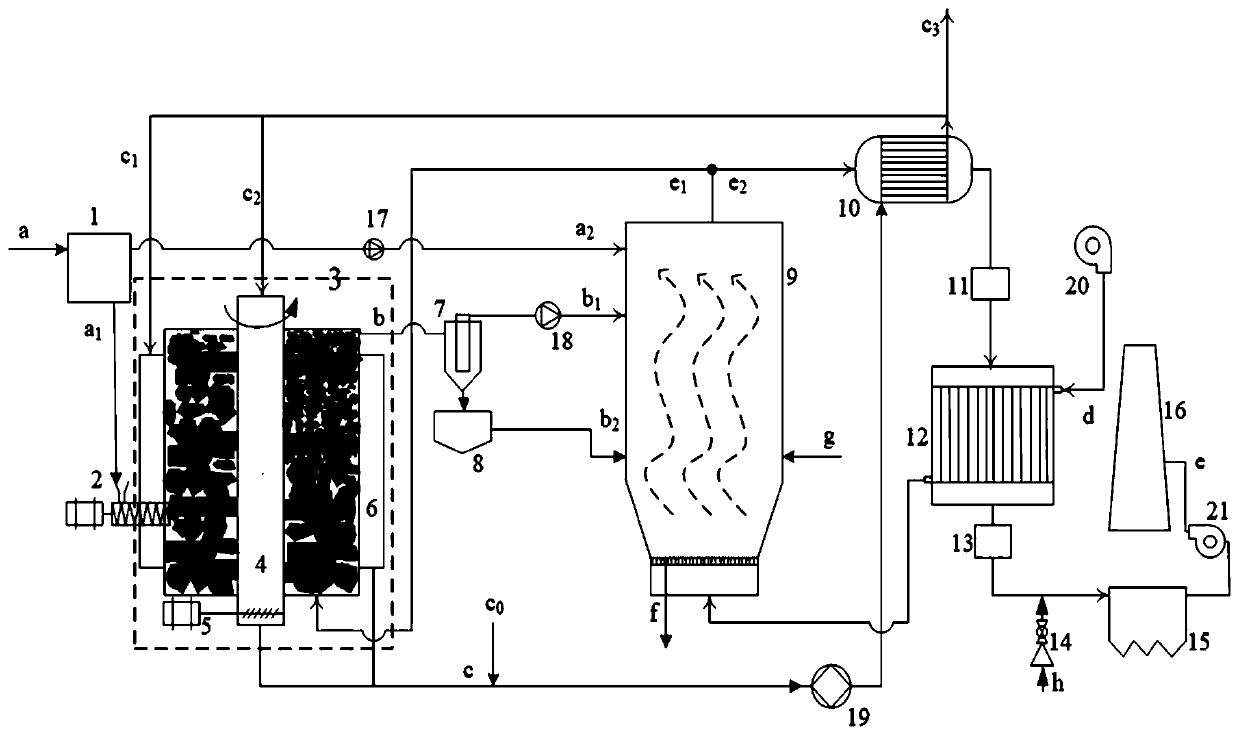

Method used

Image

Examples

Embodiment

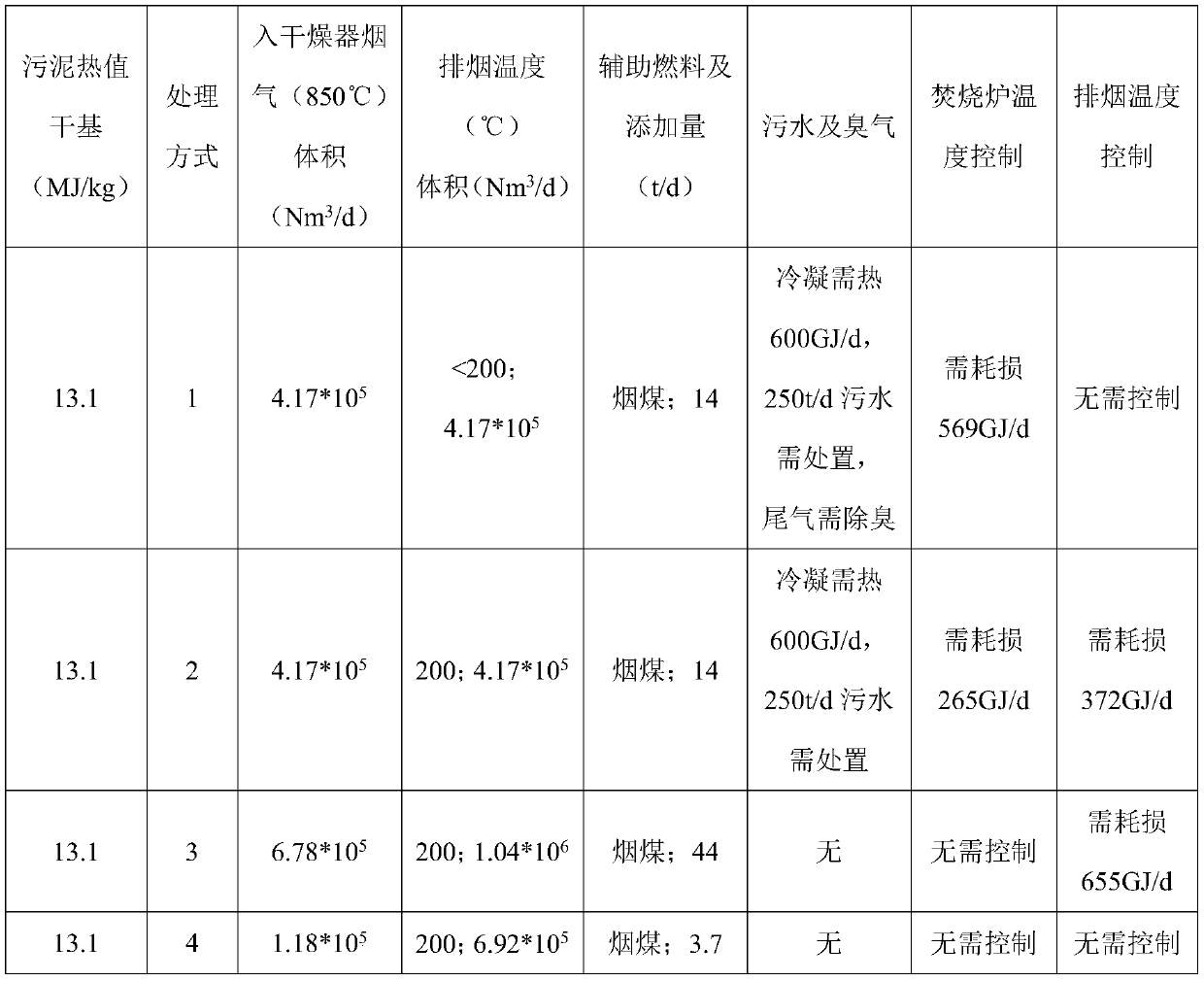

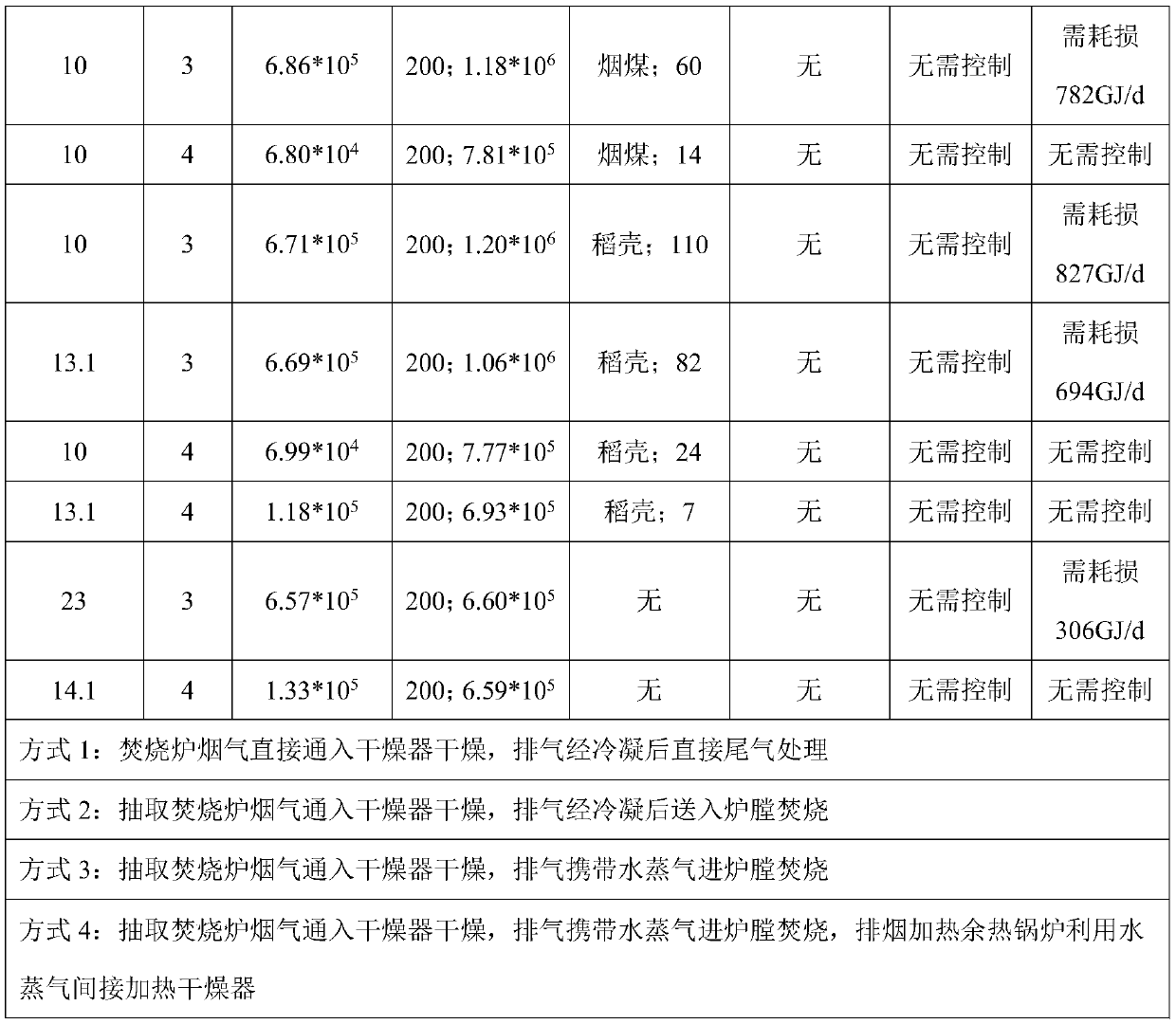

[0048] Taking the sludge from a certain sewage plant around Jiangsu Province (13.1MJ / kg on a dry basis) as an example, 350t / d of wet sludge with a water content of 80% is treated, and the sludge drying and incineration system of the present invention is used for processing (mode 3, 4), and compared with the traditional sludge drying and incineration treatment method (mode 1, 2), and then compared the use of different calorific value sludge and the addition of different auxiliary fuels, the results are shown in Table 1 below; in Table 1, The auxiliary fuel is bituminous coal or rice husk, among which, the calorific value of bituminous coal is 24MJ / kg, and the calorific value of rice husk is 13.5MJ / kg.

[0049] Table 1 Treatment effect of sludge drying and incineration system in different ways

[0050]

[0051]

[0052]It can be seen that the sludge drying and incineration system of the present invention does not require sewage treatment and tail gas deodorization, saving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com