Squeezing type dehydration system adapted for waste paper residue with high water content

A waste paper slag, high moisture technology, applied in the combustion method, combustion type, incinerator and other directions, can solve the problems of cumbersome operation, increased difficulty of waste paper slag, large investment, etc. The effect of incineration performance and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

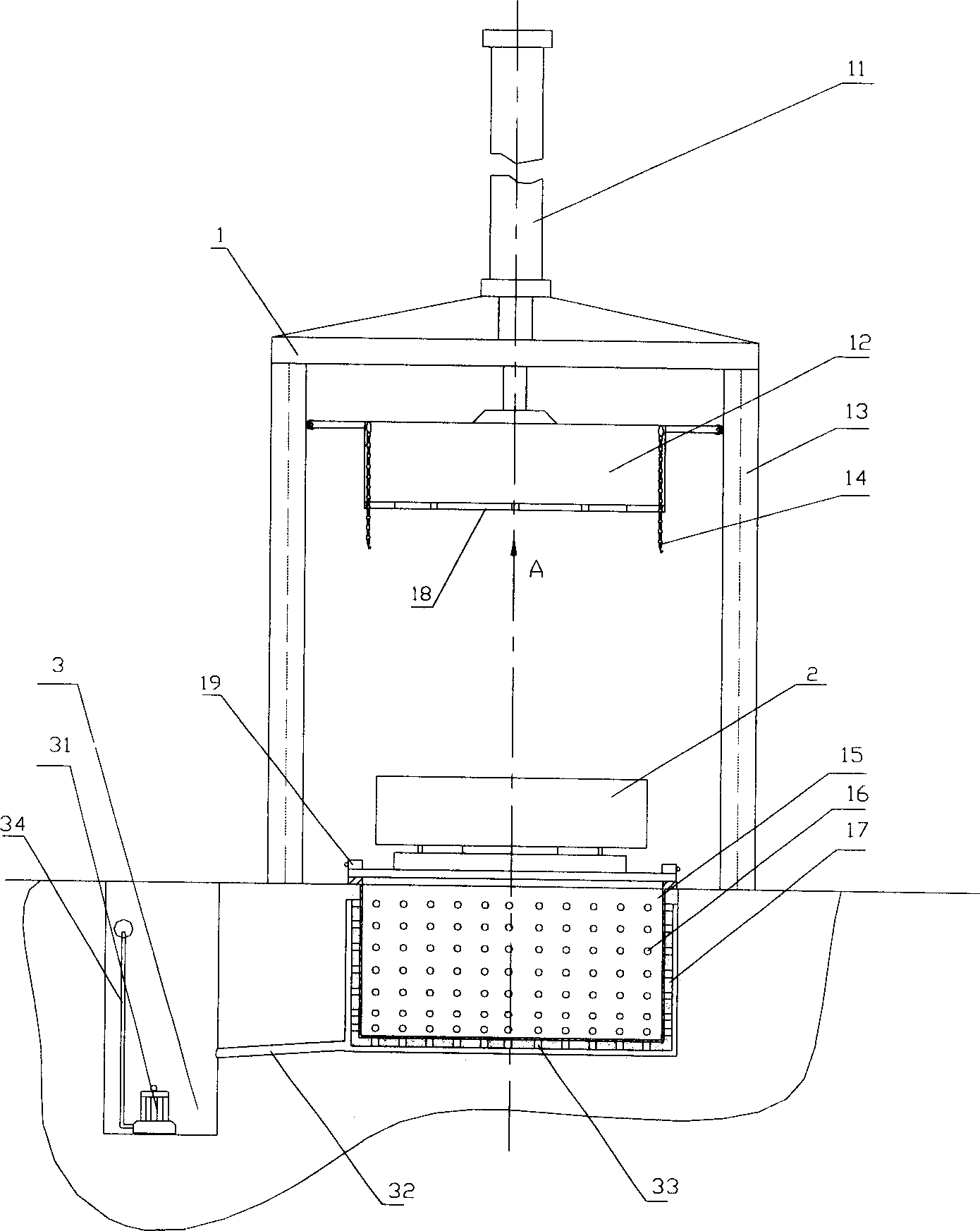

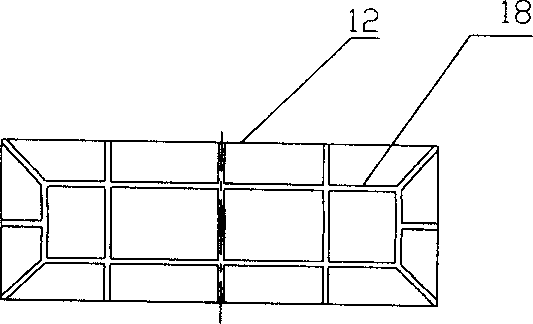

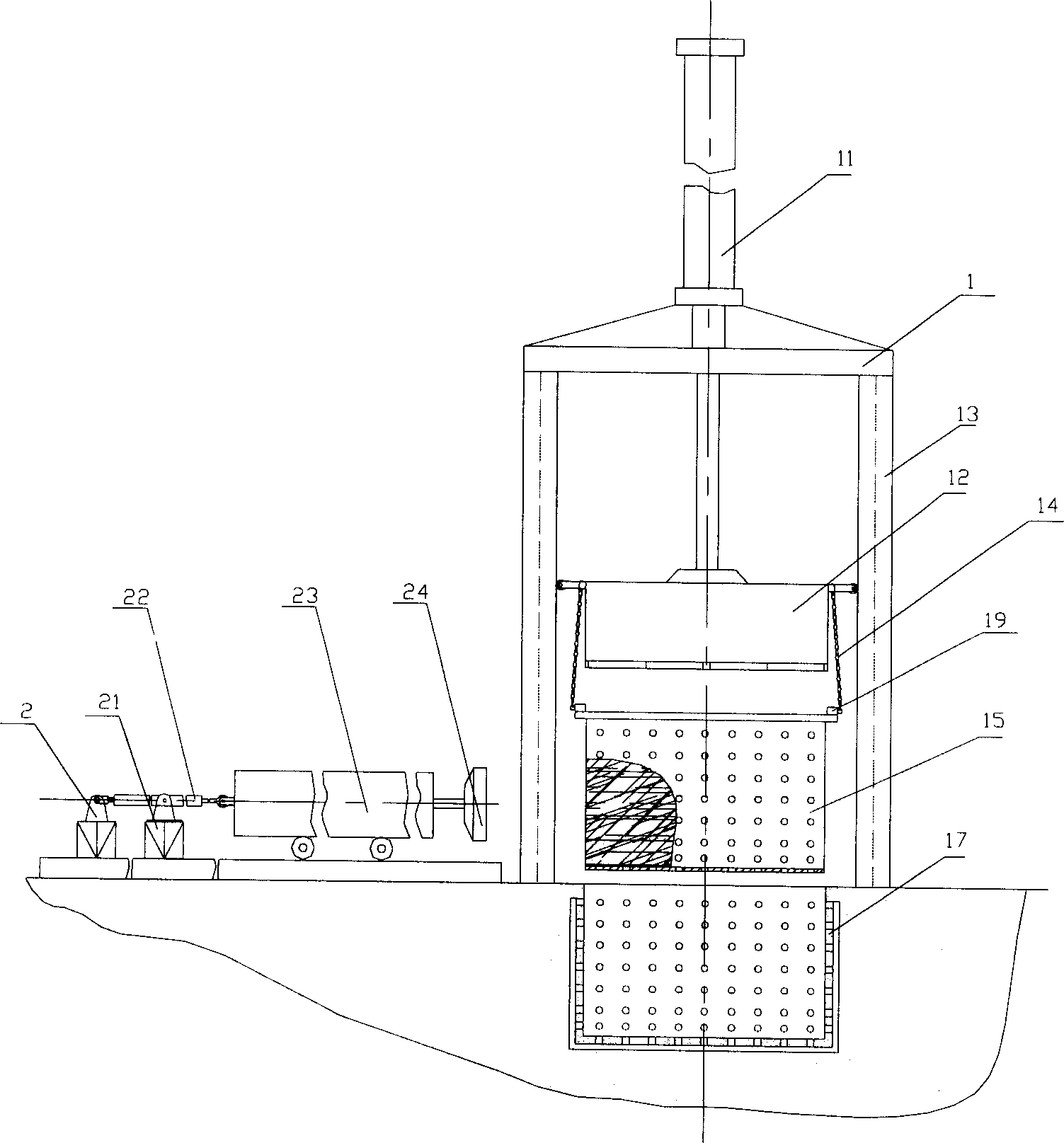

[0013] See Figure 1 to Figure 3 , The present invention includes a press 1, a pusher 2 and a sewage collection well 3. The press 1 consists of a frame 13, a hydraulic cylinder 11 vertically installed above the frame 13, an extrusion plate 12 connected to the bottom end of the hydraulic cylinder 11, and a groove that corresponds to the upper and lower positions of the extrusion plate 12 and is built below the ground. Pit 17 is composed. The pit 17 is equipped with a 凵-shaped steel mold 15 whose top end matches the size of the extrusion plate 12, which can accommodate waste. The wall surface is evenly distributed with drainage holes 16, and the upper end of the 凵-shaped steel mold 15 is provided with a steel chain 14 Ear hook 19. The two sides of the extruded plate 12 are hinged with steel chains 14 which can be flexibly connected with the steel mold 15. The pusher 2 is composed of a hydraulic cylinder 22 that is horizontally hinged and fixed with the ground support 2, a roller 23 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com