Energy-saving incinerator special for chemical industry

An incinerator, chemical technology, applied in the field of energy-saving chemical special incinerators, can solve the problems of energy loss, wasted time, etc., to achieve the effect of improving pulverization and accelerating incineration, accelerating pulverizing and incinerating, and accelerating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

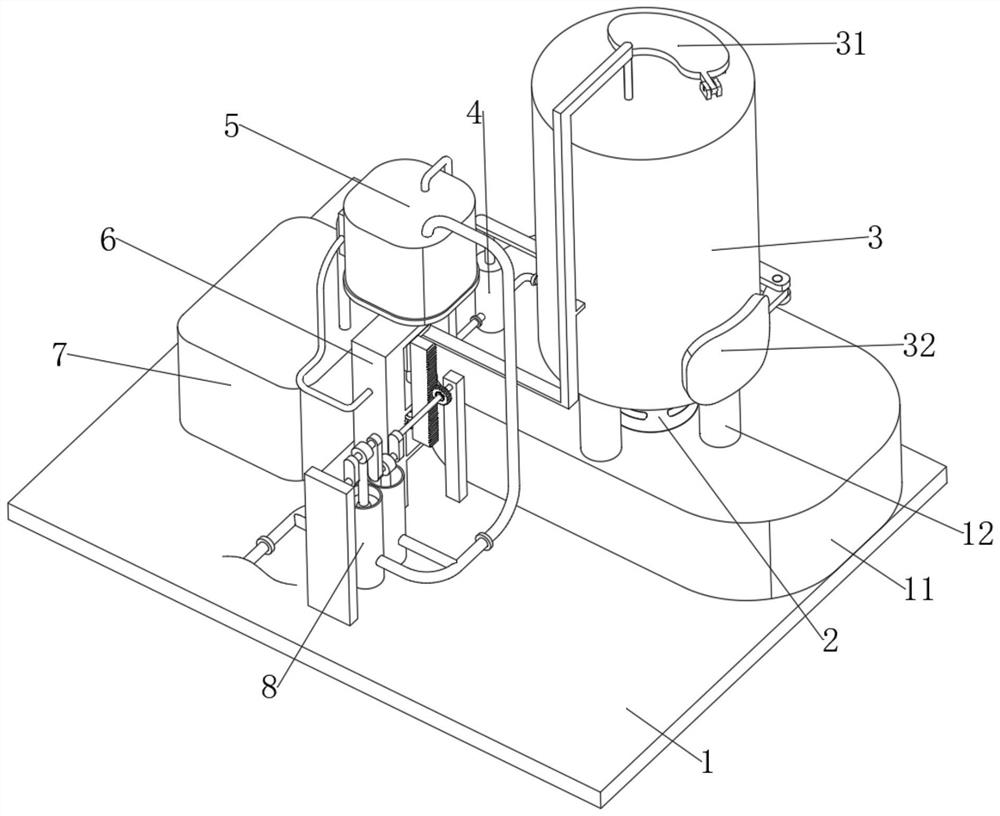

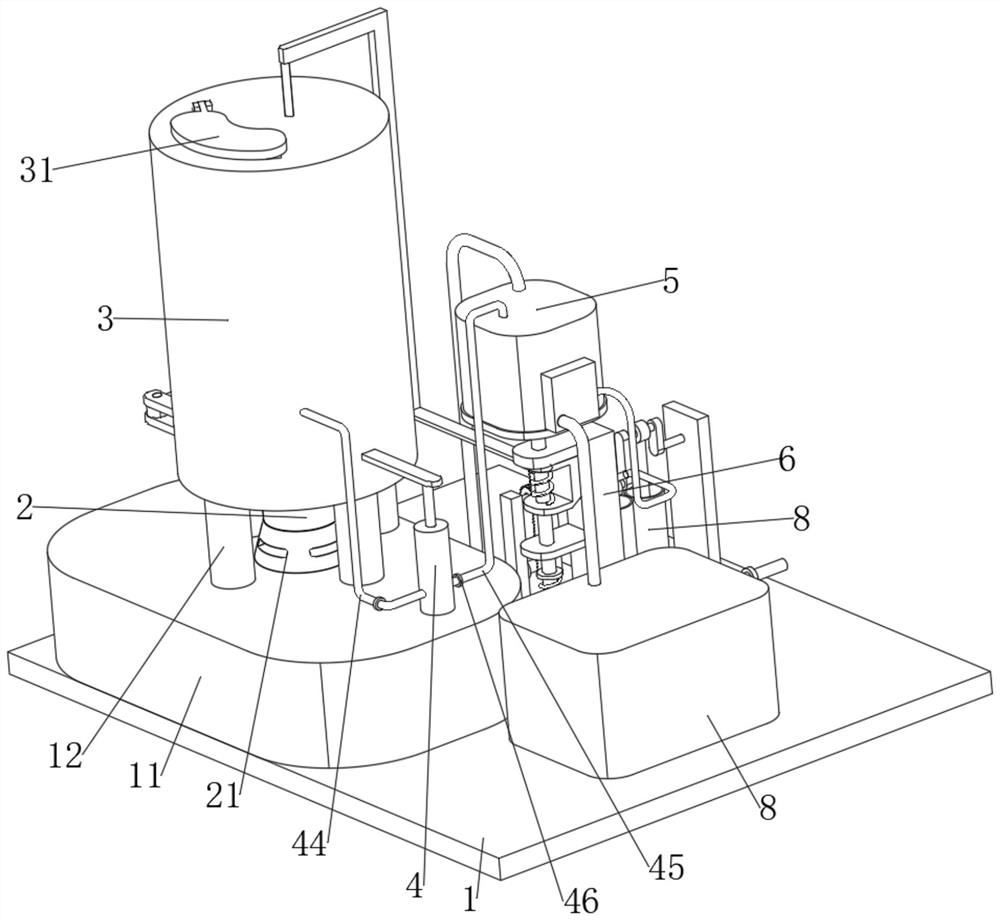

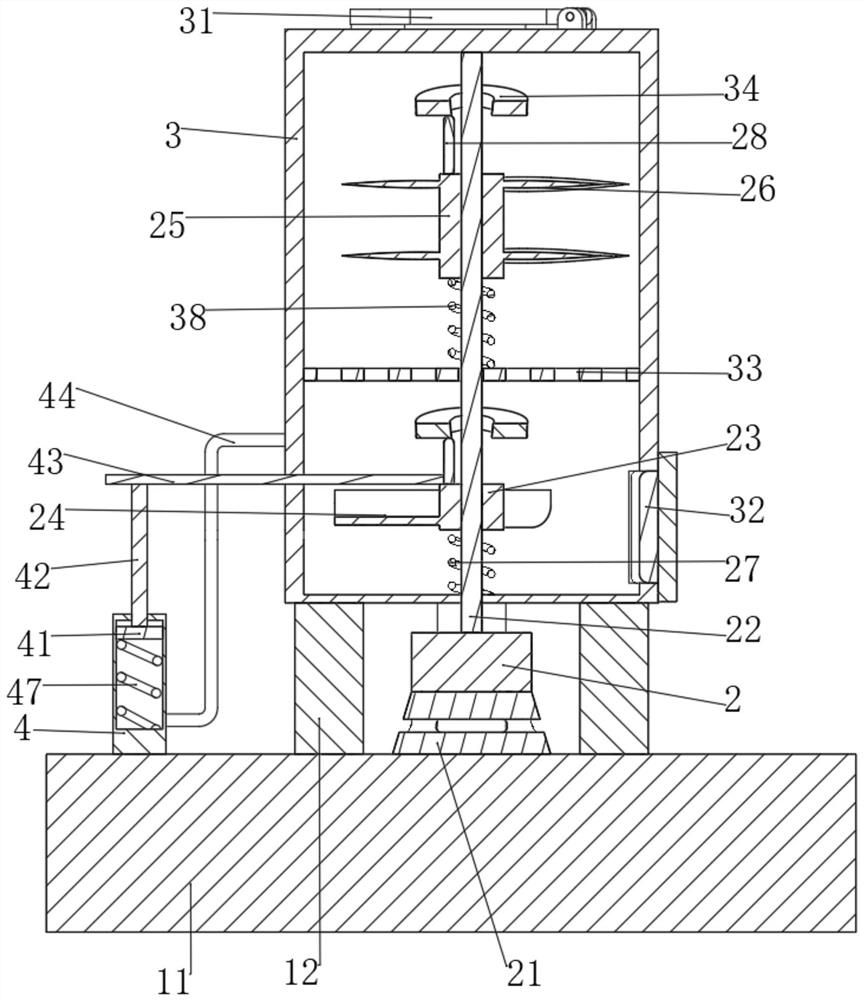

[0032] The present invention provides a technical solution: an energy-saving special incinerator for chemical industry, including a load-bearing plate 1 and a support plate 11, the support plate 11 is fixedly connected to the load-bearing plate 1, and four support columns are fixedly connected to the upper surface of the support plate 11 12. The four supporting columns 12 are fixedly connected with a housing 3, and the housing 3 is provided with a crushing and combustion-supporting mechanism for crushing chemical waste and accelerating the incineration of chemical waste. The upper surface of the housing 3 is provided with a feed port, and the housing 3 The upper surface of the housing 3 is hinged with a feed cover 31 that matches the feed inlet through a pin shaft, and the side of the housing 3 near the support column 12 is provided with a discharge port, and the side of the housing 3 near the support column 12 is hinged with a The discharge cover 32 matched with the discharge ...

Embodiment 2

[0046] It is basically the same as the first embodiment, furthermore, the sliding rod 52 is provided with a replenishing mechanism for replenishing the neutralization tank 5 with alkaline liquid medicine, and the replenishing mechanism includes a The second baffle 64 of the second baffle 64, the end of the sliding rod 52 away from the first baffle 62 is sleeved with a sixth spring 65, and the two ends of the sixth spring 65 are fixedly connected with the second baffle 64 and the support frame 6 respectively, and the sliding frame 61 A rack 9 is fixedly connected to the top, and two support blocks 13 are fixedly connected to the load-bearing plate 1. The opposite surfaces of the two support blocks 13 are fixedly connected to a crankshaft 81 for fixed axis rotation, and a ring 92 is fixedly connected to the arc profile of the crankshaft 81. The circular ring 92 is fixedly connected with multiple sets of cards 93, the circular ring 92 is sleeved with a gear 91, the gear 91 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com