Urban garbage disposal method

A municipal waste and ozone treatment technology, applied in recycling technology, construction waste recycling, solid waste removal, etc., can solve the problems of human injury, complex equipment, large amount of fly ash, etc. Amount used, the effect of reducing harmful ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] 1. After the urban waste is sorted by magnetic separation and winnowing using the garbage pre-selector, it is sorted manually as much as possible. The main sorting is to detect fruits and vegetables, glass, scrap metal, and construction waste, and there is no need to sort out plastic products .

[0034] 2. The sorted municipal waste is crushed to less than 10mm by a crusher.

[0035] 3. Pour the crushed municipal waste into the mixer, add coal slime and sludge for mixing and stirring, the weight ratio of coal slime, sludge and municipal waste is 0.5:0.5:1.

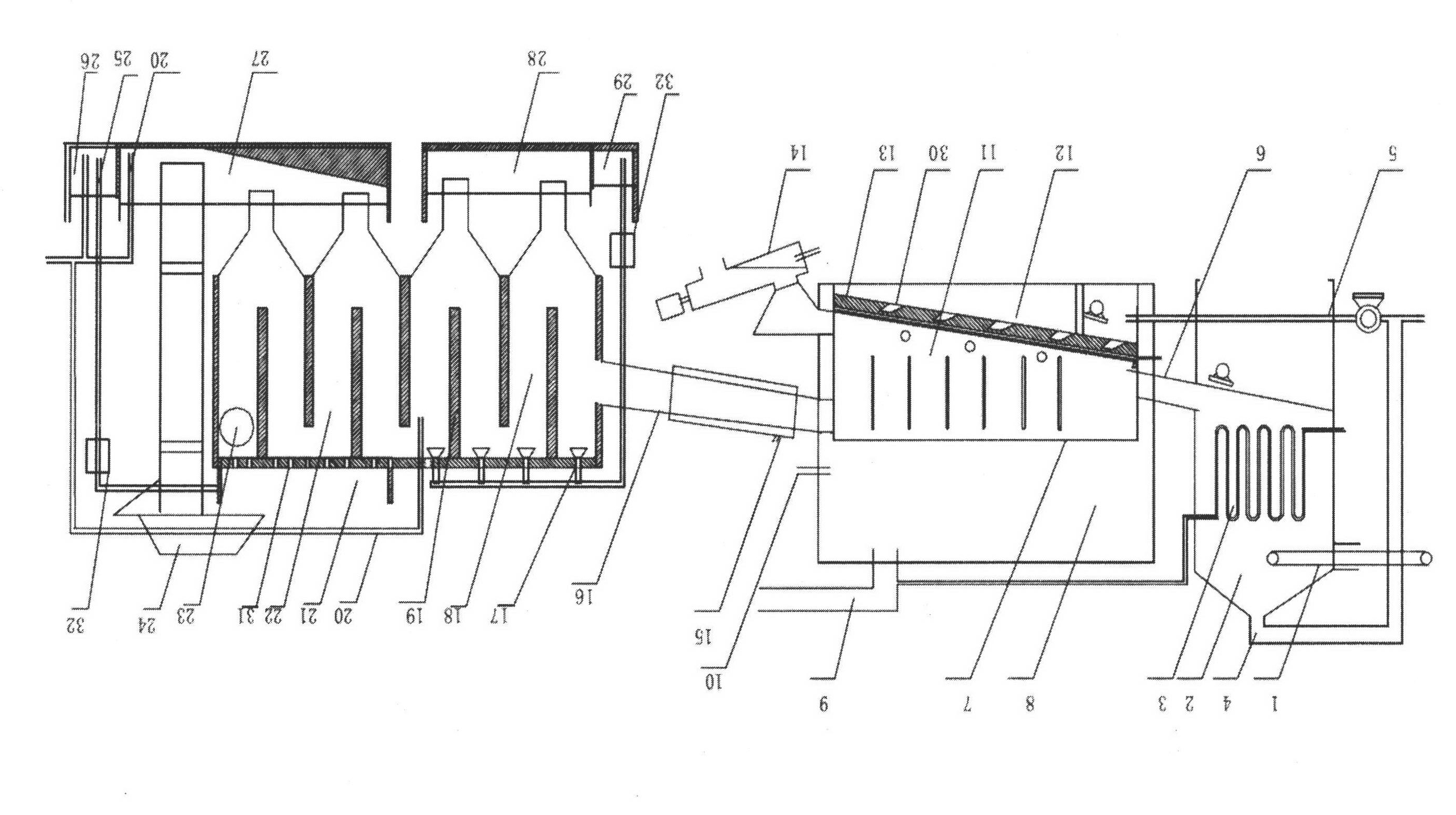

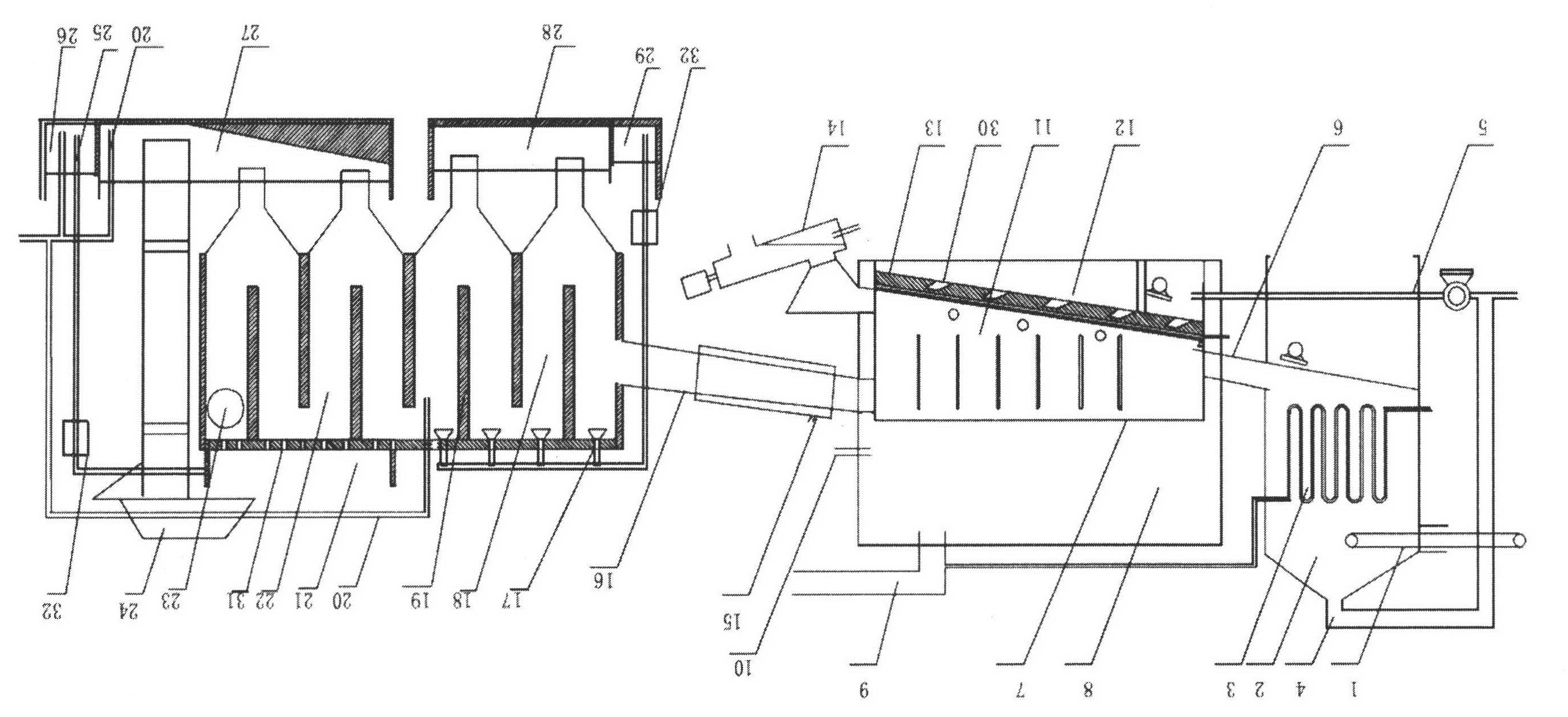

[0036] 4. Put the urban waste mixed with coal slime and sludge into the sealed dry incineration boiler with fly ash treatment through the belt for incineration and fly ash treatment, such as figure 1 As shown, the process is as follows:

[0037] The mixed urban waste is conveyed to the drying equipment 2 through the conveyor belt 1. After being dried in the serpentine dryer 3, the urban waste falls to the slope at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com