Touch panel

A touch panel and substrate technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of increasing the number of parts and manufacturing costs, and prevent the increase in the number of parts and manufacturing costs. The effect of reducing and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

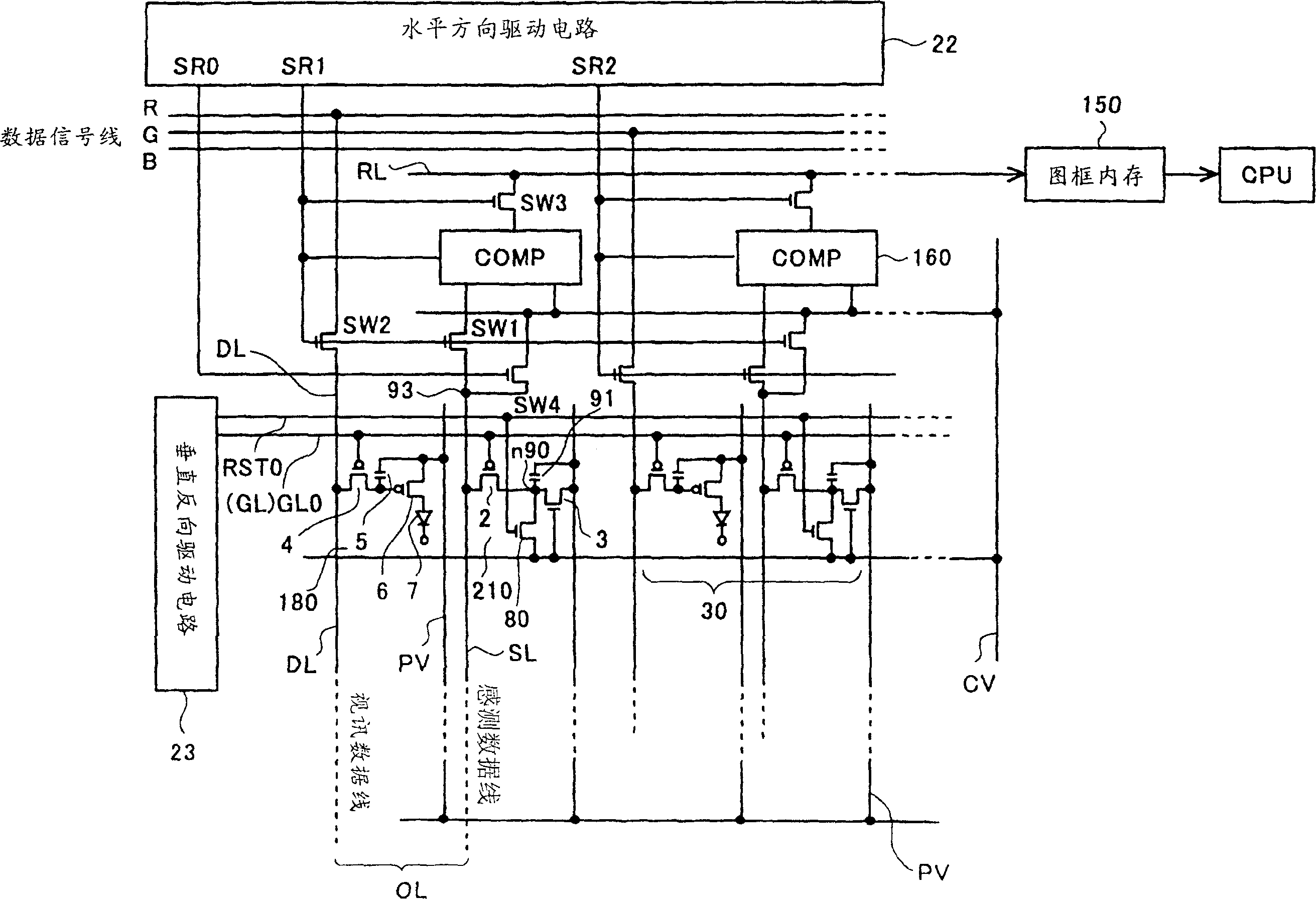

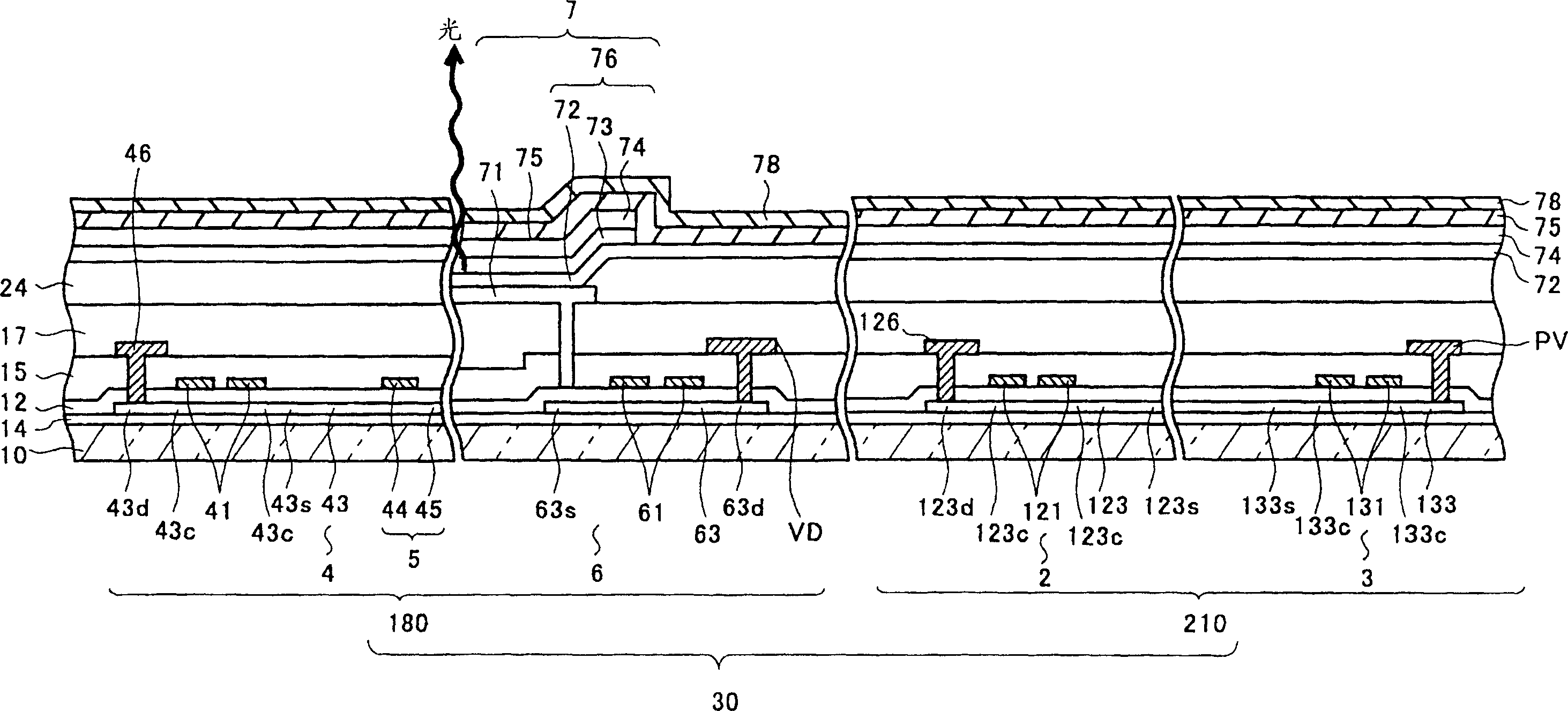

[0043] the following by means of Figure 1 to Figure 19 , to describe the embodiments of the present invention in detail.

[0044] Figure 1 to Figure 5 It is the first example illustrating the present invention.

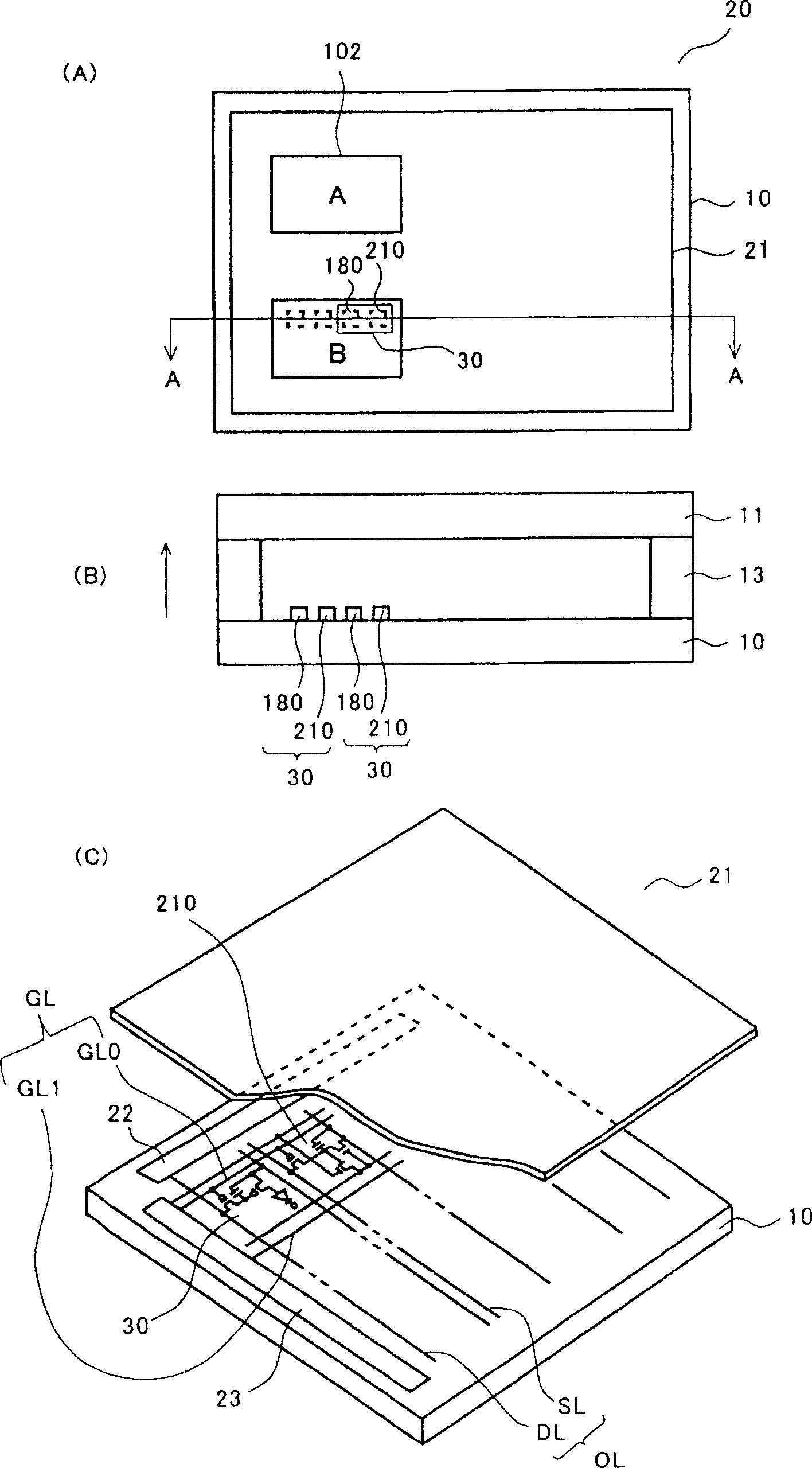

[0045] figure 1 is a schematic diagram illustrating the touch panel of this embodiment, figure 1 (A) is a floor plan, figure 1 (B) for figure 1 A schematic A-A sectional view of (A), figure 1 (C) is an exploded oblique view.

[0046] The touch panel 20 includes a display unit 21 in which display pixels 30 are arranged in a matrix on a substrate 10 .

[0047] like figure 1 As shown in (A), the substrate 10 is an insulating substrate such as glass. On the substrate 10 , for example, display pixels 30 are used to display buttons 102 for a user to perform specific operations. The opposite substrate 11 is a transparent substrate such as glass that allows light from the display pixels 30 to pass through. The opposite substrate 11 and the substrate 10 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com