Lighting device for testing substrate

A technology for lighting devices and substrates, which is applied to measurement devices, instruments, radiation pyrometry, etc., can solve the problems of poor accuracy, long inspection time, and inconvenient inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

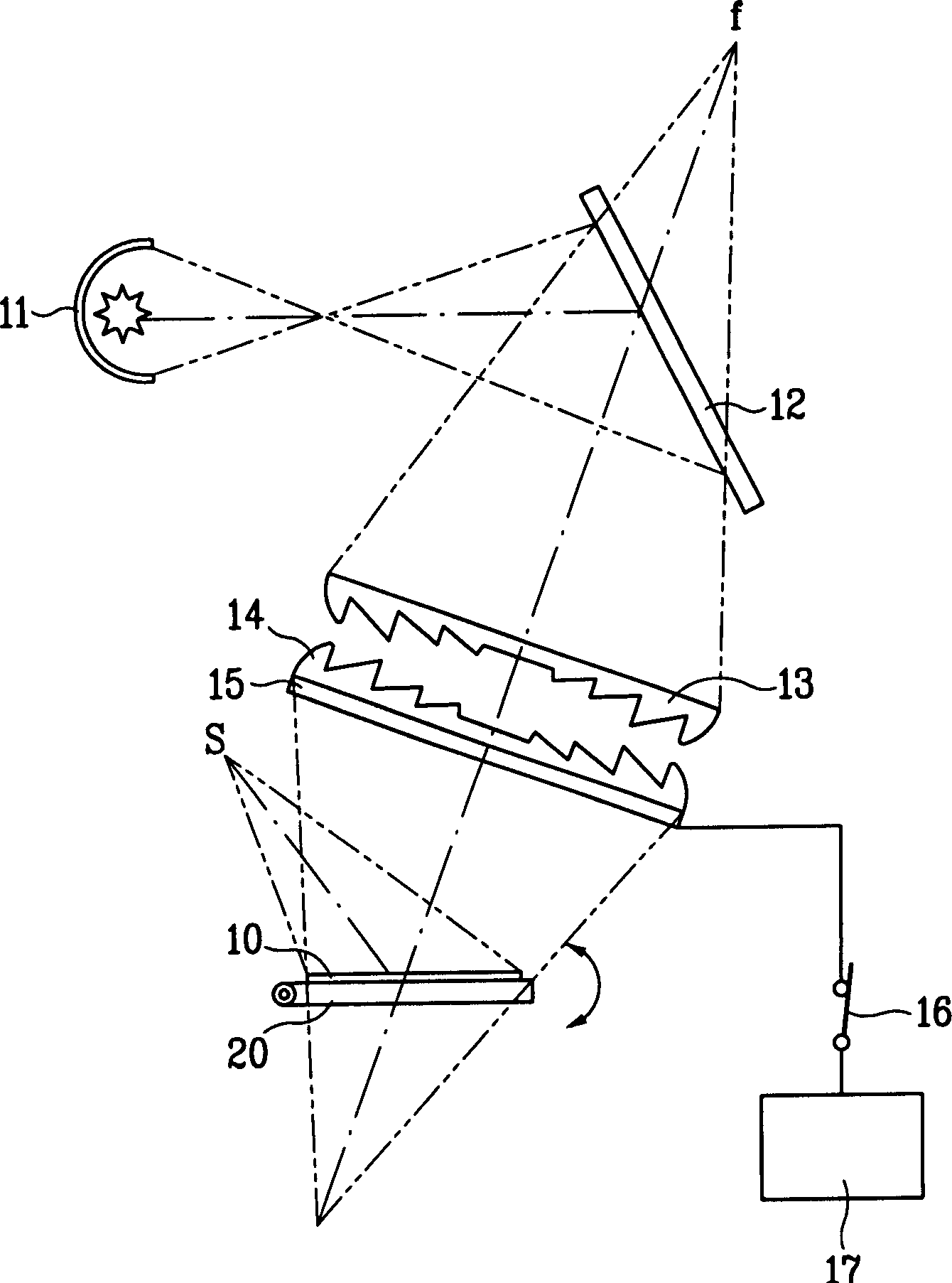

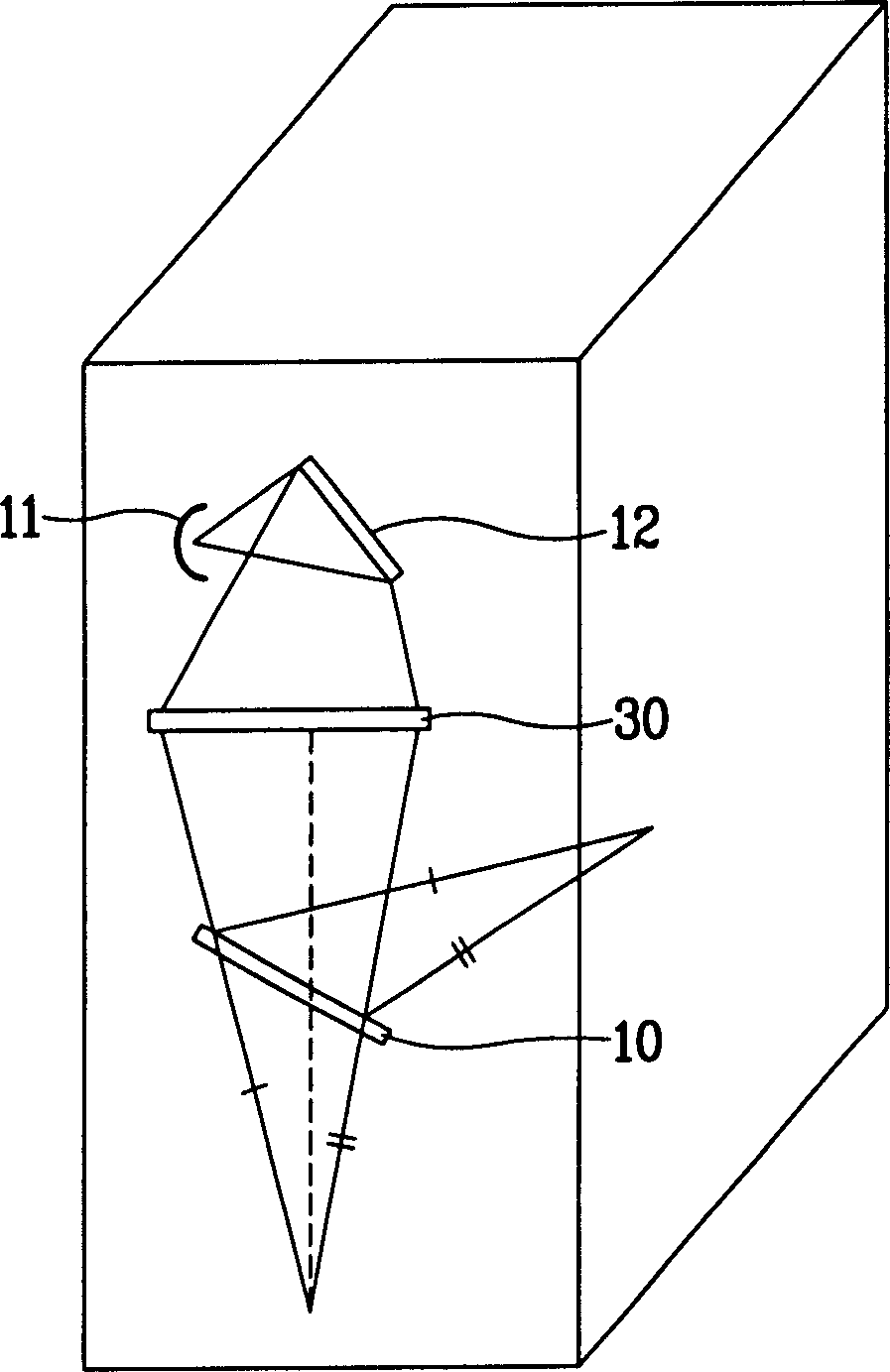

[0042] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will now be described in detail with reference to preferred embodiments of the present invention and with reference to the accompanying drawings. attached Figure 5A and 5B The shown embodiment illustrates an illumination device for inspecting a substrate according to a first embodiment of the present invention when only one illumination device is used.

[0043] see Figure 5A , the illuminating device for inspecting substrates comprises: a mirror 120, which is used to reflect light from a light source 110, which moves in an up / down or left / right direction on a curved surface; and a Fresnel lens 200, the Fresnel lens is used to focus the diverging light from the mirror 120 to a focal point 'P' and illuminate the substrate 300 on the stage.

[0044] In this case, see Figure 5B , the divergent light reflected by the mirror 120 is focused by the Fresnel lens 200 and irradiated to the substrate 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com