Improved magnesium method flue gas desulphurization technique

An improved, flue gas technology used in separation methods, chemical instruments and methods, dispersed particle separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

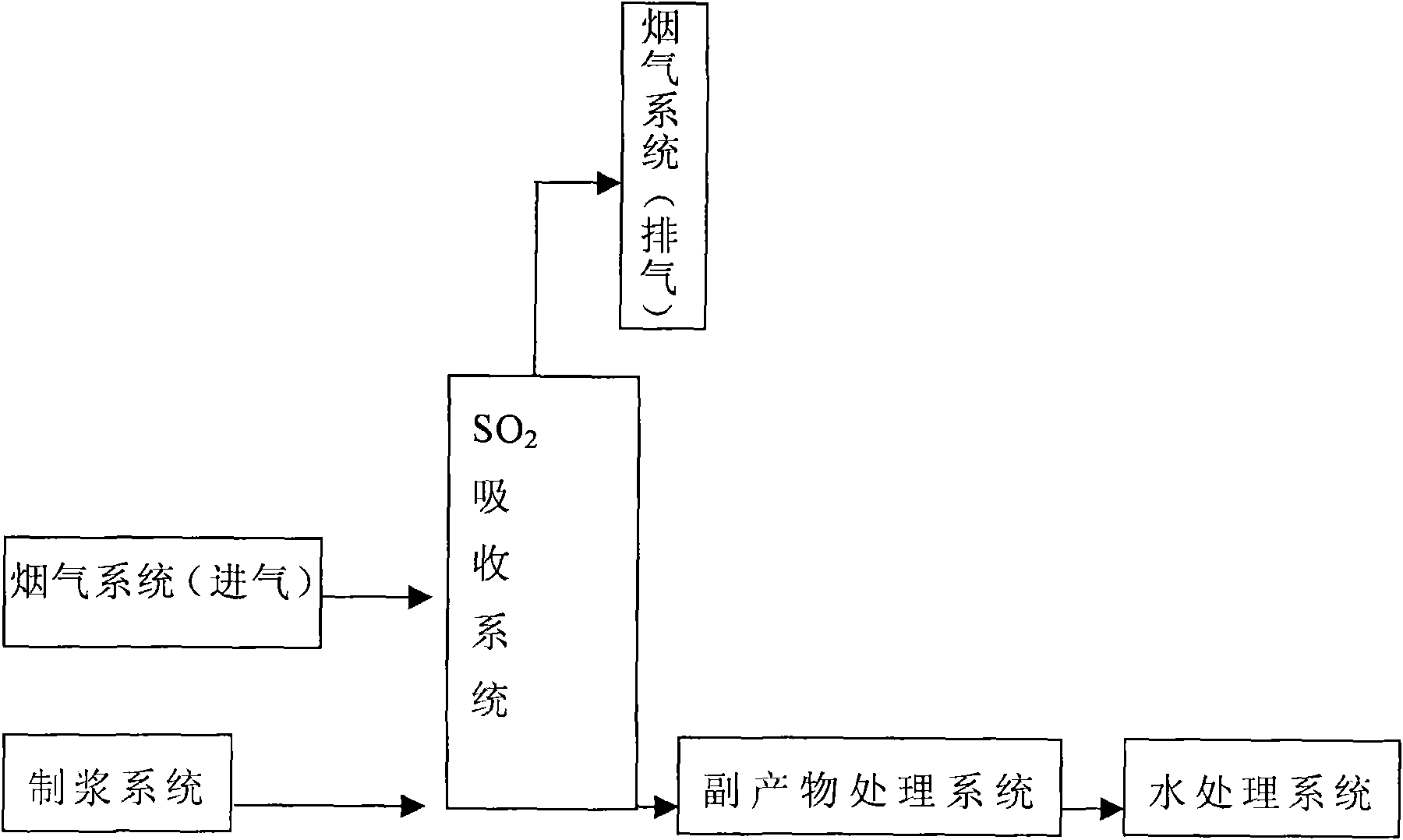

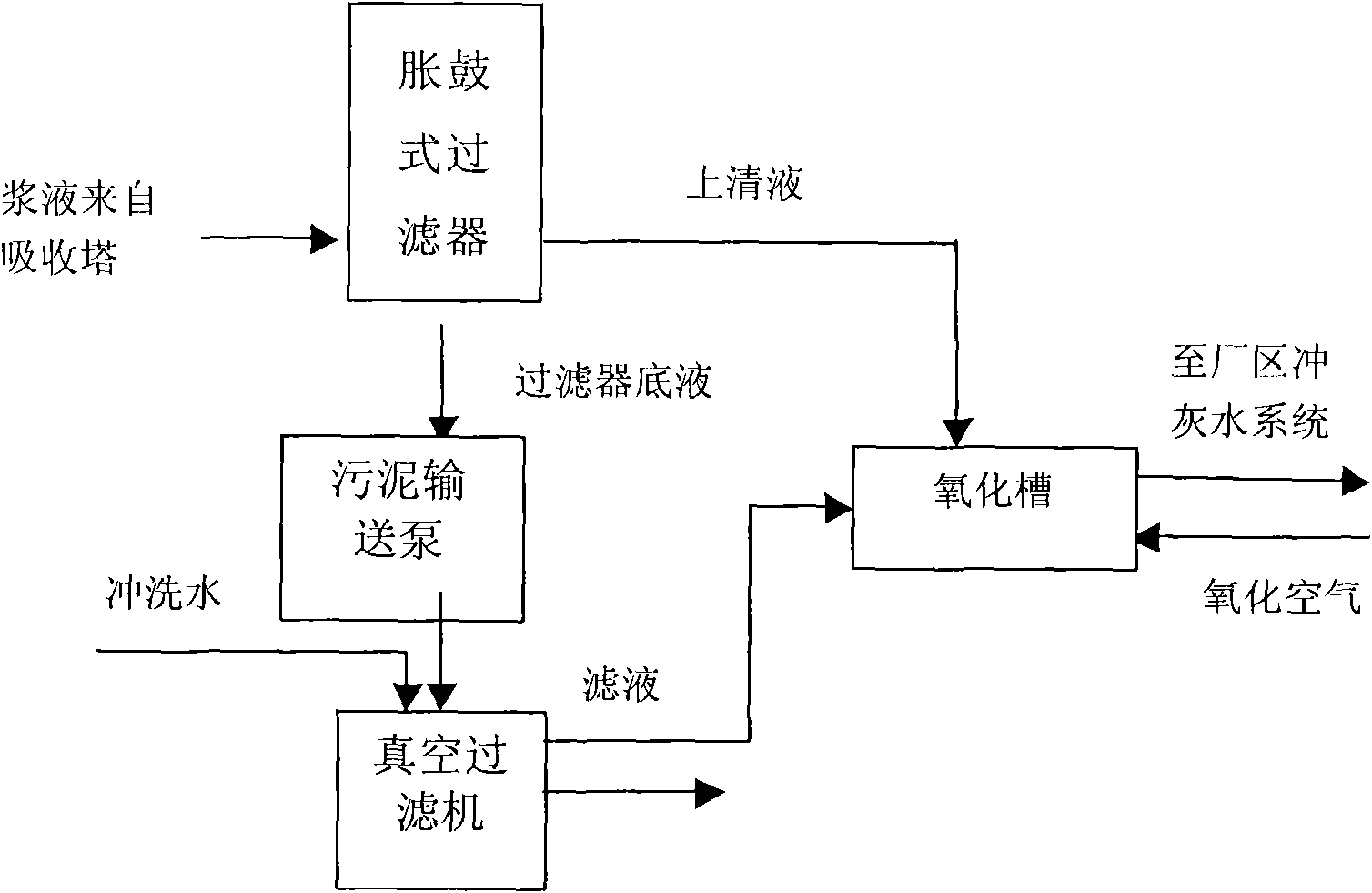

[0183] The method of embodiment 1 is industrial method, comprises following flow process:

[0184] (1) Process 1: pulping system:

[0185] raw material:

[0186] Magnesium oxide powder desulfurizer (particle size between 150 and 250 mesh)

[0187] Water (ratio with the desulfurizer is: 1 part of magnesium oxide desulfurizer and 2.3 parts by weight of water)

[0188] process

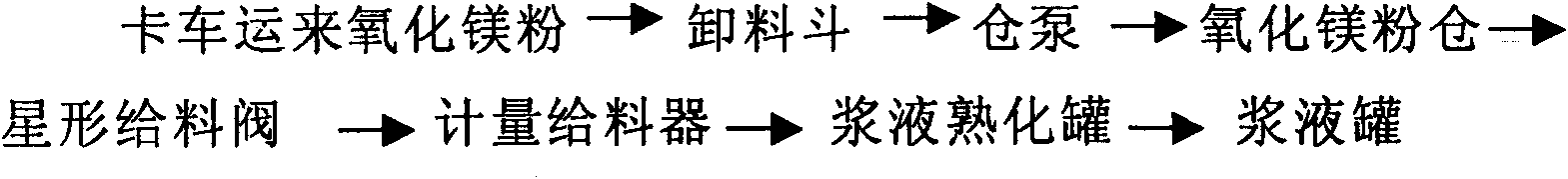

[0189] The system flow is as follows image 3 Shown:

[0190] The magnesia powder in the unloading hopper is pneumatically conveyed to the magnesia powder silo by the warehouse pump, and the magnesia powder is metered and then input into the aging tank, and mixed with the pulping water from the process water system and the steam in the factory area according to a certain ratio for aging ( Mix 1 part of magnesium oxide desulfurizer with 2.3 parts by weight of water and 0.1 part of water vapor at 20°C, and ripen at 50-60°C for 3 hours), the matured slurry is transported to the slurry tank through the s...

Embodiment 3

[0216] The process of embodiment 3 is similar to embodiment 1, the difference is that,

[0217] In the pulping system, 1 part of magnesium oxide desulfurizer is mixed with 5 parts by weight of water and 0.1 part by weight of steam at °C to generate magnesium hydroxide slurry, which is aged at 80 °C for 2 hours to obtain the slurry of desulfurizer.

[0218] SO 2 In the absorption system, the tower body of the spray absorption tower is a cylindrical body with a constant diameter at the upper and lower parts, and a slurry circulation pump is installed at the lower part of the cylindrical body.

[0219] The obtained technical indicators are as follows:

[0220] Desulfurization efficiency is greater than 95%

[0221] For a 220t / h boiler, the hourly power consumption of this technology is less than 400kW

[0222] The resistance drop of the absorption tower is 600-800Pa.

[0223] Example 3

[0224] The flow process of embodiment 3 is similar to embodiment 1, and difference is, (...

Embodiment 4

[0227] The process of embodiment 4 is similar to that of embodiment 1, the difference is that (1) in the pulping system of process one, a dust removal system is set at the top of the discharge hopper and the powder bin:

[0228] The process of the dust removal system is as follows: Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com