Platy workpiece paint spraying device for machining

A technology for machining plate-shaped workpieces, which is applied in the field of painting devices for plate-shaped workpieces for mechanical processing, can solve the problems of high requirements for operators, poor quality of manual painting, heavy labor intensity and workload, etc., and achieve quality improvement and expansion Painted areas, the effect of reducing work intensity and difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

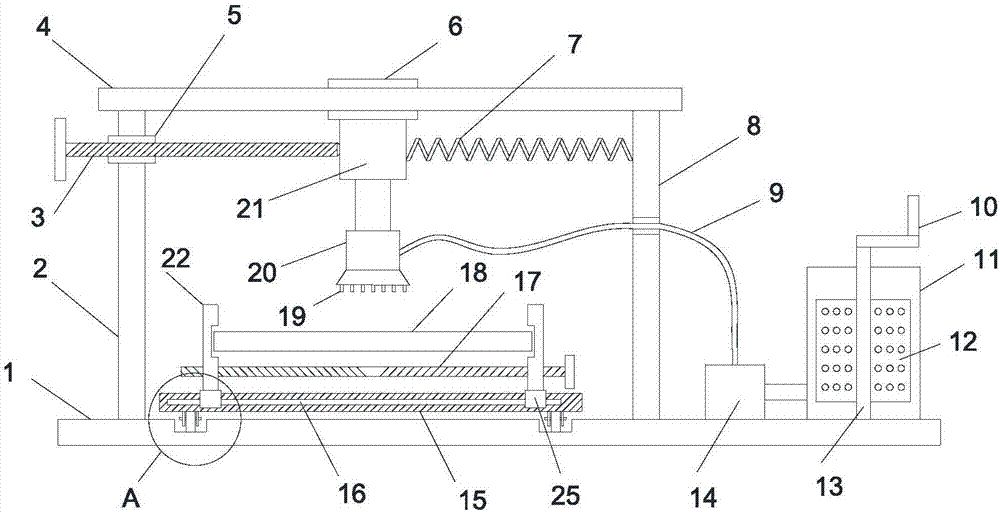

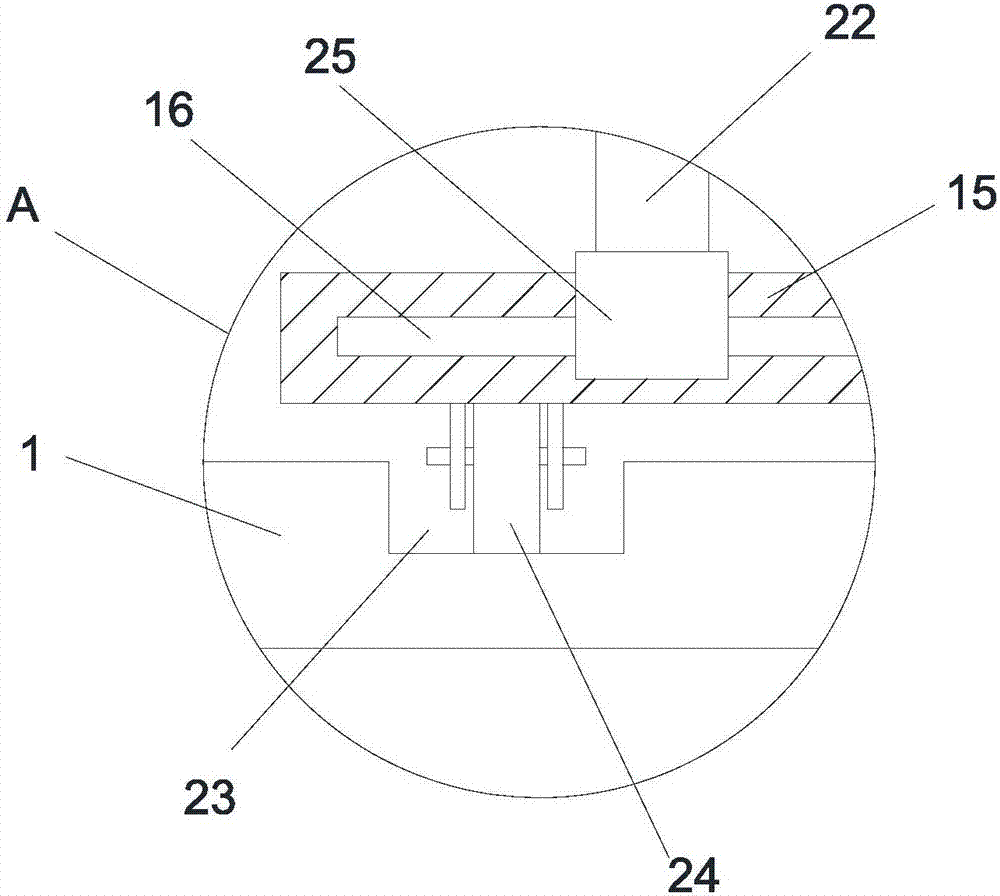

[0016] see Figure 1-2 , a paint spraying device for plate-shaped workpieces for mechanical processing, comprising a base plate 1, a left column 2 and a right column 8 are vertically fixedly installed on the base plate 1, a threaded sleeve 5 is provided on the left column 2, and a threaded sleeve 5 is installed inside the threaded sleeve 5 The first screw rod 3 is arranged horizontally through the thread fit, and the top plate 4 is fixedly installed horizontally on the left column 2 and the right column 8, and the sliding sleeve 6 is set on the top plate 4, and the bottom surface of the sliding sleeve 6 is vertically inverted and equipped with a telescopic Hydraulic cylinder 21, the right end of the first screw mandrel 3 abuts against the left side of the telescopic hydraulic cylinder 21, the lower end of the telescopic hydraulic cylinder 21 is fixedly eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com