Method for improving SO2 concentration in acid making technique with decomposition of calcium sulphate

A calcium sulfate, SO2 technology, applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of reduced calcium sulfate decomposition rate, reduced decomposition rate and desulfurization rate, complicated production control process, etc., to achieve stable production process and increase the concentration of SO2 , The stable effect of sulfuric acid production system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

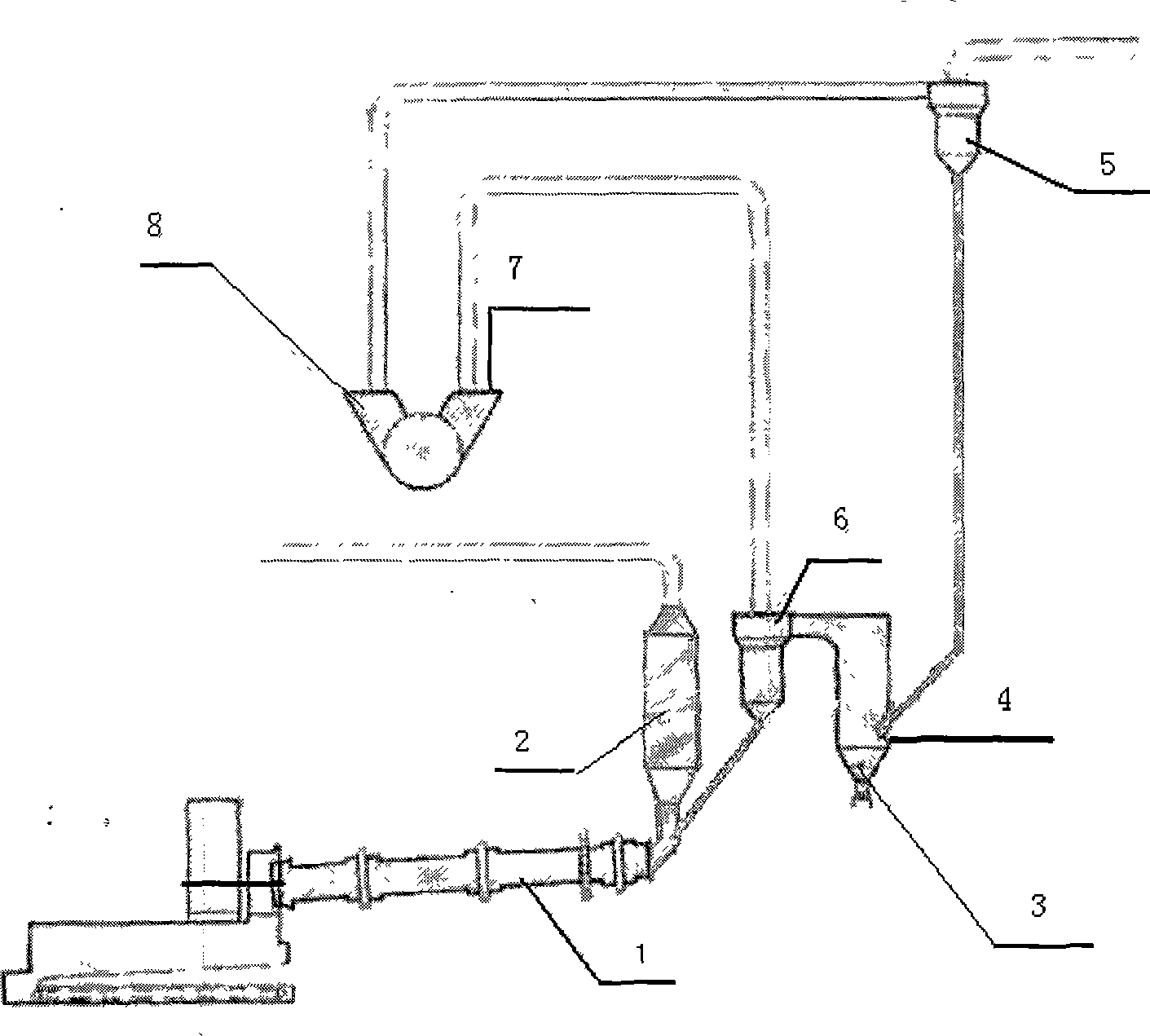

[0026] The phosphogypsum obtained in the production of wet-process phosphoric acid, such as phosphogypsum containing 9-13% of external moisture, is directly added to the rotary hammer drying commonly used in clinker firing in cement plants from the feeding port 7 In the crusher 8, the exhaust gas below 1000°C from the calciner 3 passes through the pipeline and the preheater 6 for heat exchange and then enters the cyclone separator 7, and the separated material enters the calciner 3, and the CO produced by the combustion of pulverized coal Calcium sulfate is reduced and decomposed into calcium sulfide as a reducing agent; the solid materials separated by the cyclone separator 6 all enter the rotary kiln 1, and are mixed with the calcium sulfate distributed from the cyclone separator 5 into the preheater of the kiln series preheater Enter the rotary kiln and react in the kiln to obtain SO 2 Gas, CaO, and solid materials are decomposed by further raising the temperature and react...

Embodiment 2

[0028] In implementing example 1, 3-calcining furnace and 6-cyclone type separator are replaced with rotary kiln, and other is with implementing example 1.

Embodiment 3

[0030] After drying the calcium sulfate to obtain calcium sulfate hemihydrate or calcium sulfate anhydrous, add other raw materials to meet the requirements of the cement clinker formula and mix them evenly, then add them to Example 1 or 2, and add one or more cyclone preheaters 5 is realized by replacing the method of drying crusher 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com