Process for concentrating diluted sulfuric acid and removing impurities

A production method and technology of dilute sulfuric acid, applied in the direction of sulfur trioxide/sulfuric acid, chemical instruments and methods, sulfur compounds, etc., can solve problems such as shortening the process flow, reducing processing operation costs, reducing investment in concentrated dilute sulfuric acid equipment, etc., to achieve simplification process, shorten the production process, and reduce the effect of device investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

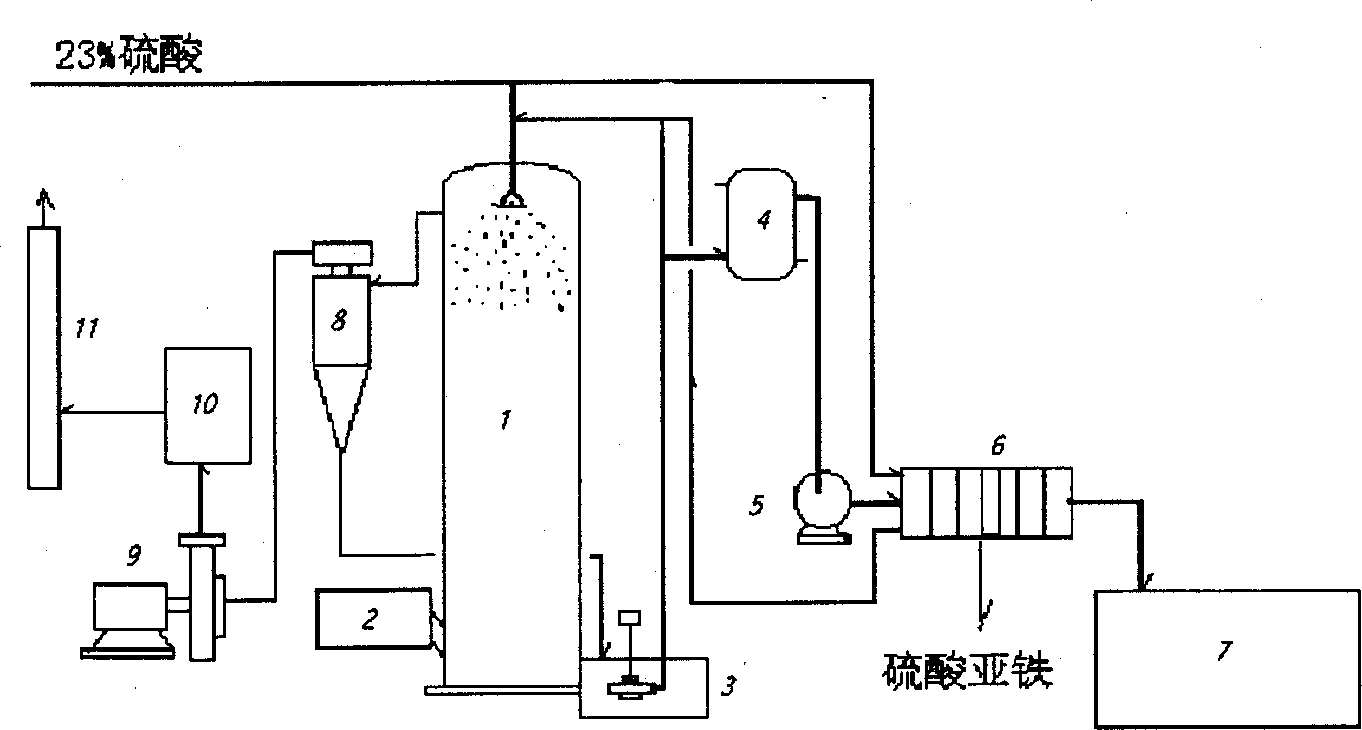

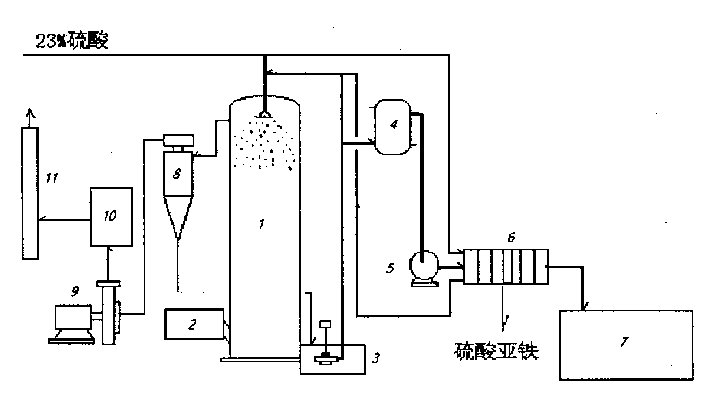

Image

Examples

Embodiment 1

[0033] Using natural gas combustion tail gas as the heat source, 133Kg of dilute sulfuric acid per hour is fed into the simulated spray concentration tower (its main composition is: H 2 SO 4 22.26%, FeSO 4 ·7H 2 O 20.8%, MnSO 4 1.1%, MgSO 4 1.2%, CaSO 4 ·H 2 O 1.2%, TiO 2 0.45%), the inlet temperature of the tower is 560°C, the outlet temperature is 103°C, the amount of evaporated water per hour is 63Kg, and 70Kg of concentrated sulfuric acid slurry is obtained per hour from the bottom of the tower (its main composition is: H 2 SO 4 42.29%, FeSO 4 ·H 2 O24.11%, MnSO 4 2.09%, MgSO 4 2.28%, CaSO 4 2.01%, TiO 2 0.85%); Afterwards, the concentrated sulfuric acid slurry was cooled to a temperature of 65°C, and vacuum filtration was carried out to obtain a wet cake of 33.83Kg per hour, and a filtrate of 36Kg (H 2 SO 4 59.21%, Fe 2 O 3 0.30%, MgO0.71%, Al 2 O3 0.43%, TiO2 0.06%).

Embodiment 2

[0035] Perform spray concentration and separation according to Example 1. After suction filtration, 33.83Kg of wet cake is washed with 22.26% dilute sulfuric acid 30Kg per hour to obtain 27.06Kg of wet cake (H2SO4 6.50%, H2O 18.5%), and 36.77Kg of the filtrate washing liquid containing 35.40% sulfuric acid, the washing liquid is returned to the spray concentration tower and combined with dilute sulfuric acid as a concentrated feed.

Embodiment 3

[0037] With coal-burning high-temperature gas, the specification is φ6×22m, and the volume is 600m 3 16.41t of dilute sulfuric acid per hour (its composition: H2SO4 23.16%; FeSO4·7H2O 17.6%; MnSO4 1.1%; MgSO4 1.3%; CaSO4·H2O 1.2%; TiO2 0.5%) is fed per hour into the spray concentration tower for spray countercurrent contact Heating and concentration; hot air enters the tower at 600℃, exits at 95℃, and evaporates 9.0t per hour to obtain concentrated dilute sulfuric acid 7.4t (the composition is: H2SO451.3%; FeSO4·H2O 23.8%; MnSO4 2.44%; MgSO4 2.88%; CaSO42.35%; TiO2 1.11%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com