Method for recovering refined bismuth from noble lead

A technology of precious lead and refined bismuth, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of unfavorable clean production and low-carbon economy, high comprehensive treatment cost, and lengthy process, and shorten the recycling cycle of bismuth metal , shorten the production cycle, good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

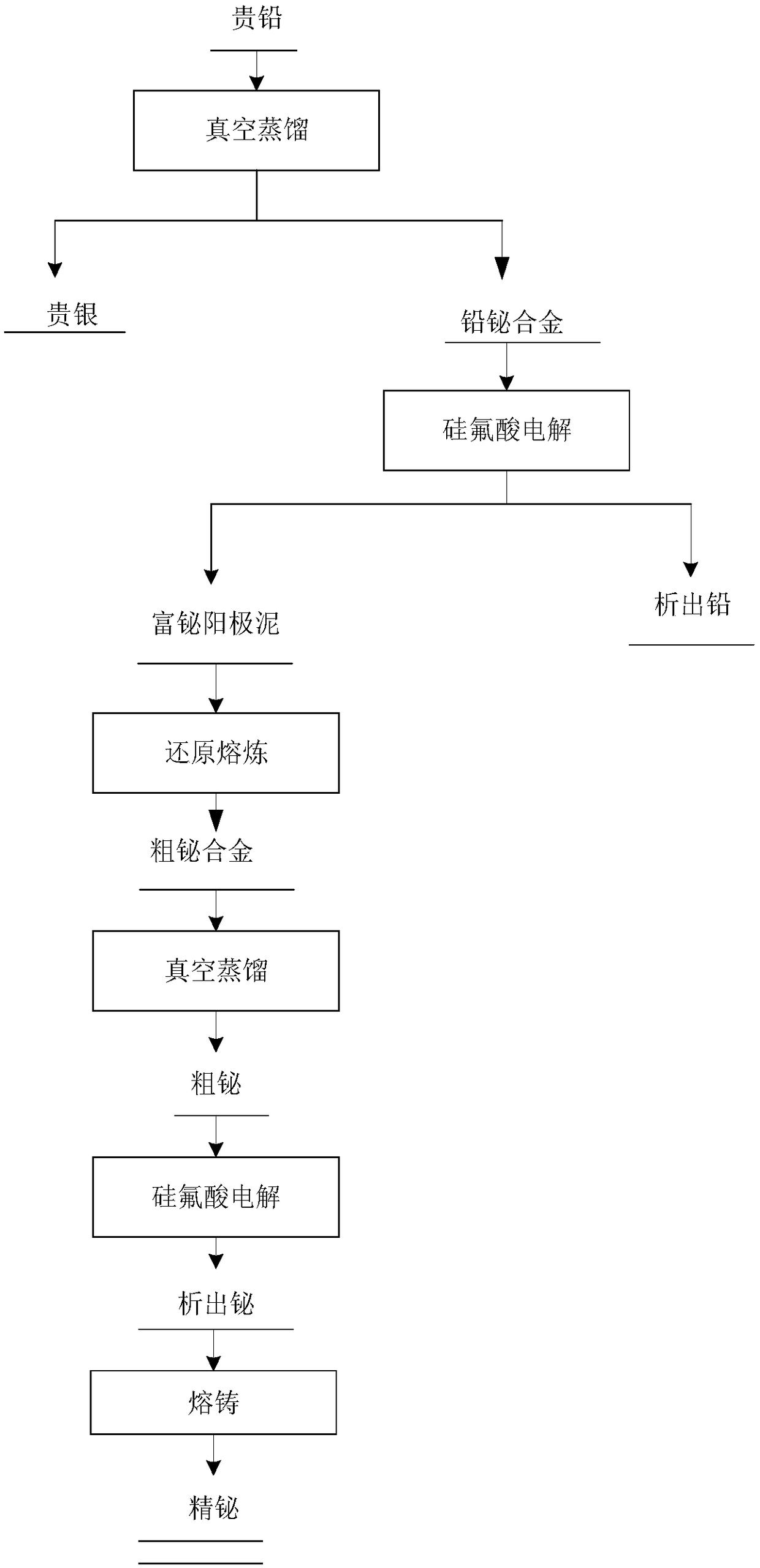

[0022] Such as figure 1 Shown, a kind of method for recovering refined bismuth from precious lead, comprises the following steps:

[0023] (1) First noble lead (Pb52.5wt%, Sb13.0wt%, Cu3.9wt%, Bi8.0wt%, Ag16.1wt%) is placed in a vacuum furnace, melted at a temperature of 465 ° C, and then controlled The vacuum degree is 15Pa, the temperature is 940 ℃, and the noble lead feeding amount is vacuum distillation 38min under the condition of 71g / s, separates lead, antimony, bismuth, copper, and produces lead-bismuth alloy (Pb79.5wt%, Bi10.0wt%, Sb6 .3wt%) and precious silver (Pb1.7wt%, Sb10.4wt%, Cu18.25wt%, Bi1.53wt%, Ag67.2wt%), precious silver is directly sent to silver converter to produce crude silver;

[0024] (2) The lead-bismuth alloy obtained is directly cast into bismuth anode plate I, and then electrolyzed separately under the silicofluoric acid system, obtains to separate out lead and rich bismuth anode slime (Pb7.8wt%, Sb14.2wt%, Bi40.2wt% %, Ag0.98wt%); wherein the e...

Embodiment 2

[0028] Such as figure 1 Shown, a kind of method for recovering refined bismuth from precious lead, comprises the following steps:

[0029] (1) At first noble lead (40.0wt%, Sb16.5wt%, Cu5wt%, Bi12.4wt%, Ag15.0wt%) is placed in the vacuum furnace, is melted under the condition of 450 ℃ at temperature, then controls vacuum degree to be 20Pa, temperature is 950 ℃, noble lead feed rate is vacuum distillation 35min under the condition of 69g / s, separates lead, antimony, bismuth, copper, produces lead-bismuth alloy (Pb70.0wt%, Sb8.7wt%, Bi16.7wt% , Ag0.25wt%) and precious silver, precious silver is directly sent to silver converter to produce crude silver;

[0030] (2) The lead-bismuth alloy that makes is directly cast into bismuth anode plate 1, then carries out electrolysis separately under silicofluoric acid system, obtains and separates out lead and rich bismuth anode slime (Pb6.4wt%, Sb13.3wt%, Bi42.5wt% %, Ag1.48wt%); wherein the electrolytic process parameters under the flu...

Embodiment 3

[0034] Such as figure 1 Shown, a kind of method for recovering refined bismuth from precious lead, comprises the following steps:

[0035] (1) First noble lead (Pb57.0wt%, Sb16.5wt%, Cu3.0wt%, Bi14.3wt%, Ag20.0wt%) is placed in a vacuum furnace, melted at a temperature of 480 ° C, and then controlled The vacuum degree is 10Pa, the temperature is 960 ℃, and the noble lead feed rate is vacuum distillation for 45min under the condition of 68g / s to separate lead, antimony, bismuth and copper, and produce lead-bismuth alloy (Pb81.1wt%, Sb12.2wt%, Bi17 .6wt%, Ag0.55wt%) and precious silver, precious silver is directly sent to silver converter to produce rough silver;

[0036] (2) The lead-bismuth alloy obtained is directly cast into bismuth anode plate I, and then mixed electrolysis is carried out together with the main process of lead electrolysis under the fluorosilicic acid system to obtain separated lead and bismuth-rich anode slime (Pb7.8wt%, Sb14 .2wt%, Bi40.2wt%, Ag0.98wt%)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com