Acid making system suitable for high-concentration sulfur dioxide-containing flue gas

A sulfur dioxide, high-concentration technology, applied in the field of acid production system, can solve the problems of increased investment, increased operating costs, unsuitable for expansion and transformation of flue gas acid production system, and achieves the goal of maintaining heat balance, saving equipment investment and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific embodiments.

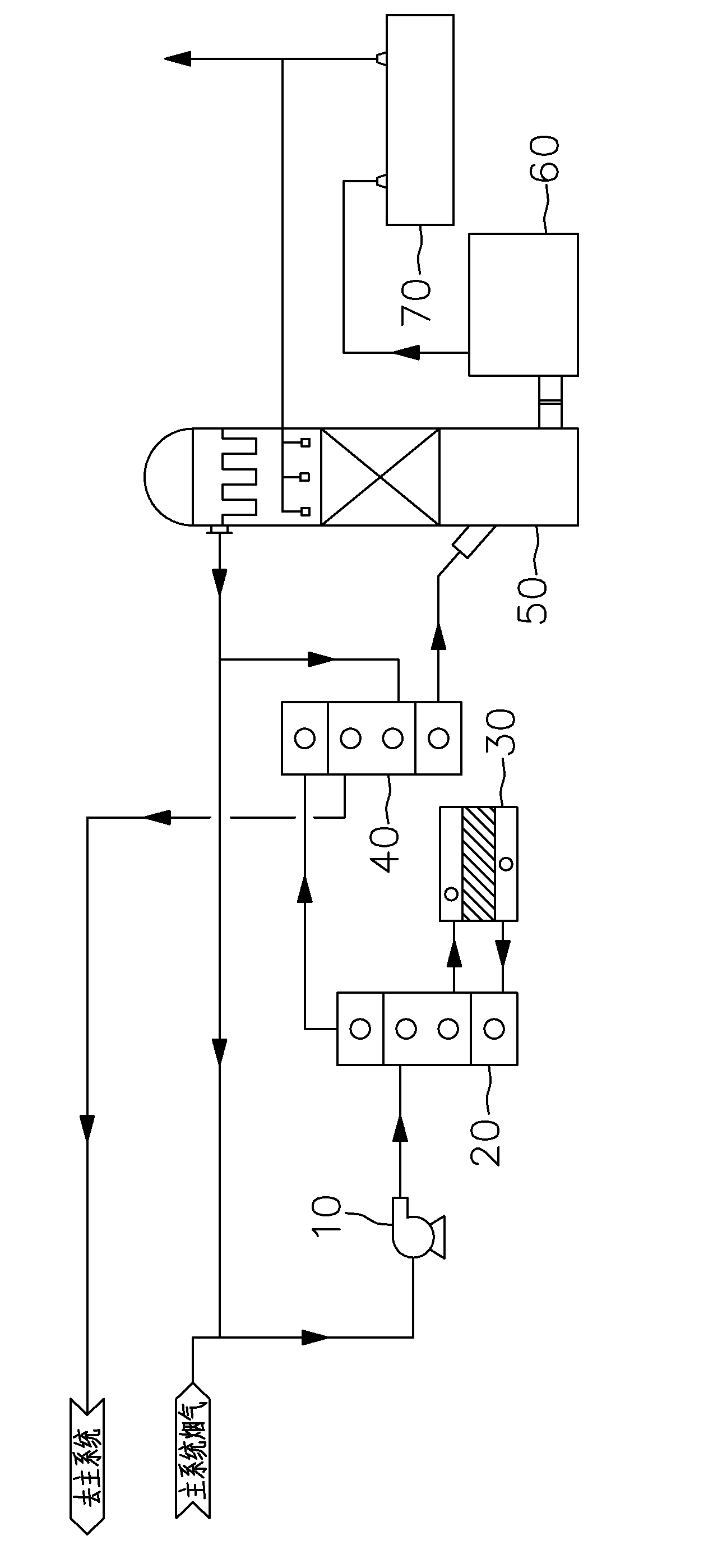

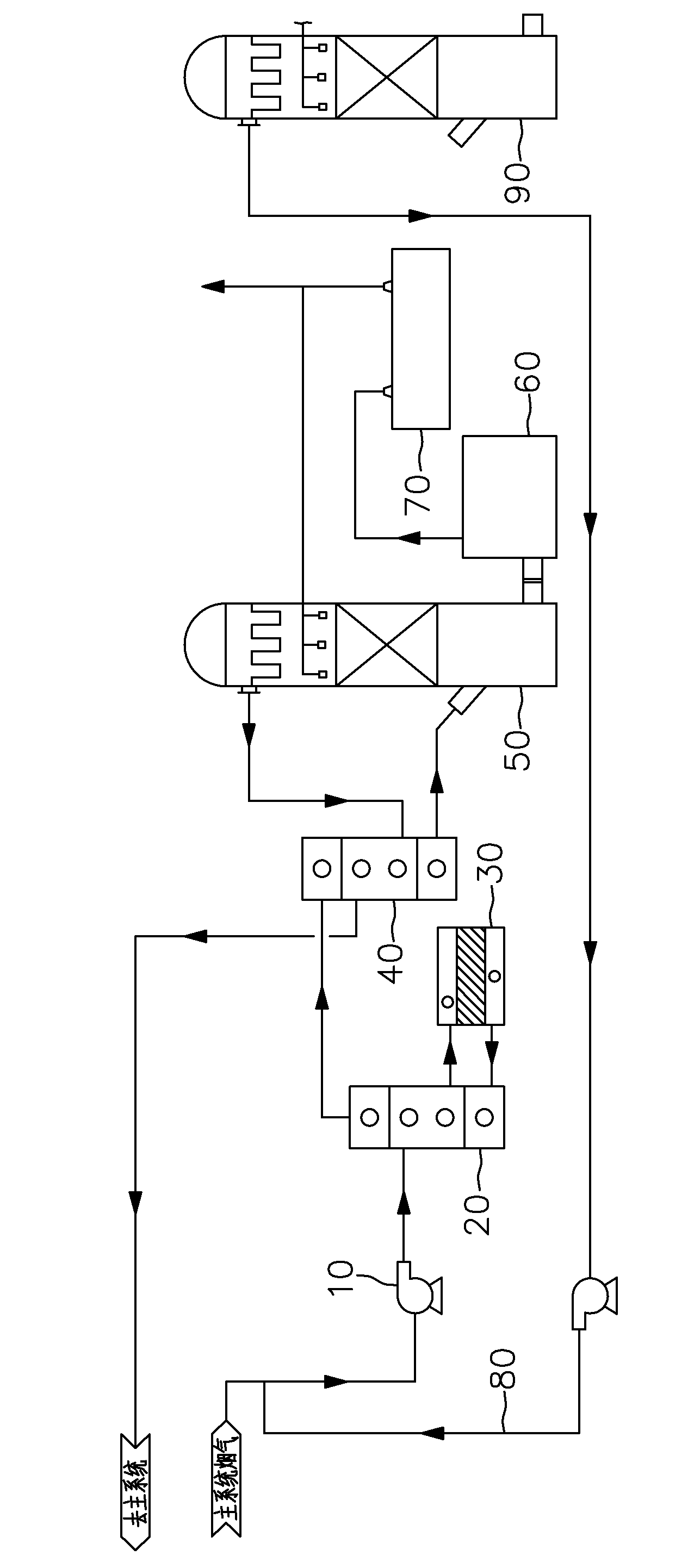

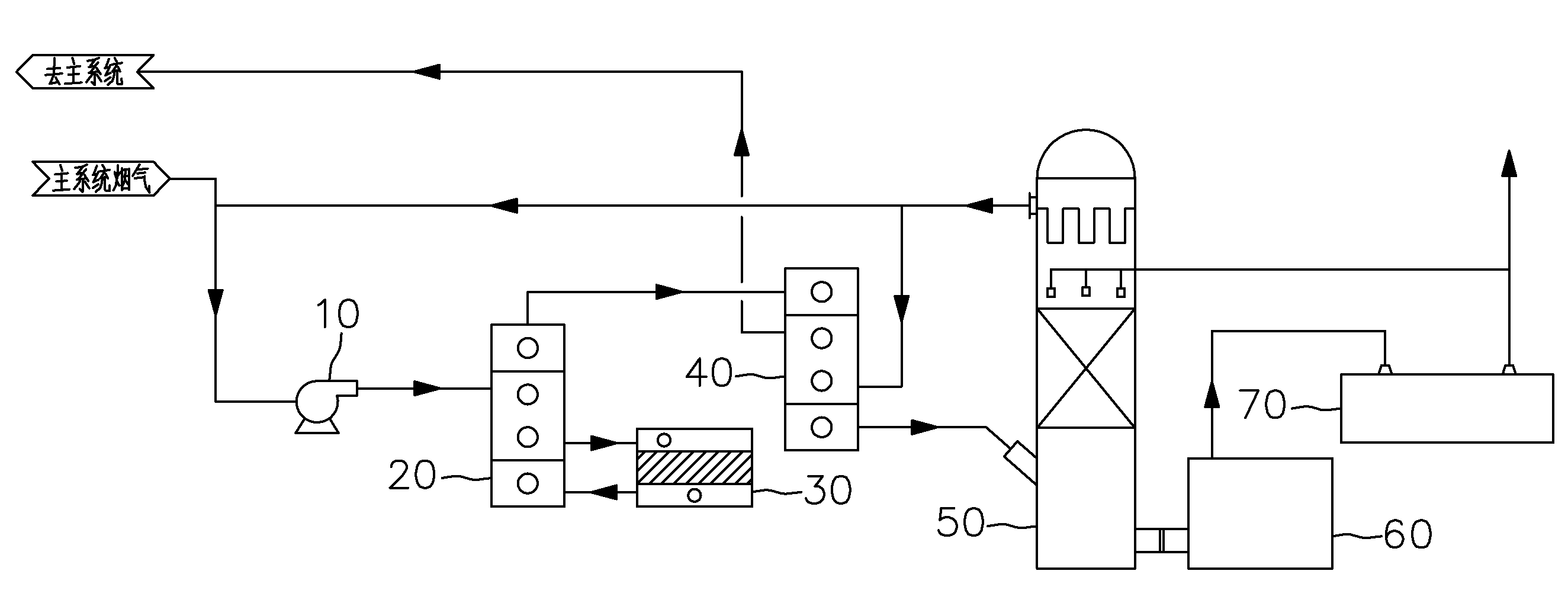

[0022] Such as figure 1 As shown, the SO imported from the main system 2 Flue gas with concentration higher than 13% and SO after pre-reforming and absorbing system treatment 2 Mix flue gas with a concentration lower than 13%, so that the SO of the mixed flue gas 2 If the concentration is lower than 13%, the mixed flue gas is pressurized by the pre-reformer fan 10, heated by the first heat exchanger 20, treated by the pre-reformer 30, heat-exchanged by the first heat exchanger 20 again, and secondly heat-exchanged by the second heat exchanger. heat exchange device 40, and finally enter the pre-absorption tower 50 for treatment to obtain SO 2 The flue gas whose concentration is lower than 13%, the flue gas treated by the pre-absorption tower 50 is divided into two paths, one of which passes through the second exchanger 40 to exchange heat with the SO2 that is ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com