Regeneration method for alkylated waste sulfuric acid

A technology for alkylating waste sulfuric acid and waste sulfuric acid, applied in sulfur trioxide/sulfuric acid, chemical instruments and methods, chemical recovery, etc., can solve the problems of combustion boiler system corrosion, high maintenance cost of equipment, complicated process, etc. Low operating energy consumption, low device maintenance cost, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

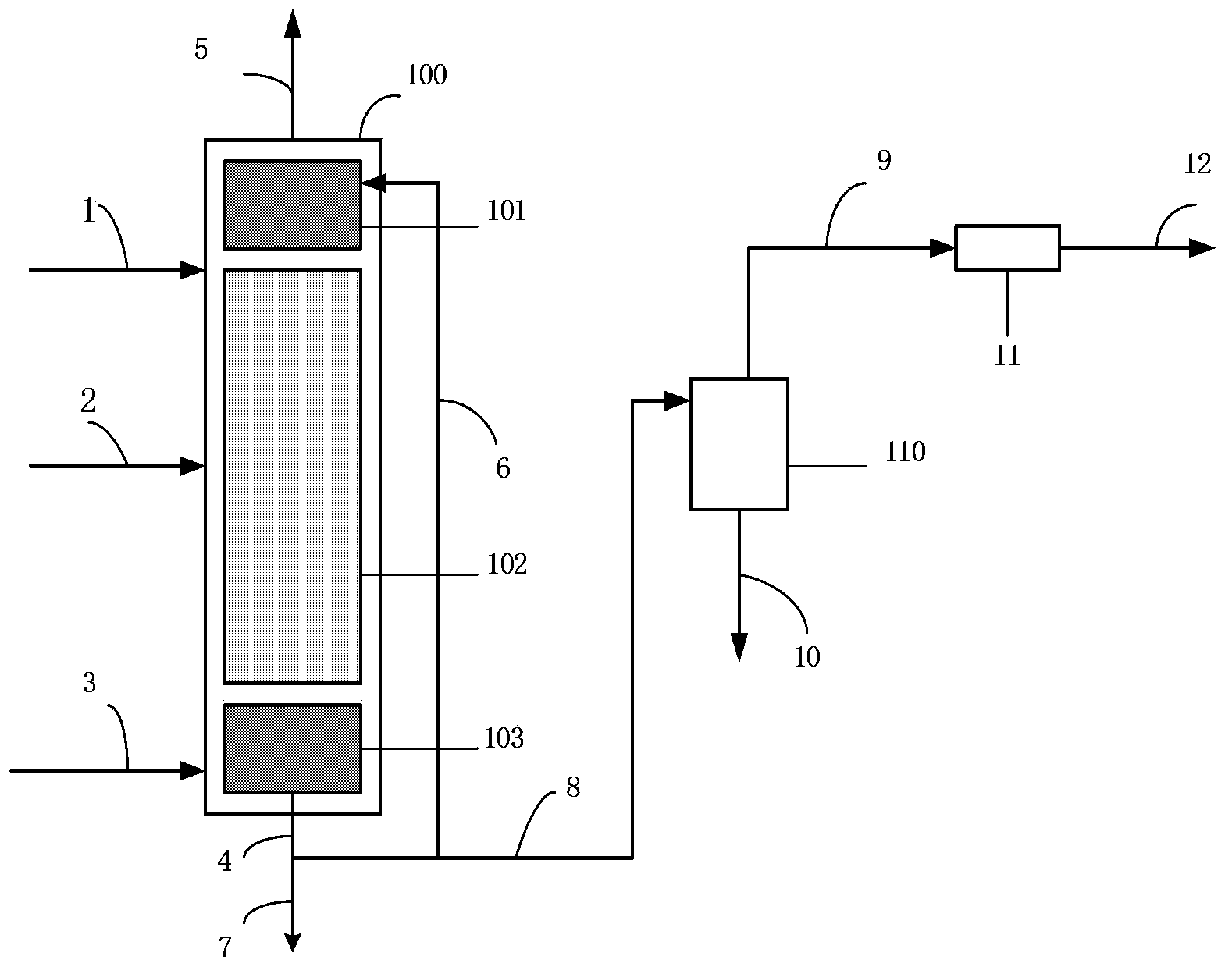

[0020] A kind of method of regeneration alkylation waste sulfuric acid provided by the invention is specifically implemented like this:

[0021] A method for regeneration of alkylated waste sulfuric acid, characterized in that under redox conditions, waste sulfuric acid is contacted with an oxidation aid, and organic matter or tiny carbon particles in the waste sulfuric acid react with an oxidant to be converted into CO 2 , N 2 、H 2 O, after being removed by stripping, regenerated sulfuric acid is obtained.

[0022] In the method provided by the invention, the oxidizing agent is selected from H 2 o 2 , O 3 、HNO 3 and a mixture of one or more of NOx. The oxidizing agent preferably adopts HNO 3 , more preferably HNO with a mass percent concentration of 65wt% 3 .

[0023] In the method provided by the present invention, the oxidation aid is selected from one or more of aluminum silicate, silicon dioxide and alumina pellets.

[0024] In the method provided by the inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com