Treatment and recovery process of acid wastewater in titanium dioxide production process

A technology of acid wastewater and production process, applied in the direction of osmosis/dialysis water/sewage treatment, titanium dioxide, sulfur trioxide/sulfuric acid, etc., can solve problems such as ineffective utilization, large gypsum slag, secondary pollution, etc., and achieve easy management, Reduced emissions and ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

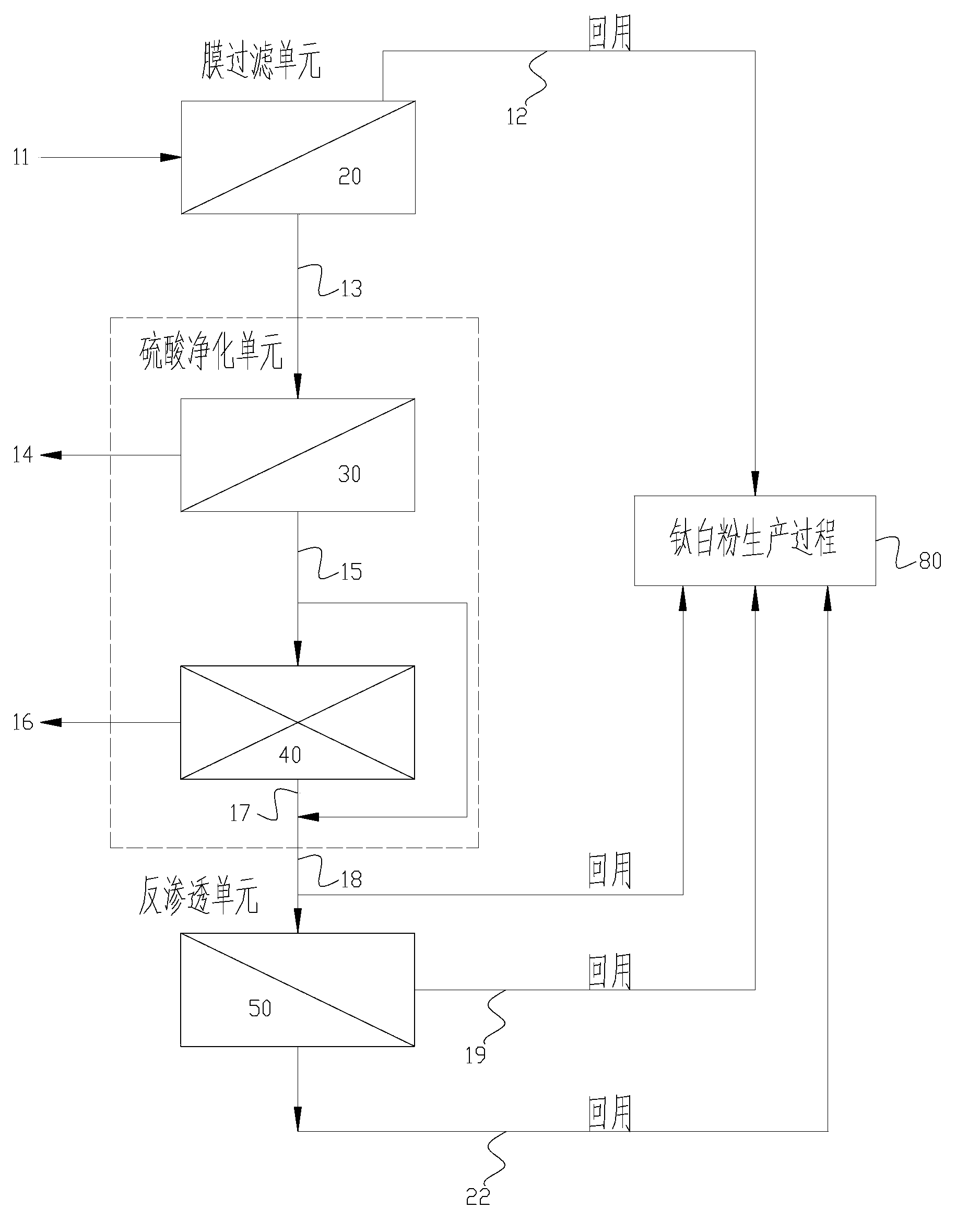

[0053] 100m 3 The mixed acid wastewater is collected into the intake tank. It is pumped into the membrane filtration unit device. Driven by the operating pressure of 0.3-0.7MPa, water, sulfuric acid, ferrous sulfate, and other dissolved substances permeate the membrane to become membrane permeate. Suspended solids, undissolved particles and other substances that cannot pass through the membrane are retained. As the filtration proceeds, the insoluble particles are gradually concentrated and enriched. When the concentration ratio reaches 25 times, the concentrated solution is collected, and 99.5% of the metatitanic acid is intercepted and concentrated.

[0054] The intercepted suspended matter is mainly titanium dioxide hydrate (metatitanic acid). The enriched titanium dioxide returns to the controlled filtration section after hydrolysis to recover metatitanic acid particles, thereby increasing the yield of metatitanic acid. The above process only has a concentration proces...

Embodiment 2

[0061] 100m 3 The mixed acid wastewater is collected into the intake tank. It is pumped into the membrane filtration unit device. Driven by the operating pressure of 0.3-0.7MPa, water, sulfuric acid, ferrous sulfate, and other dissolved substances permeate the membrane to become membrane permeate. Suspended solids, undissolved particles and other substances that cannot pass through the membrane are retained. As the filtration proceeds, the insoluble particles are gradually concentrated and enriched. When the concentration ratio reaches 25 times, the concentrated solution is collected, and 99.5% of the metatitanic acid is intercepted and concentrated.

[0062] The intercepted suspended matter is mainly titanium dioxide hydrate (metatitanic acid). The enriched titanium dioxide returns to the controlled filtration section after hydrolysis to recover metatitanic acid particles, thereby increasing the yield of metatitanic acid. Membrane filtration unit intercepts concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com