Method for treating waste acid produced from titanium dioxide production using vitriol method

A titanium dioxide, sulfuric acid method, applied in sulfur trioxide/sulfuric acid, osmosis/dialysis water/sewage treatment, etc., can solve the problems of low utilization of permeate, high energy consumption, waste of acid resources, etc., and achieve recovery rate The effect of high, high purity and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

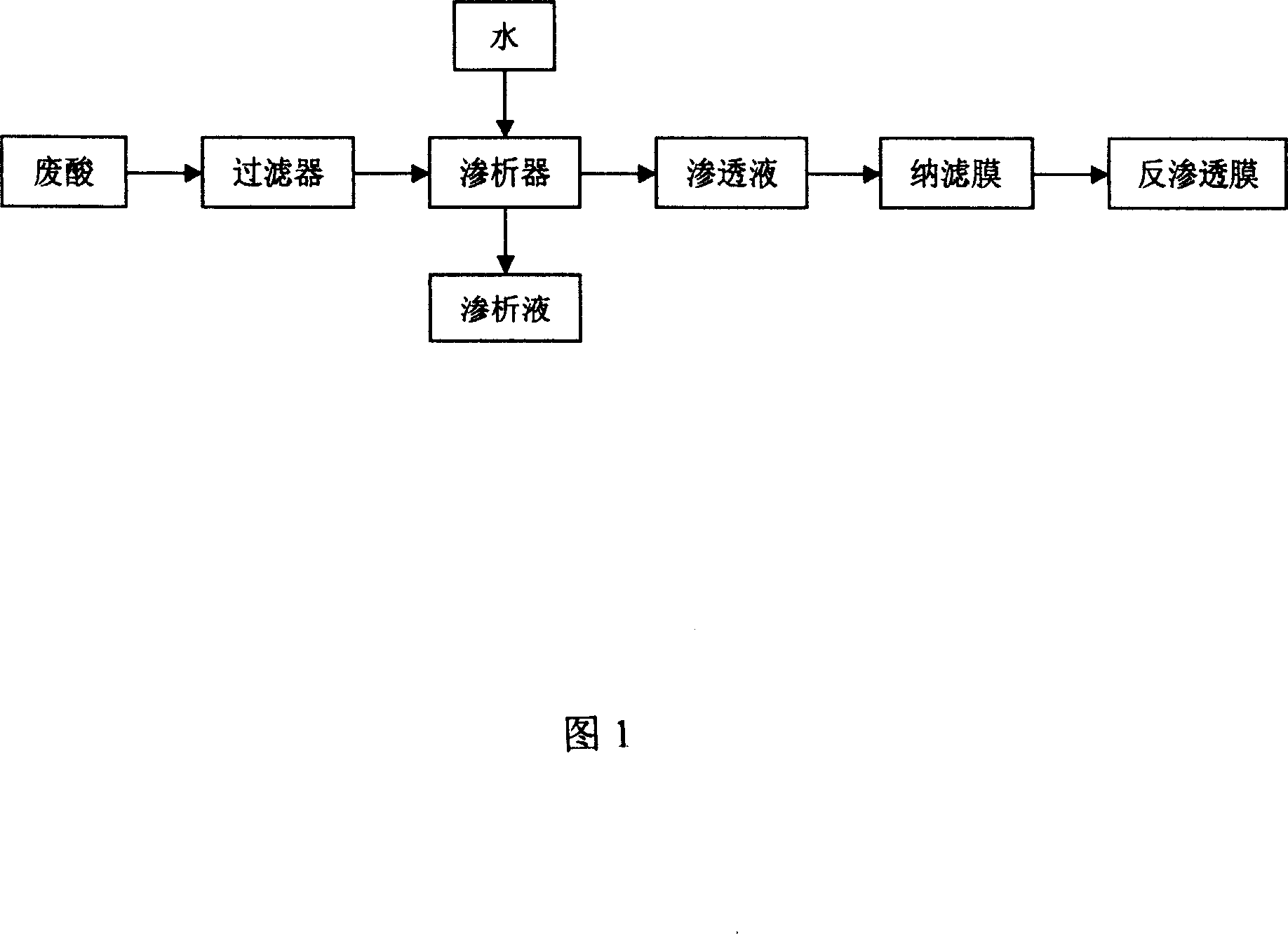

[0013] As shown in Figure 1, it is a schematic diagram of the process flow of the present invention, a method of producing waste acid in the process of producing titanium dioxide by sulfuric acid process, which is to filter and dialysis the waste acid produced in the process of producing titanium dioxide by sulfuric acid process, and the dialysate Through nanofiltration, then enter the subsequent reverse osmosis process for concentration, the method is:

[0014] Step 1. Put the waste acid into a 5um precision filter through a high-pressure corrosion-resistant pump for filtration, the filtrate enters the container, and the filter residue is returned to the titanium dioxide production process for reuse;

[0015] The second step. The tap water and the filtered waste acid enter the two inlets of the diffusion dialyzer respectively, and the flow rate is controlled to 0.01m 3 / d, make the residence time 8-12 hours, carry out sulfuric acid H 2 SO 4 and ferrous sulfate FeSO 4 The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com