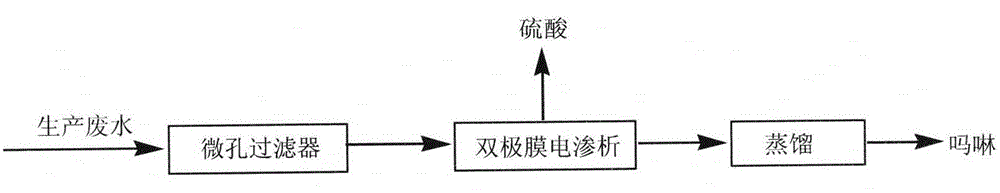

Method for bipolar membrane electrodialysis treatment of 3-aminopyrazole-4-carboxamide hemisulfate production wastewater and recycling of sulfuric acid

A bipolar membrane electrodialysis and aminopyrazole technology, which is applied to membrane separation technology in the field of wastewater recycling, can solve the problems of low purity of sodium sulfate, environmental pollution, and high requirements for anticorrosion of distillation towers, so as to reduce resource consumption and improve environmental pollution. , the effect of significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

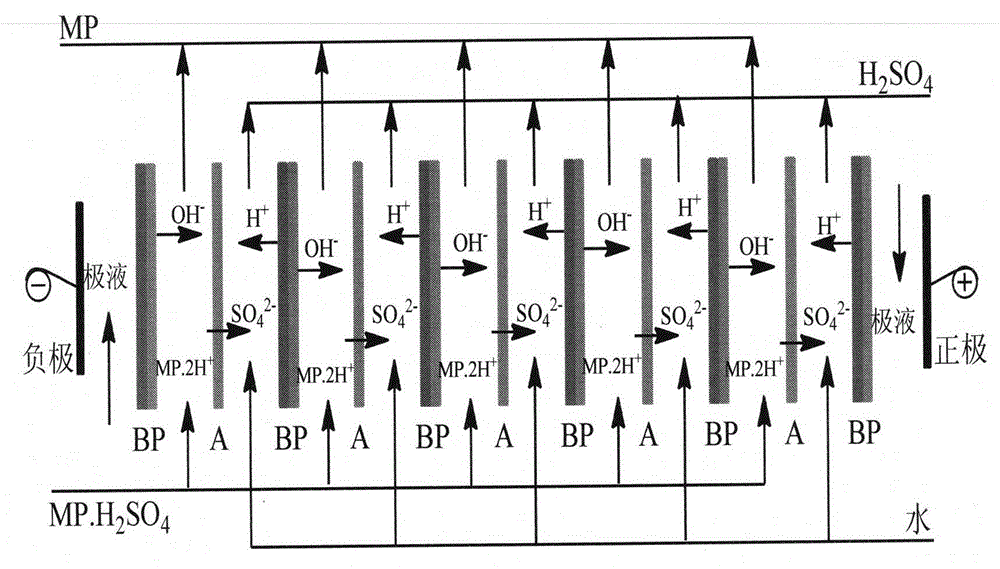

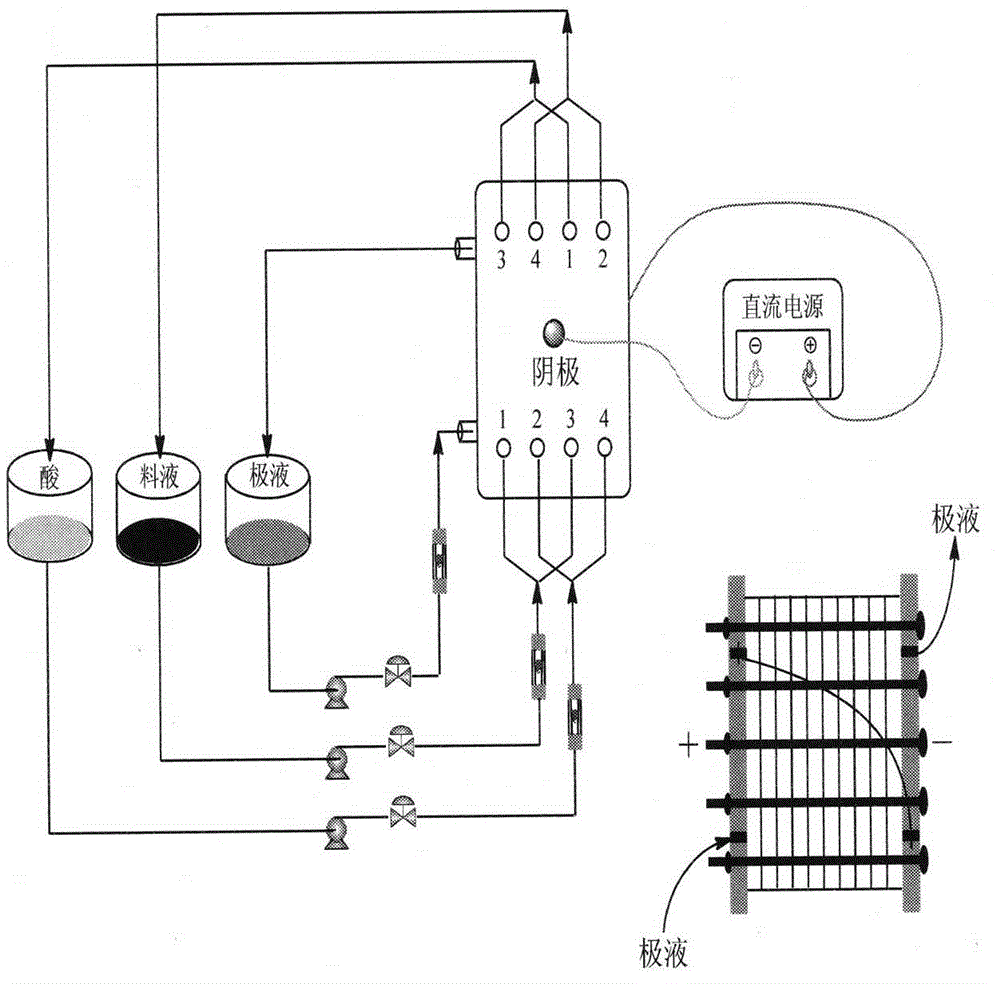

Embodiment 1

[0018] 5L of 3-aminopyrazole-4-carboxamide hemisulfate production wastewater is filtered through a cartridge filter with a filtration accuracy of 0.45 microns to remove particulate impurities and suspended solids present therein. The conductivity of the filtered wastewater is 48.9ms / cm, and the pH value is 2.32. 10 sets of 20cm*40cm bipolar membrane-cathode membrane 1-cathode membrane 2 three-compartment membrane stack are used. Both the cathode and the anode use titanium-coated ruthenium electrodes. clapboard. The filtered wastewater is pumped into the salt chamber / alkali chamber of the bipolar membrane. The compartment between the negative membrane 1 and the negative membrane 2 is called the intermediate chamber. The mass fraction of the pump is 0.1% dilute sulfuric acid, and the acid chamber of the membrane stack is the same Pump in 0.1% dilute sulfuric acid, the polar solution is 3% sodium sulfate solution, connect the cathode and anode of the device to the negative and p...

Embodiment 2

[0020] 1L of 3-aminopyrazole-4-carboxamide hemisulfate production wastewater is filtered through a cartridge filter with a filtration accuracy of 0.45 microns to remove particulate impurities and suspended solids present therein. The conductivity of the filtered wastewater is 48.9ms / cm, and the pH value is 2.32. 10 groups of 11cm*27cm bipolar membrane-cathode membrane two-compartment membrane stack are used. Both the cathode and the anode use titanium-coated ruthenium electrodes. Pump the pretreated wastewater into the salt chamber / alkali chamber of the bipolar membrane, pump 0.1% dilute sulfuric acid into the acid chamber, and 3% sodium sulfate solution as the polar liquid, and control the current density of its DC electric field to 30mA / cm 2 , the temperature is 25°C, and the bipolar membrane electrodialysis equipment is started, and the sulfuric acid with a concentration of 4.3% is recovered through the bipolar membrane electrodialysis treatment, and the deacidified wastewa...

Embodiment 3

[0022] Five groups of 11cm*27cm bipolar membrane-cathode membrane-positive membrane-bipolar membrane three-compartment membrane stack are used. Both the cathode and the anode use titanium-coated ruthenium electrodes, and the separator adopts 3 layers of anti-leakage and Elastic partition that leaks inside and outside. Pump 500ml of pretreated wastewater into the salt chamber of the bipolar membrane stack, pump 0.1% dilute sulfuric acid into the acid chamber of the membrane stack, and pump purified water or 0.1% morpholine aqueous solution into the alkali chamber of the membrane stack, The polar liquid is 1% sulfuric acid solution, and the current density of its DC electric field is controlled to be 25mA / cm 2 , the temperature is 25°C, start the bipolar membrane electrodialysis equipment, and recover the sulfuric acid with a concentration of 4% after the bipolar membrane electrodialysis treatment, and obtain morpholine by distillation and separation from the deacidified wastewa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com