Production process of biomass pellet fuel and complete equipment

A technology of biomass pellets and complete sets of equipment, applied in the directions of biofuels and waste fuels, can solve the problems of inconvenient transportation and storage, low production efficiency, and low particle density, and achieve convenient transportation and storage, high production efficiency, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

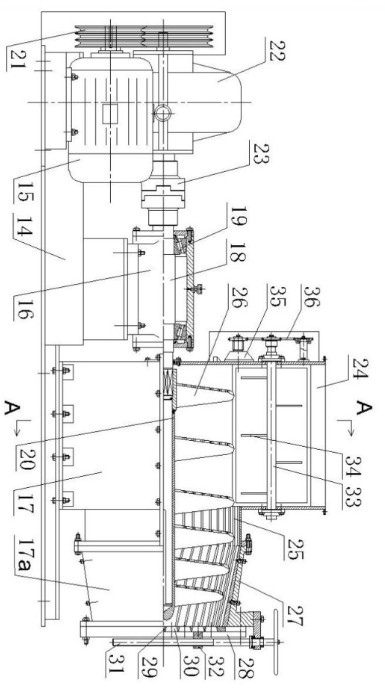

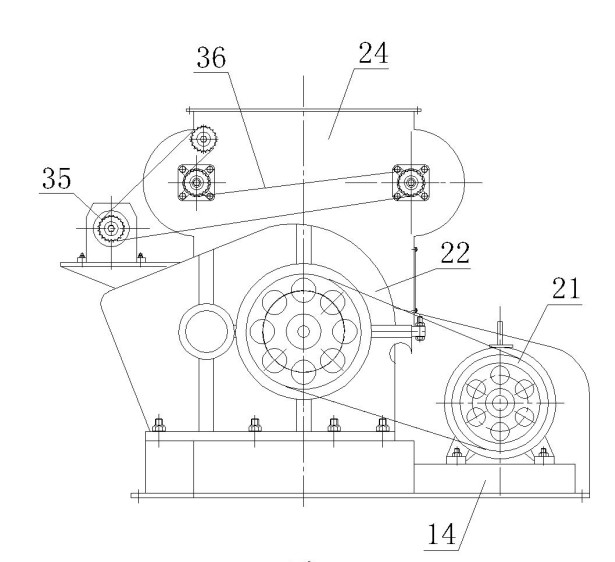

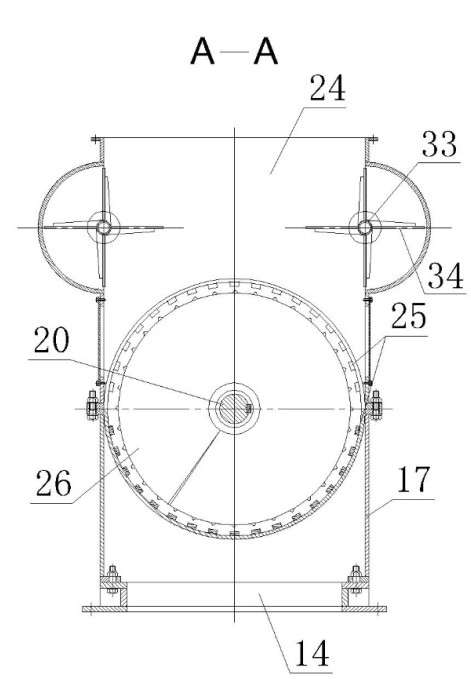

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the complete set of equipment for the production of biomass pellet fuel of the present invention includes a biomass crusher 1, a tempering and curing machine 2, a flue gas drying mixer 3, a forming extruder 4, and an air-cooled dryer 5 arranged in sequence. There is a belt feeder between two adjacent machines arranged in sequence, and a collection bin 7 is also provided on the belt feeder 6 between the biomass crusher 1 and the quenching and tempering ripening machine 2, and a cyclone dust collector 8 passes through the pipe The road is connected with the collection bin 7, and a magnet 10 is also provided through the support above the belt feeder 9 between the flue gas drying mixer 3 and the forming extruder 4, and a hot blast stove 11 is respectively connected to the flue gas drying mixer 3 and the flue gas drying mixer 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com