Biomass pellet fuel forming machine

A technology of biomass granules and molding machines, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of low utilization rate, air pollution, etc., and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

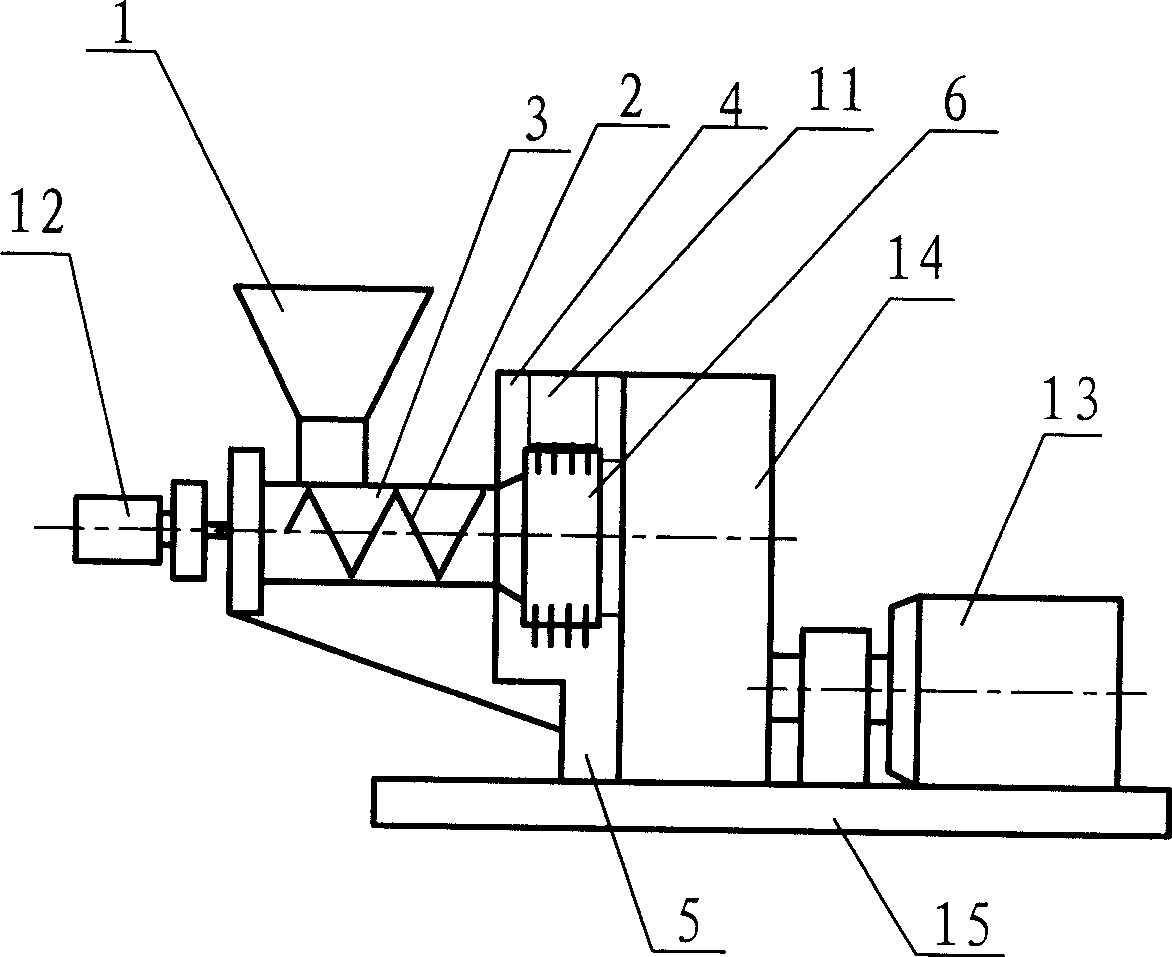

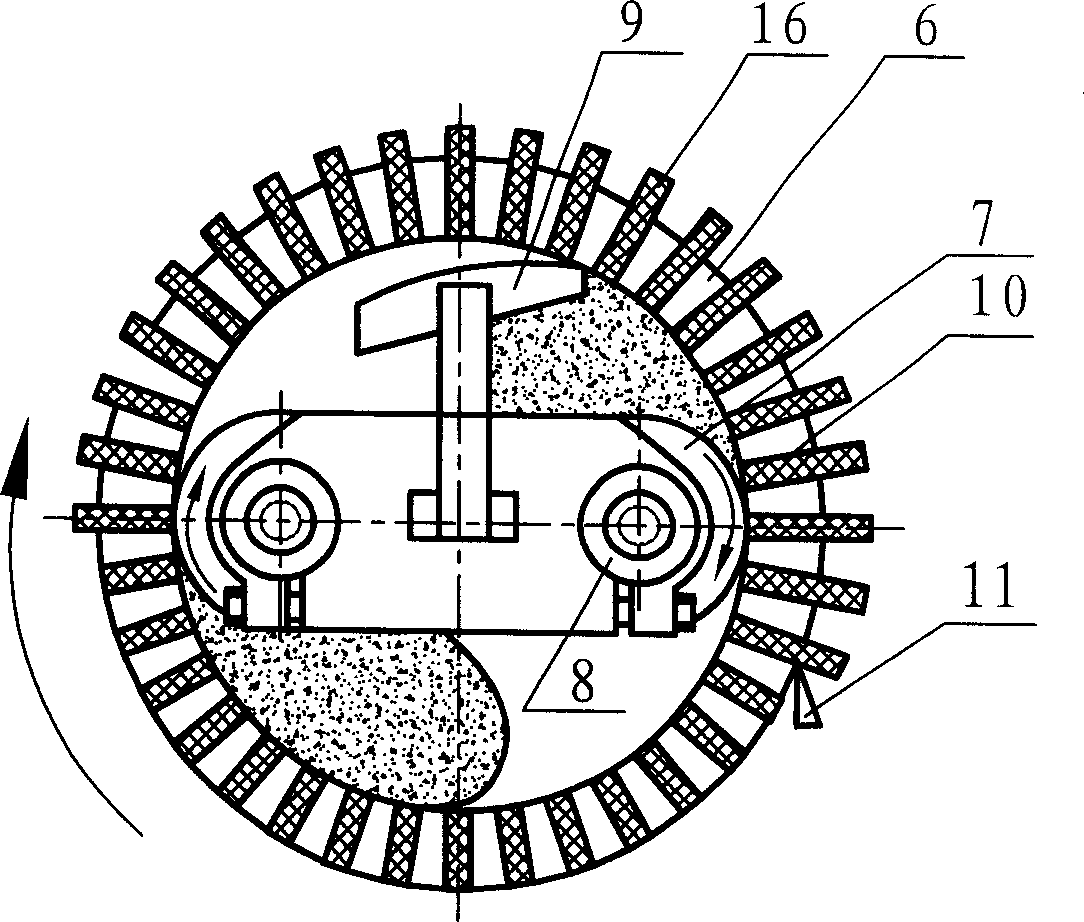

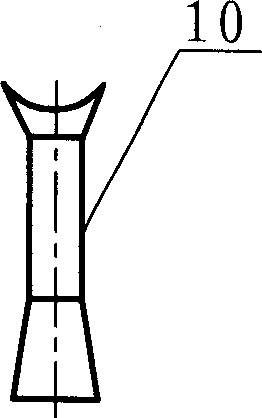

[0013] Biomass pellet fuel molding machine, including a feed hopper 1, the feed hopper 1 outlet is connected to the feed chamber 3 with the feed auger 2 installed, the feed chamber 3 outlet is connected to the granulation chamber 4, and the granulation chamber 4 is installed with The lower part of the granulation mechanism and the granulation chamber 4 is provided with a discharge port 5 . The granulation mechanism includes an annular die 6 with a closed outer end and two pressure rollers 7 arranged radially in the middle and pressing against it. The pressure rollers 7 are installed on the pressure roller bearing 8, and the feed end of the annular die 6 is provided with a The feed cover 9 is provided with a bulk material plate 23, and the annular die 6 is provided with a radial forming hole 10, and the inner and outer ends of the forming hole 10 are tapered. In the granulation chamber 4, a cutter 11 is installed on the outside of the annular die 6 in contact with its surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com