Esomeprazole medicated pellet and preparing method thereof

A technology for esomeprazole and pellets, which is applied in the field of esomeprazole drug-containing pellet intermediates and the preparation field thereof, can solve the problem of large drug-loading capacity, waste of time, manpower and difficulty in mixing and granulating in a coating pan. Material resources, low production efficiency, etc., to achieve significant economic benefits, improve efficiency, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

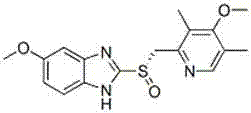

Image

Examples

Embodiment 1

[0030] The esomeprazole drug-containing pellets of the present invention are mainly composed of 175g (mass percentage of 41.7%) of raw materials esomeprazole, 145g of mannitol (34.5% of mass percentage) and 100g of crospovidone (mass percentage is 23.8%); in addition, 150g of binder purified water (accounting for 35.7% of the total weight of the three main raw materials) is added.

[0031] Explanation: The purified water added in this example goes through the preparation method and is finally dried to obtain the product, and all the added purified water evaporates; therefore, the main raw materials in this example are composed of esomeprazole, mannitol and crospovidone.

[0032] The preparation method of esomeprazole drug-containing pellet of the present invention, its detailed steps are as follows:

[0033] a. First, the raw materials esomeprazole, crospovidone and mannitol are crushed through a 80-mesh sieve, sieved and placed in a stirring mixer to mix evenly. After mixing ...

Embodiment 2

[0035] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0036]The esomeprazole drug-containing pellets of the present invention mainly consist of raw materials esomeprazole 145g (mass percentage is 34.5%), mannitol 173g (mass percentage is 41.2%) and crospovidone 102g (mass percentage is 24.3%); in addition, 165g of binder purified water (accounting for 39.3% of the total weight of the three main raw materials) is added.

[0037] Explanation: The purified water added in this example goes through the preparation method and is finally dried to obtain the product, and all the added purified water evaporates; therefore, the main raw materials in this example are composed of esomeprazole, mannitol and crospovidone.

[0038] The preparation method of the esomeprazole drug-containing pellets of the present invention is the same as in Example 1.

Embodiment 3

[0039] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0040] The esomeprazole drug-containing pellets of the present invention mainly consist of raw materials esomeprazole 110g (mass percentage is 26.2%), mannitol 210g (mass percentage is 50%) and crospovidone 100g (mass percentage is 23.8%); in addition, 146g of binder purified water (accounting for 34.8% of the total weight of the three main raw materials) is added.

[0041] Explanation: The purified water added in this example goes through the preparation method and is finally dried to obtain the product, and all the added purified water evaporates; therefore, the main raw materials in this example are composed of esomeprazole, mannitol and crospovidone.

[0042] The preparation method of the esomeprazole drug-containing pellets of the present invention is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com