Pelleting device for processing food

A technology of food processing and equipment, which is applied in the field of pill making equipment, can solve problems such as adhesion, different product shapes, and difficulty in cleaning, and achieve the effects of improved quality, reasonable design, and high rounding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

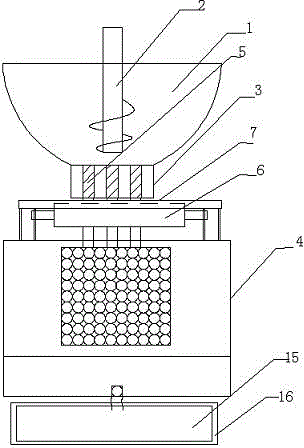

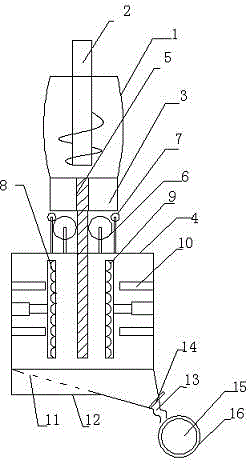

[0016] Such as Figure 1-2 As shown, the present invention is a kind of pelletizing equipment for food processing. The equipment includes a feed hopper 1. A stirring shaft 2 driven by a motor is inserted into the feed hopper 1. After passing through the stirring shaft first, the material is After stirring, the material is extruded by the blades or blades at the lower end of the stirring shaft 2, and a forming plate 3 with several cylindrical holes 5 is arranged below the feed hopper 1, and the forming plate 3 The several cylindrical holes 5 on the top are all arranged in parallel, and the parallel arrangement facilitates the extrusion of the left and right circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com