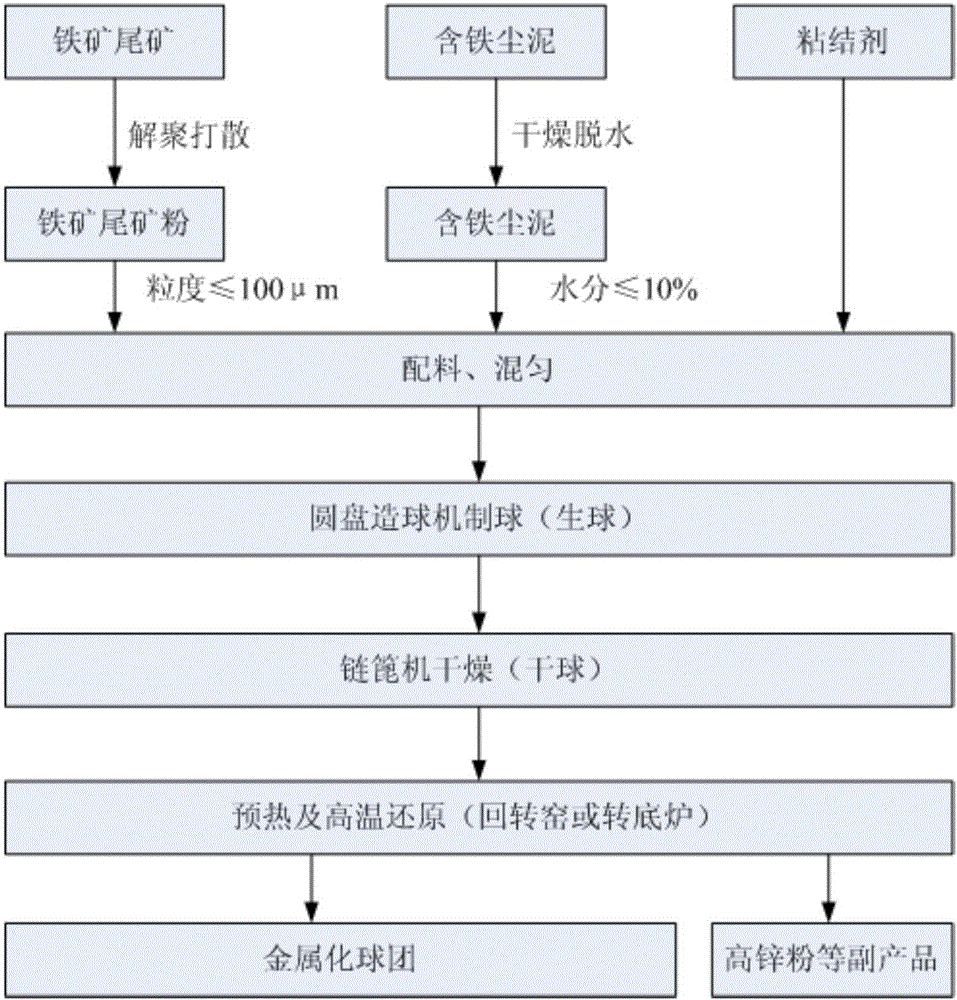

Method for producing metallized pellets through iron mine tailings

A technology for metallizing pellets and iron ore tailings is applied in the field of comprehensive utilization of resources to achieve the effects of improving resource utilization efficiency, improving pelletizing performance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The iron ore tailings are crushed and dispersed by a powder depolymerization and dispersing machine, and the particle size of the iron ore tailings after disintegration is ≤100 μm; the electric furnace ash, blast furnace trough dedusting ash, blast furnace casting house dedusting ash, and blast furnace sludge Mix with converter sludge at a ratio of 15:30:20:30:5 to obtain iron-containing dust-sludge mixture. The content of TFe in the mixture is 44.25%, the content of C is 13.90%, and C / O=1.0. The dryer dries the iron-containing dust and mud; mix the iron ore tailings and the iron-containing dust and mud mixture at a ratio of 10:90, add 4% bentonite, add water, fully mix with a strong mixer, and pass through the circular The disc pelletizer produces green pellets with a particle size of 10-16mm and a moisture content of 15%. The pellets are sent to the grate machine and dried at 500°C for 40 minutes to obtain dry pellets, which are then passed through a rotary kiln or Th...

Embodiment 2

[0030] The iron ore tailings are crushed and dispersed by a powder depolymerization and dispersing machine, and the particle size of the iron ore tailings after disintegration is ≤100 μm; the electric furnace ash, blast furnace trough dedusting ash, blast furnace casting house dedusting ash, and blast furnace sludge Mix with converter sludge at a ratio of 10:40:10:30:10 to obtain iron-containing dust-sludge mixture. The content of TFe in the mixture is 44.71%, the content of C is 15.88%, and C / O=1.15. The dryer dries the iron-containing dust and sludge; mix the iron ore tailings and the iron-containing dust and sludge mixture in a ratio of 30:70, add 1% bentonite and 5% coking dust, add water, and use strong mixing The machine is fully mixed, and the disc pelletizer is used to make green pellets with a particle size of 10-16mm. The water content of the pellets is 13%. The balls are then preheated and reduced at high temperature through a rotary kiln or a rotary hearth furnace....

Embodiment 3

[0032] The iron ore tailings are crushed and dispersed by a powder depolymerization and dispersing machine, and the particle size of the iron ore tailings after disintegration is ≤100 μm; the electric furnace ash, blast furnace trough dedusting ash, blast furnace casting house dedusting ash, and blast furnace sludge Mix with converter sludge at a ratio of 10:40:10:30:10 to obtain iron-containing dust-sludge mixture. The content of TFe in the mixture is 44.71%, the content of C is 15.88%, and C / O=1.15. The dryer dries the iron-containing dust and sludge; mix the iron ore tailings and the iron-containing dust and sludge mixture at a ratio of 30:70, add 1% bentonite and 4.5% coal powder, add water, and use a strong mixer Mix well, and use a disc pelletizer to make green pellets with a particle size of 10-16mm. The water content of the raw pellets is 13%. The pellets are sent to the grate machine and dried at 400°C for 30 minutes to obtain dry pellets. , and then preheat and high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com