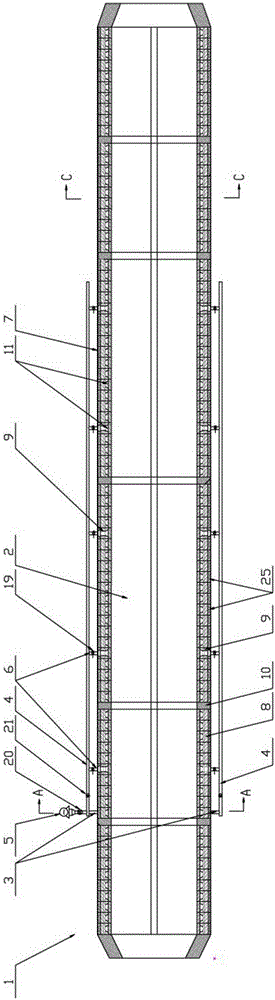

Method for directly reducing and producing metallized pellets by utilizing sensible heat of high-temperature oxidized pellets

A technology for metallizing pellets and oxidizing pellets, applied in the field of metallurgy, can solve the problems of reducing energy consumption and production costs, long reduction time, large investment scale, etc. The effect of emissions

- Summary

- Abstract

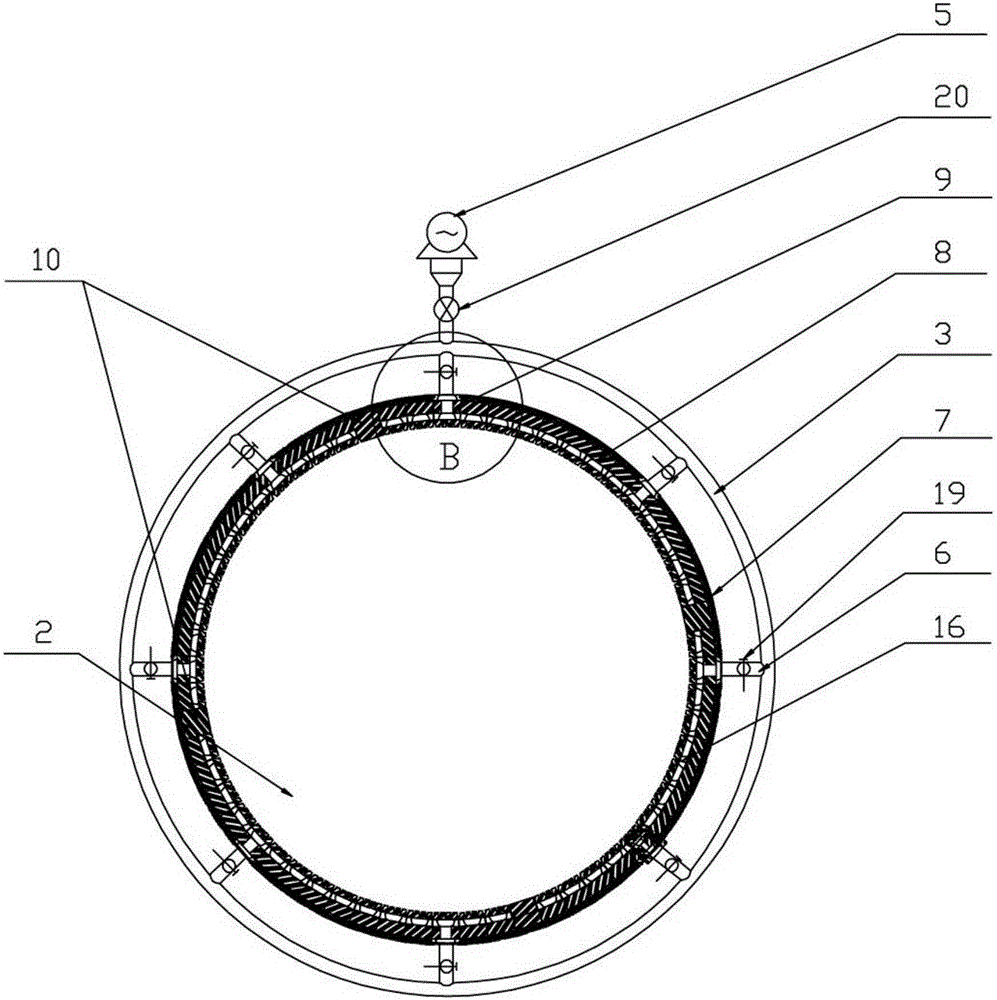

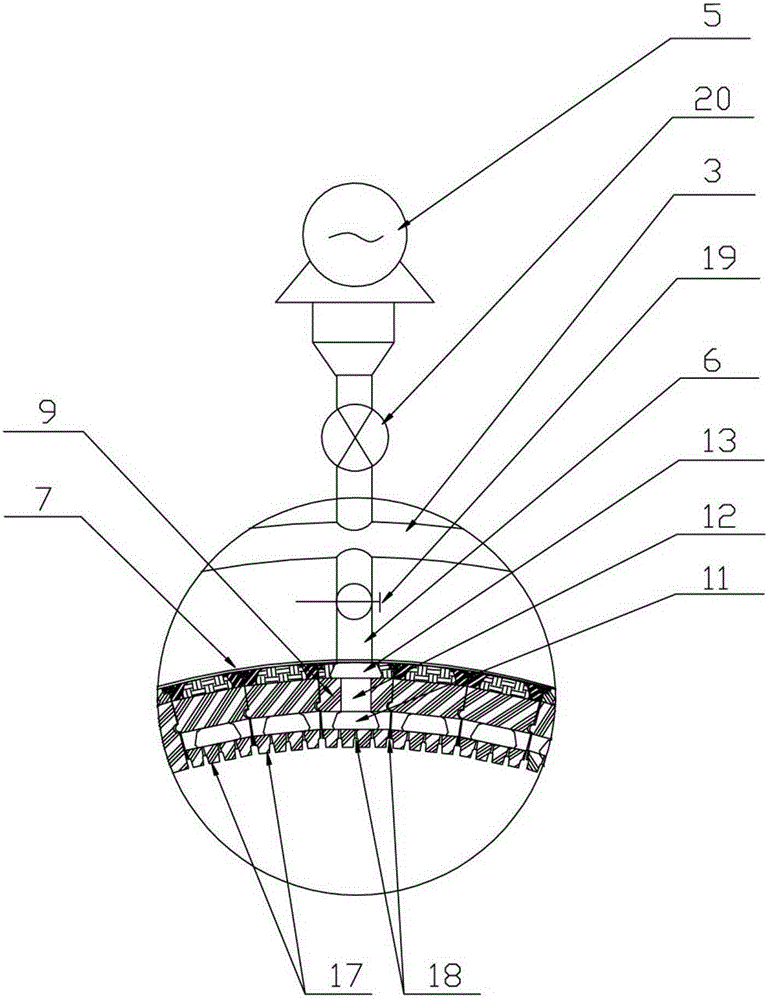

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for producing metallized pellets by direct reduction of sensible heat of high-temperature oxidation pellets, the steps are as follows:

[0055] (1) Take the magnetite powder of Liaoning Chaoyang grade TFe: 68.2% with a fineness of -200 mesh accounting for 80%, mix with sodium humate adding 2.0% of iron ore powder weight, moisten and grind, pelletize, and pelletize the particle size ¢8~¢16mm, dried in a muffle furnace at 105°C for 4 hours, rapidly raised to 1200°C in an oxidized pellet rotary kiln, and continued sintering for 18 minutes to obtain 1200°C high-temperature oxidized pellets;

[0056] (2) get the high-temperature oxidation pellet of step (1), add the anthracite of high-temperature oxidation pellet weight 45%, particle size 0-15mm (its chemical composition is that fixed carbon is 69.12%, ash content is 15.14% by mass percentage, Volatile content is 12.6%, S is 2.14%), after mixing, preheat at 800°C for 20 minutes, add to the flame-insulated deep reduc...

Embodiment 2

[0058] A method for producing metallized pellets by direct reduction of sensible heat of high-temperature oxidation pellets, the steps are as follows:

[0059] (1) get fineness and be that -200 orders account for more than 80% iron ore powder of grade TFe:69.21% in Yanji City, Jilin Province, add anthracite coal, 2% water-soluble polyvinyl alcohol fine powder of iron ore powder weight 5%, Uniformly mixed and milled, water sprayed into pellets, the pellet size is ¢8~¢16mm, the pellets are dried in a muffle furnace at 105℃ for 4 hours, and the temperature is rapidly raised to 1230℃ in the rotary kiln for oxidation pellets, and sintering is continued for 15min. Obtain high temperature oxidation pellets at 1230°C;

[0060] (2) Get the 1230 DEG C high-temperature oxidation pellets of step (1), add anthracite with 40% high-temperature oxidation pellet weight and a particle size of 0-10mm (its chemical composition is 59.20% fixed carbon and 8.41% ash by mass percentage) %, volatile ...

Embodiment 3

[0062] (1) Take Liaoning Chaoyang grade TFe:70.02% magnetite powder with a fineness of -200 mesh accounting for 80%, mix it with starch syrup with 2.0% iron ore powder weight, moisten and grind, and pelletize. The pellet size is ¢ 8 to ¢16mm, dried in a muffle furnace at 105°C for 4 hours, rapidly raised to 1200°C in an oxidized pellet rotary kiln, and sintered for 18 minutes to obtain 1200°C high-temperature oxidized pellets;

[0063] (2) Get the 1200 ℃ high-temperature oxidation pellet of step (1), add the anthracite (its chemical composition is 69.12% by mass percent of fixed carbon, and ash content is 15.14% of high-temperature oxidation pellet weight 45%), particle size 0-15mm %, volatile matter 12.6%, S 2.14%), mixed and roasted at 1050°C for 20min, added to the rotary kiln for deep reduction of flame-trap type, and carried out deep reduction reaction at 1075°C for 3.0h, took out the pellets, and weighed 45% of the coal powder was added to cover and cool, and the coal ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com