Preparation method of mesophase carbon microspheres with different particle sizes

A mesophase carbon microsphere and particle size technology, which is applied in carbon preparation/purification, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of non-adjustable particle size, environmental pollution, high cost, etc., and achieve easy production and operation , prevent environmental pollution, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

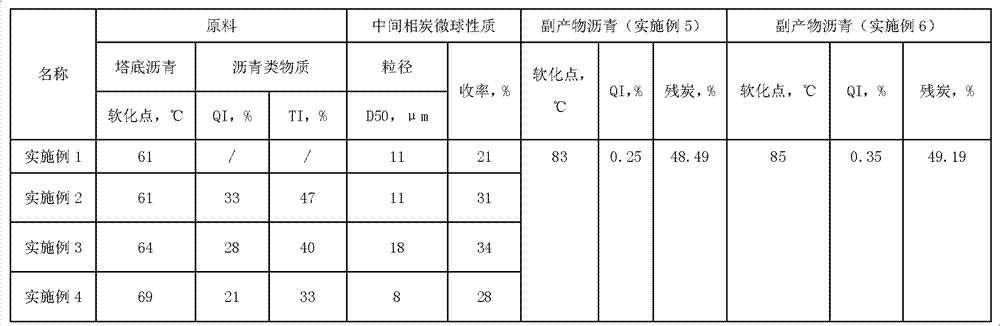

Embodiment 1

[0035] The tower bottom bitumen with a softening point of 61°C was used as the reaction raw material, heated to 410°C at a heating rate of 80°C / h, the N2 flow rate was 90 liters / hour, the temperature was maintained for 3 hours, and the stirring rate was 150 rpm. Heating and extracting with washing oil distillate as solvent, filtering three times to separate the solid, and drying at about 250°C under vacuum conditions to obtain mesophase carbon microspheres with a D50 of 11 μm, with a yield of 21%.

Embodiment 2

[0037]Mix the asphalt at the bottom of the tower with a softening point of 61°C with the asphalt containing 33% QI and 47% TI to obtain asphalt containing 10% quinoline insolubles and 18% TI as the reaction raw material, and heat up at 80°C / h The heating rate was 410° C., the N2 flow rate was 90 liters / hour, the temperature was maintained for 3 hours, and the stirring rate was 150 rpm. Heating and extracting the washed oil distillate as a solvent, filtering three times to separate the solid, and drying at about 250°C and a pressure of 0.02MPa to obtain mesophase carbon microspheres with a D50 of 11μm, with a yield of 31%.

Embodiment 3

[0039] Proportioning the tower bottom asphalt with a softening point of 64°C and the asphalt containing 28% QI and 40% TI to obtain asphalt containing 5.6% quinoline insolubles and 13% TI as the reaction raw material, the temperature is programmed at 60°C / h Control the heating rate to 420°C, the N2 flow rate is 90 liters / hour, the temperature is maintained for 4 hours, and the stirring rate is 100 rpm. Heating and dissolving with washing oil distillate as a solvent, filtering three times to separate the solid, and drying at about 250°C and a pressure of 0.02MPa to obtain mesophase carbon microspheres with a D50 of 18μm, with a yield of 34%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com