Density control equipment for aquatic puffed pellet feed

A technology of extruded pellet feed and density control, applied in feed, metal processing, food science and other directions, can solve the problems of light density and low bulk density, easy to float, etc., and achieve the effect of increasing bulk density and compact particle structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

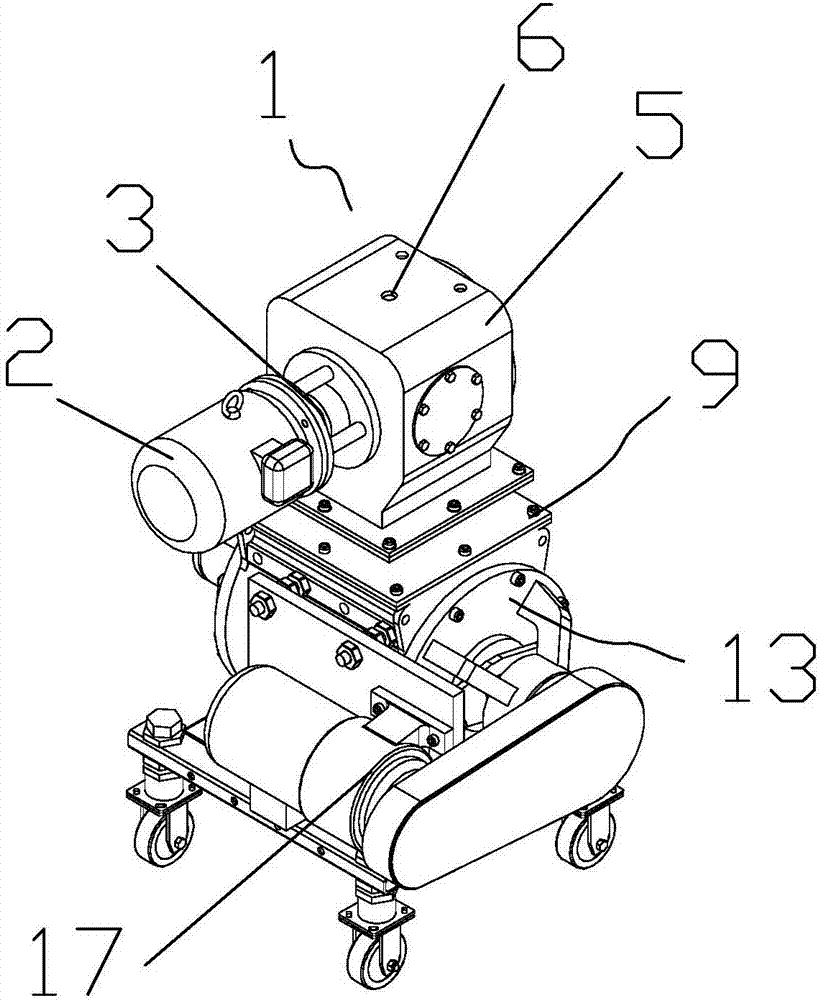

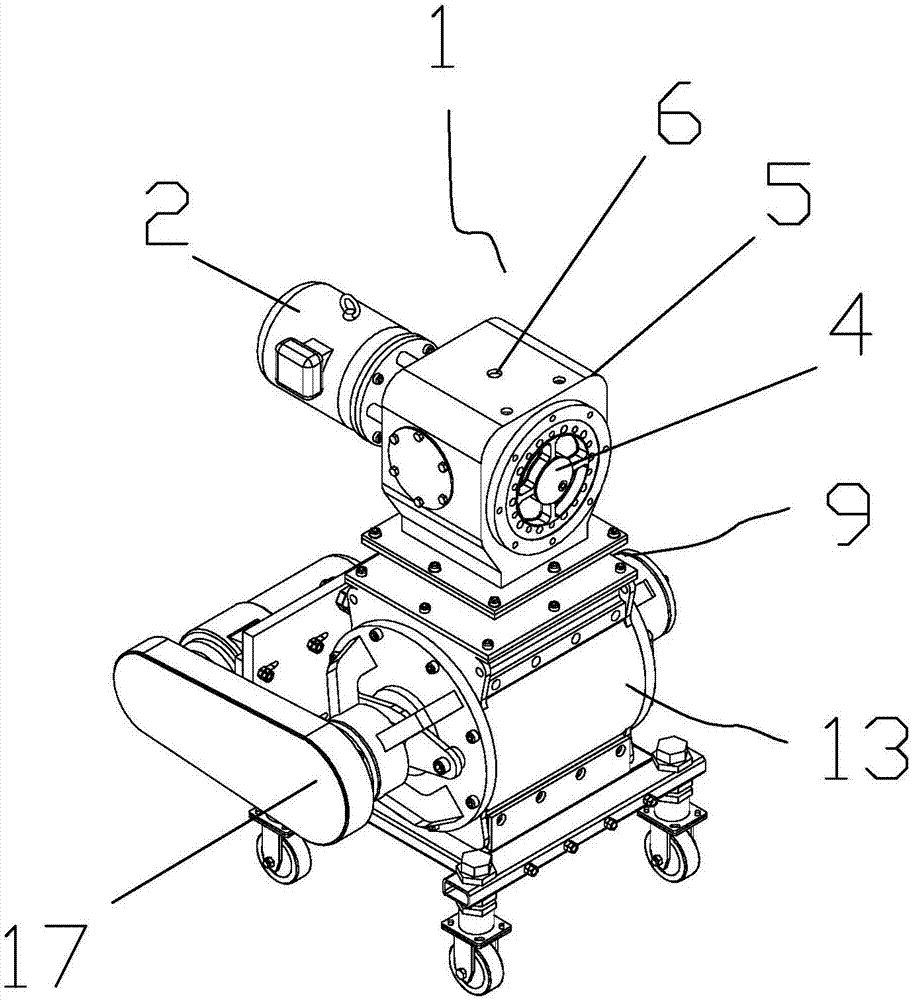

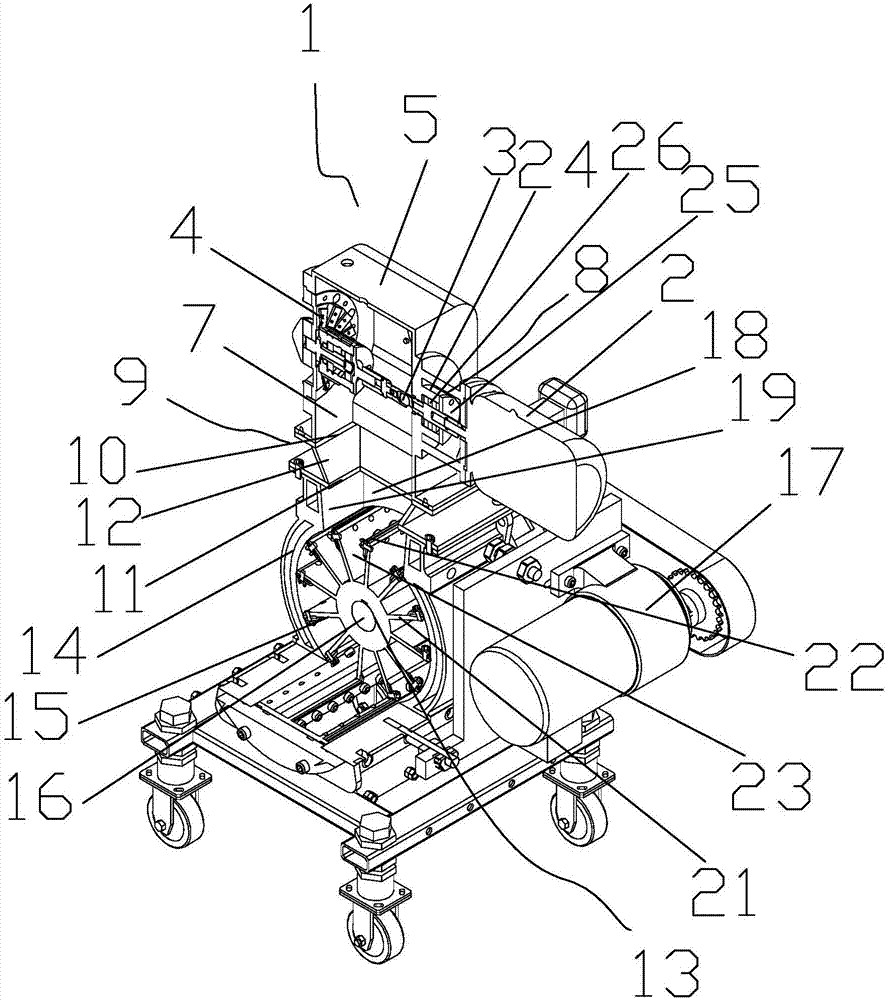

[0038] exist figure 1 , figure 2 , image 3 In the illustrated embodiment, a device for controlling the density of aquatic extruded pellet feed includes:

[0039] Material cutting device 1 is used to cut the puffed pellets coming out of the puffing cavity into granules; material cutting device 1 includes power part 2, transmission part 3, cutter device 4 and cutter housing 5, the upper end of cutter housing 5 A pressurizing hole 6 is provided, and the lower end of the cutter housing 5 is provided with a discharge opening 7; the cutter device 4 is arranged inside the cutter housing 5 and drives the material cutting through the power part 2 and the transmission part 3, and the power part 2 and the transmission part 3 drive the cutting material. The cutter housings 5 are arranged at intervals, and a multi-layer sealing structure 8 is arranged between the power part 2 and the cutter housings 5;

[0040] The buffer feeding device 9 is used for buffering the falling particles;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com