Composite binder and powder pellet obtained through same

A binder and pellet technology, applied in the field of composite binders, can solve the problems of lack of research on the preparation process route of magnesium oxide pellets, and achieve the effects of broad industrialization prospects, improved density and strength, and convenient feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

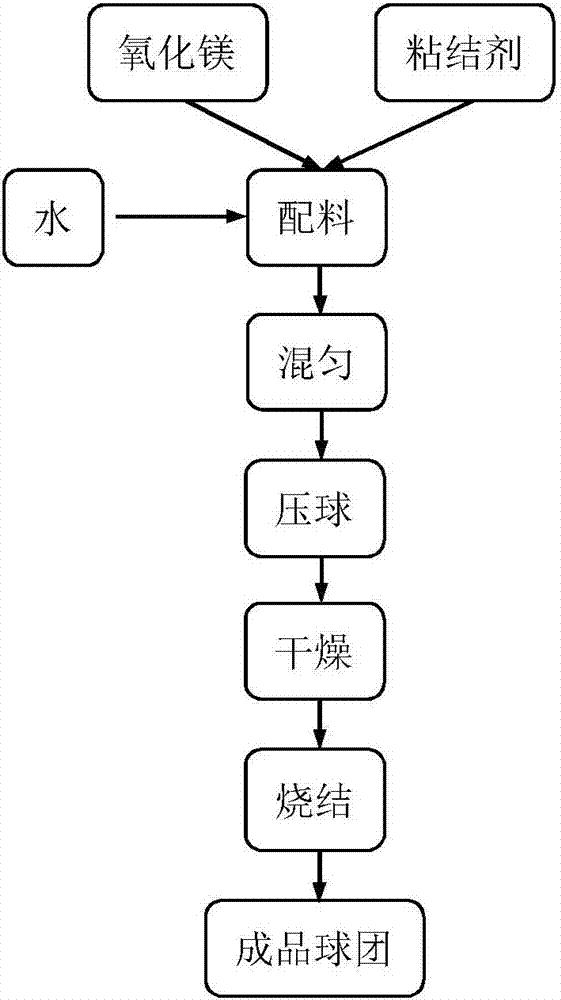

Method used

Image

Examples

preparation example Construction

[0117] According to the preparation method of the present invention, the green balls need to be dried before sintering, so that the green balls can withstand the temperature stress and anti-dropping ability of subsequent sintering, so as to avoid the destruction of the pellet structure. The drying is carried out in an oven, the drying temperature is 100-150°C, and the drying time is 5-7h.

[0118] According to the preparation method of the present invention, in order to crystallize magnesium oxide, grain growth is promoted. In the present invention, the sintering temperature is 1000-1300° C. and the time is 10-30 minutes, which can make the magnesium oxide pellets have higher strength.

Embodiment 1

[0121] This example is used to illustrate the magnesium oxide pellet binder and the pellet preparation method thereof of the present invention.

[0122] The magnesium oxide purity of used magnesium oxide powder raw material is the MgO of 92.5wt%, with sodium carboxymethyl cellulose 20g, humic acid 30g, cornstarch 30g, acrylic resin 30g, syrup 20g, polyvinylpyrrolidone 20g, polyacrylamide 20g, 40g of sodium silicate, 40g of slaked lime and 0.9kg of water are prepared into colloidal binder and mixed with 8.8kg to obtain a mixture.

[0123] The mixture was poured into a briquetting machine, and the briquettes were pressed using a briquetting machine (molding pressure 10 MPa) to obtain green pellets with a size of Φ30×15 mm. Then the green pellets were dried in an oven at a drying temperature below 100° C. for 5 hours to obtain dry pellets. Place the dry pellets in a temperature-programmed furnace, raise the temperature to 1100°C at a rate of 4°C / min, keep the temperature constan...

Embodiment 2

[0125]This example is used to illustrate the magnesium oxide pellet binder and the pellet preparation method thereof of the present invention.

[0126] The magnesium oxide purity of used magnesium oxide powder raw material is the MgO of 94.4wt%, with sodium carboxymethylcellulose 30g, humic acid 40g, cornstarch 40g, acrylic resin 30g, syrup 40g, polyvinylpyrrolidone 30g, polyacrylamide 35g, 50g of sodium silicate, 45g of slaked lime and 1.0kg of water are prepared into colloidal binder and mixed with 8.7kg to obtain a mixture.

[0127] The mixture was poured into a briquetting machine, and the briquettes were pressed using a briquetting machine (molding pressure 15 MPa) to obtain green pellets with a size of Φ30×15 mm. Then the green pellets were dried in an oven at a drying temperature below 100° C. for 5 hours to obtain dry pellets. Place the dry pellets in a temperature-programmed furnace, raise the temperature to 1200°C at a rate of 4°C / min, keep the temperature constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com