Method and device for pelletizing unprocessed cellulosic fibrous material

a cellulosic fibrous material and unprocessed technology, applied in the direction of manufacturing tools, combustion types, lighting and heating apparatuses, etc., can solve the problems of increasing the price of raw materials, reducing the desirability of wood as a renewable energy source, and many losses, so as to achieve high calorific value and high fire risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0144] The method and the setup of the device as claimed in the present application has been achieved through tests at our pilot pelletization plant, using the following equipment:

[0145] One carbon steel grain hopper to receive and store raw material, with 9 m3 capacity.

[0146] One screw transporter, with a 10-12 metric ton / hour capacity, driven by a 5 hp at 1,750 rpm motor, to feed the vibrating sifter.

[0147] One vibrating sifter, with a 10-12 metric ton / hour capacity, driven by a 5 hp at 1,750 rpm motor, to separate the unprocessed sugar-cane bagasse.

[0148] One screw transporter, with a 10-12 metric ton / hour capacity, driven by a 5 hp at 1,750 rpm motor, to feed the dryer.

[0149] One spinning tube dryer, with a 10-12 metric ton / hour capacity, driven by a 7.5 hp at 1,750 rpm motor.

[0150] One hot-gas exhaust, with a 1,000 m3 / hour capacity, driven by a 25 hp at 1,750 rpm motor.

[0151] One cyclone to separate dust, with a 5 metric ton / hour capacity.

[0152] One fan to insufflate ho...

working example

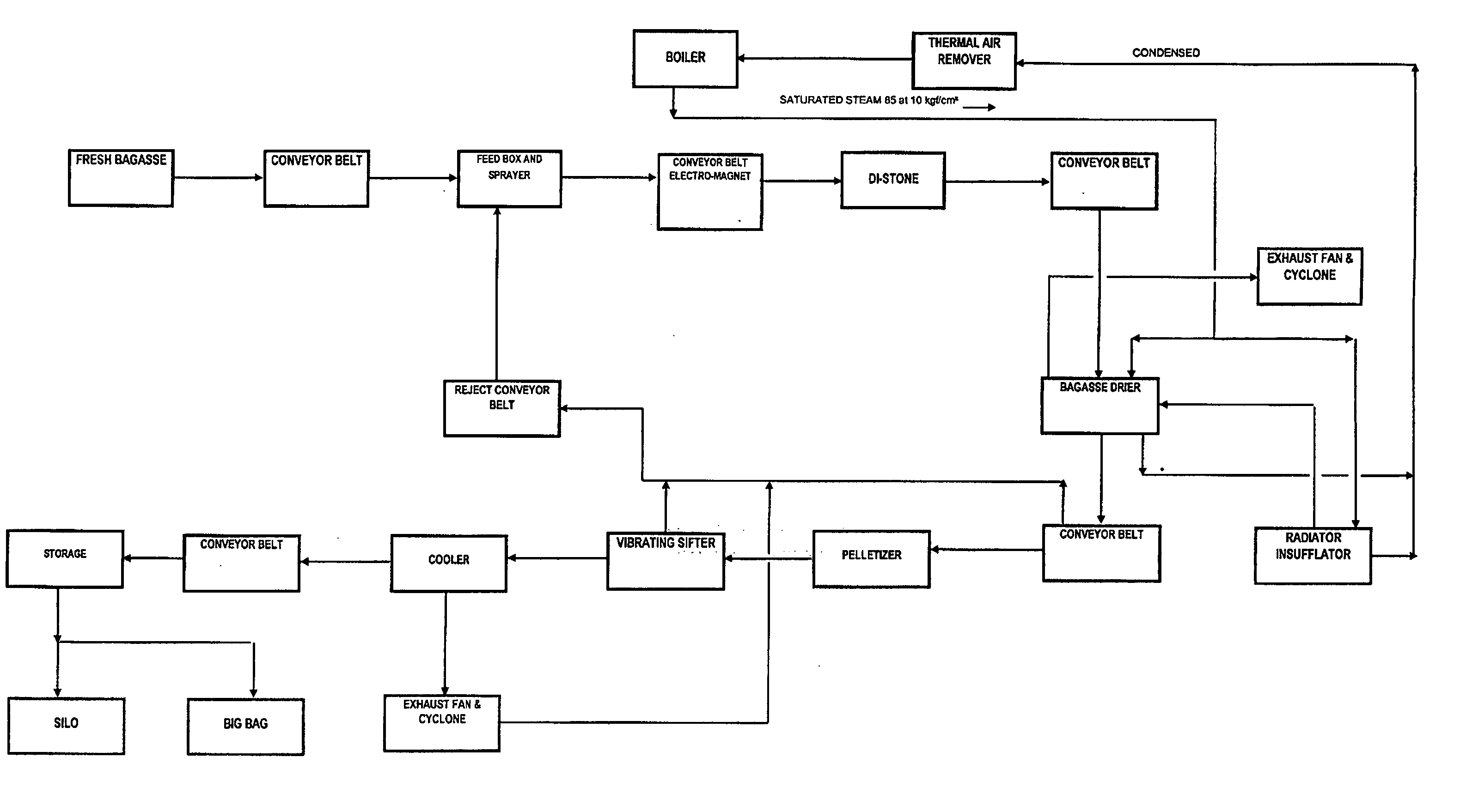

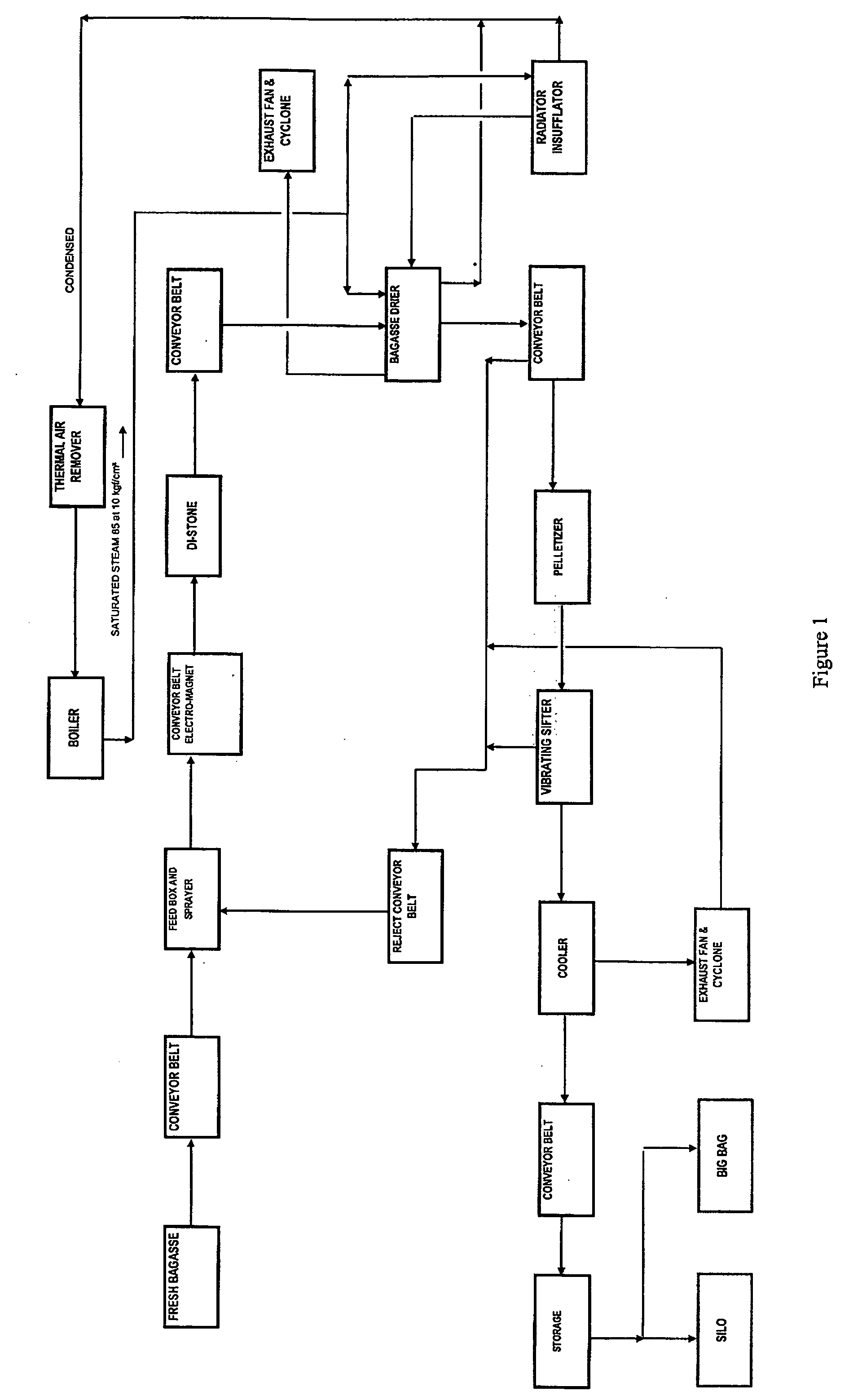

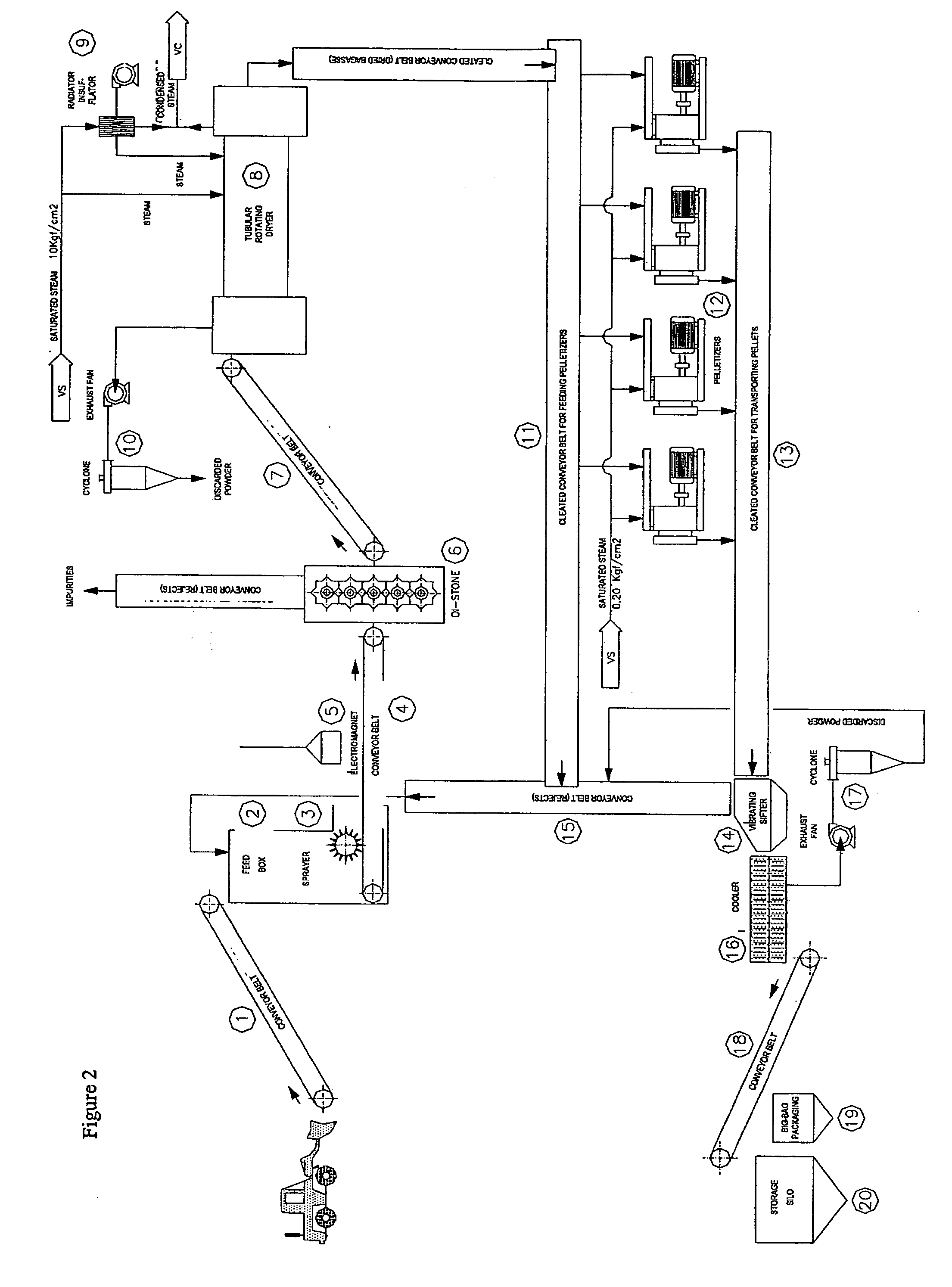

[0168] With reference to FIG. 1 and the listing of material as above, sugar-cane bagasse is first continuously fed into a feed box (2), and loosened and flattened by a sprayer (3). The feed box can hold a 15-minute supply in relation to the plant output capacity and has a cleated type conveyor belt to transport the unprocessed sugar-cane bagasse. Then, ferrous material and impurities of the unprocessed sugar-cane bagasse are removed by an electromagnet (5) with a minimum magnetic capacity of 1,500 gauss, and any other impurities are removed by a di-stone (6) consisting of 5 to 8 perpendicular axes with star-shaped knives that counter rotate.

[0169] Then, the unprocessed sugar-cane bagasse is dried in a spinning tube dryer (8) using a system of bundled tubes conveying saturated steam at 9 kgf / cm2, at a temperature of about 175° C. inside the tube, providing indirect contact with the product in the tube's external wall (i.e. the steam inside the pipes dry without contact with the baga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com