Slurry-spraying rotary granulator

A granulator and spraying technology, which is applied in the direction of granulation, fertilizer mixture, fertilizer form, etc. in the rotary tank, can solve the problems that the rotary drum granulator cannot be dried, the product granules have high moisture content, deformation, etc., and achieve improvement The effect of external working environment, reducing energy consumption, and sufficient material mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

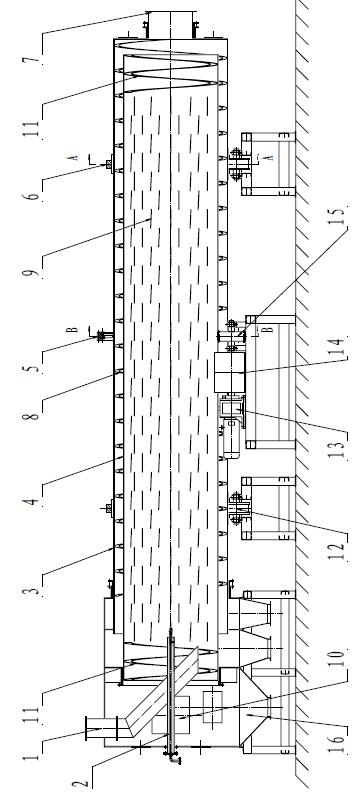

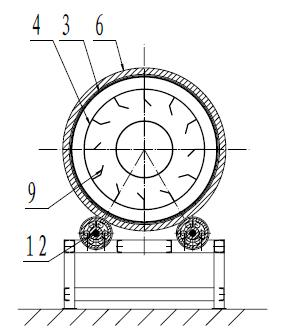

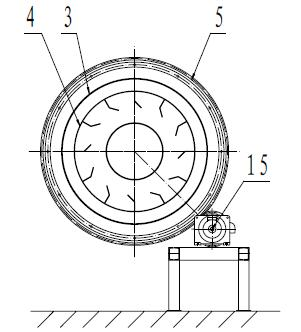

[0022] Embodiment: a kind of shotcrete rotary granulator that is used to coat the charcoal layer outside granular fertilizer, such as Figure 1 to Figure 4 shown. The device includes a coaxially arranged horizontal outer cylinder 3 and an inner cylinder 4, the inner cylinder 4 and the outer cylinder 3 rotate synchronously, and the left end of the inner cylinder 4 is provided with an air chamber communicating with the inner cylinder 4, and the air chamber is also provided with An air inlet 10 is arranged, and other places of the air chamber are all closed. The left end of the inner cylinder 4 is also provided with a feed inlet 1 and a spray gun 2, both of which pass through the air chamber to communicate with the outside, and are sealed at the penetrations, and the feed inlet 1 is used to add to the inner cylinder 4. Granular fertilizer and charcoal powder to be coated, spray gun 2 is used for spraying binder.

[0023] The left and right ends of the inner wall of the inner cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com